Electrodialysis spacer

An electrodialysis and separator technology, applied in the field of water treatment, can solve the problems of leakage and leakage in the flow channel, and achieve the effects of good sealing, lower resistance and large Reynolds number.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

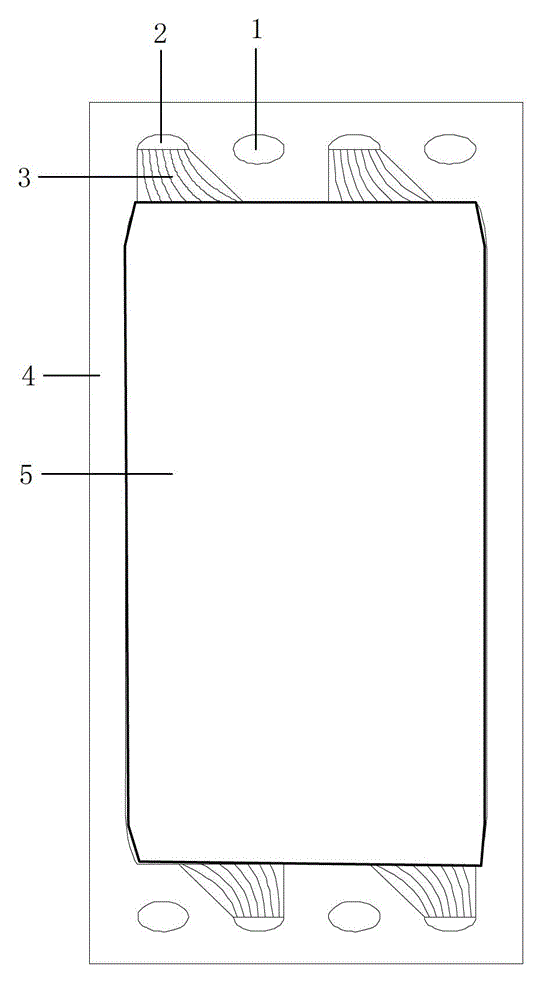

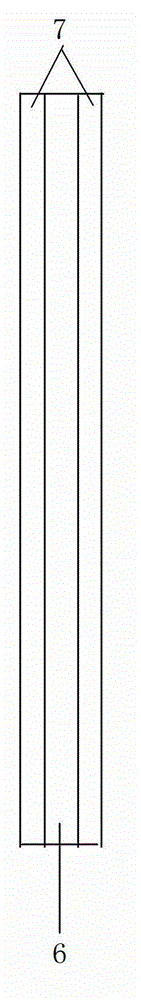

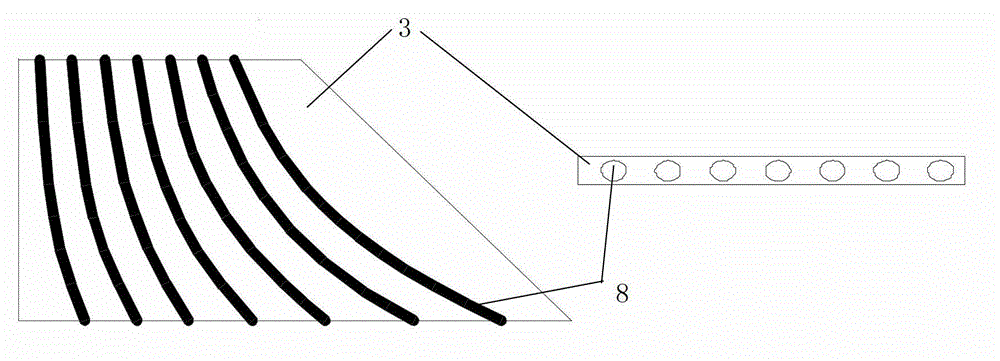

[0025] According to attached figure 1 , attached figure 2 As shown in the structure, an electrodialysis separator is made, and the plate frame for making the separator is made of a PP sheet with a thickness of 0.4mm. It is 400mm long and 200mm wide. The thickness of the elastic layer 7 on both sides is 0.15mm, and the total thickness is 0.70mm. mm; the elastic layer 7 is blended with 50% tetrafluoroethylene and 50% polyethylene. Including plate frame body 4, water distribution channel 3, liquid guide hole, plate core partition 5, half of the liquid guide holes are oval liquid guide holes 1, and the other half of the number of liquid guide holes are semi-elliptical liquid guide holes 2 is connected with the water distribution flow channel 3, alternately with each other, and penetrates with the inner cavity of the plate frame body 4, and there are half the number of oval liquid guide holes 1 at one end of the plate frame body 4, and the inner cavity of the plate frame body 4 i...

Embodiment 2

[0029] In a similar manner as in Example 1, the panel frame of the partition is made of a PP sheet with a thickness of 0.4mm, its length is 800mm, and its width is 400mm. The elastic layers shown on both sides have a thickness of 0.2mm and a total thickness of 0.80mm; the elastic layer is made of 40 mm. % tetrafluoroethylene blended with 60% polyethylene. The plate core spacer 5 adopts the PP elastic spacer specially used for the flow channel, which is 360×700mm and the thickness is 0.80mm. There are 50mm plate surfaces at both ends of the plate frame, and 3 oval liquid guide holes are opened on the plate surface. 1, 3 semi-elliptical liquid guide holes 2, the major axis of the elliptical hole is 40mm, the short axis is 20mm, the semi-elliptical liquid guide hole 2 at one end of the plate frame 4 is the water inlet channel, and the other end is semi-elliptical liquid guide hole 2 is the water outlet channel, and the semi-elliptical liquid guide holes 2 at each end are alternat...

Embodiment 3

[0032] Similar to the way of making the partition as in Example 1, the panel frame 4 for making the partition is made of a PP sheet with a thickness of 0.5mm, its length is 1600mm, and its width is 800mm. Both sides show that the thickness of the elastic layer is 0.2mm, and the total thickness is 0.80mm. ; The elastic layer is blended with 60% tetrafluoroethylene and 40% polyethylene. The board core partition adopts the special PP elastic partition for the flow channel, which is 640×1500mm and the thickness is 0.90mm. There are 50mm board surfaces at both ends of the board frame body 4, and 5 oval liquid guide holes are opened on the board surface. 1, 5 semi-elliptical liquid guide holes 2, the major axis of the elliptical hole is 50mm, and the short axis is 30mm. 2 is a water outlet channel, and the semi-elliptical liquid guide holes 2 at each end are alternately provided with hollow elliptical flow channels 8 connected to the plate core separator 5, and the major axis of eac...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com