Flaky object separate-taking mechanism and method

A technology for sheet objects and extraction holes, which is applied in the field of sheet object separation mechanisms, can solve the problems of increasing product production costs, expensive static electricity removal devices, and high maintenance costs, and achieve reduced production costs, equipment costs, and maintenance costs Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

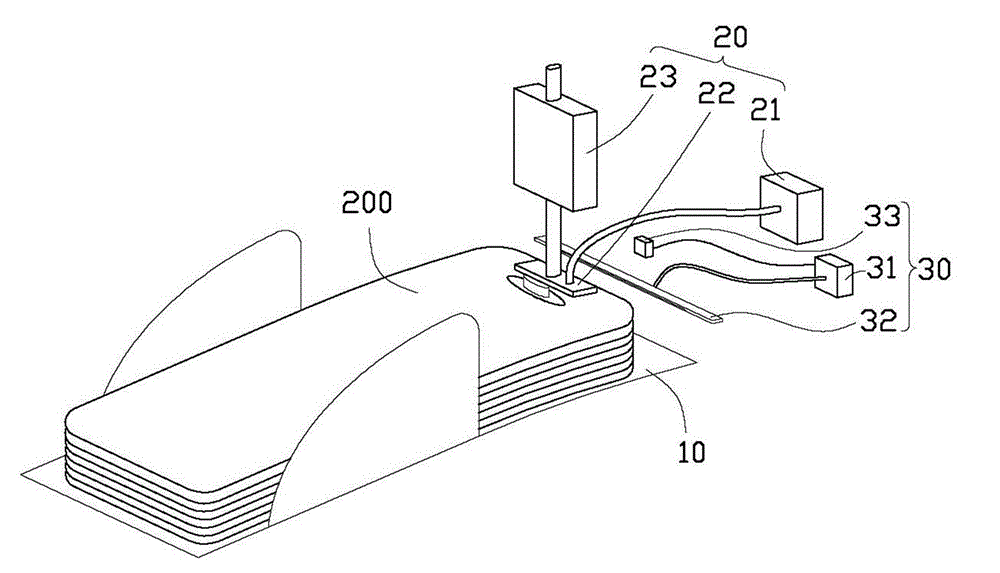

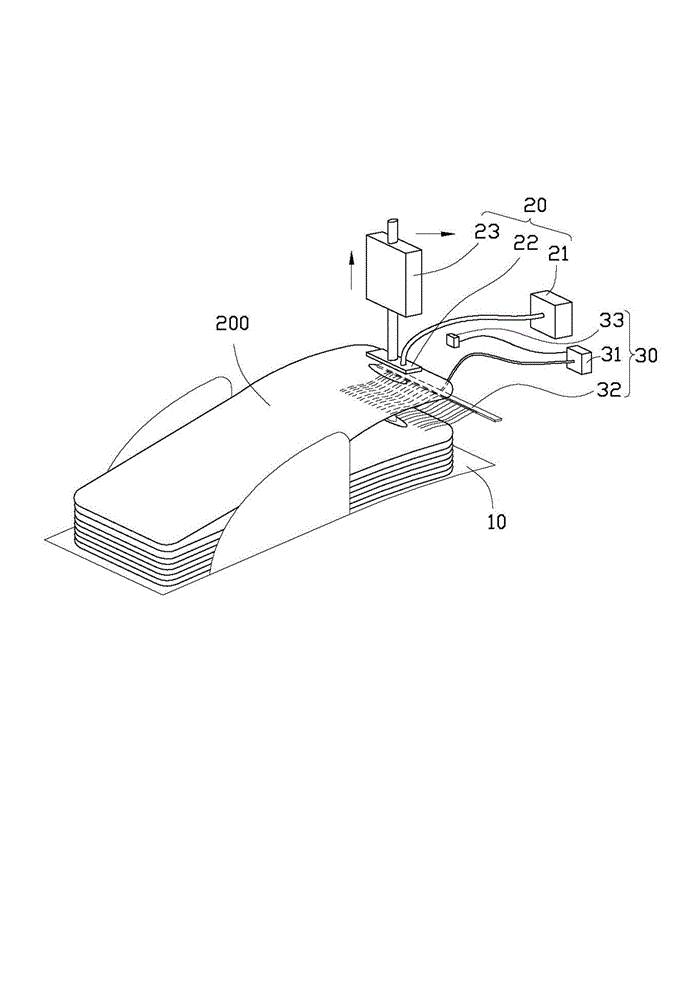

[0014] It needs to be explained first that in the present invention, the so-called sheet-like objects include packaging bags, packaging films, etc., which are generally sheet-shaped substances that are prone to electrostatic adsorption between each other during the separation process. , the sheet is a packaging bag 200 .

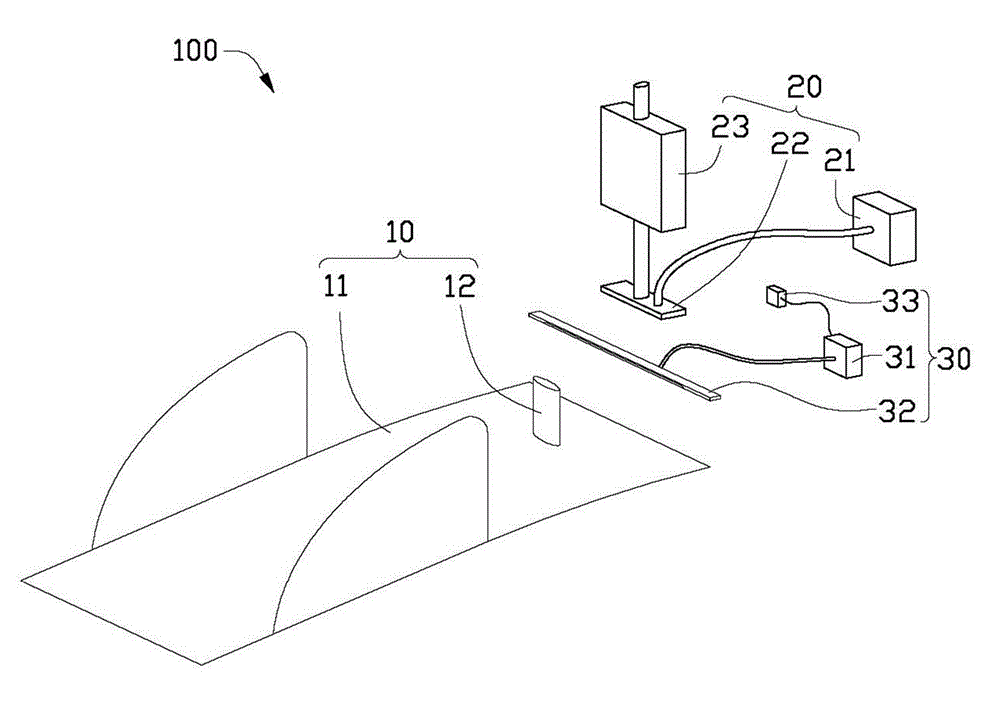

[0015] Please also see Figure 1 to Figure 3 As shown, the sheet sorting mechanism 100 provided by the embodiment of the present invention includes a carrying unit 10 , a sorting unit 20 and an air blowing unit 30 .

[0016] The carrying unit 10 is used to carry the packaging bag 200 to be picked up.

[0017] In this embodiment, the carrying unit 10 is roughly rectangular, and includes a carrying surface 11 for stacking the packaging bags 200 to be picked up. Usually, extraction holes are provided on the packaging bag of the product to facilitate extraction by the user. Therefore, in this embodiment, the bearing surface 11 is also provided with a positioni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com