A kind of board making equipment

A technology of equipment and racks, which is applied in the field of fireproof insulation board manufacturing equipment, can solve the problems of affecting the transportation speed of fireproof insulation boards, the thickness cannot be adjusted, and cannot be adjusted, so as to achieve simple structure, avoid slipping, and avoid adjustment lag Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] The present invention will be described in further detail below in conjunction with the accompanying drawings, but it is not intended to limit the protection scope of the present invention.

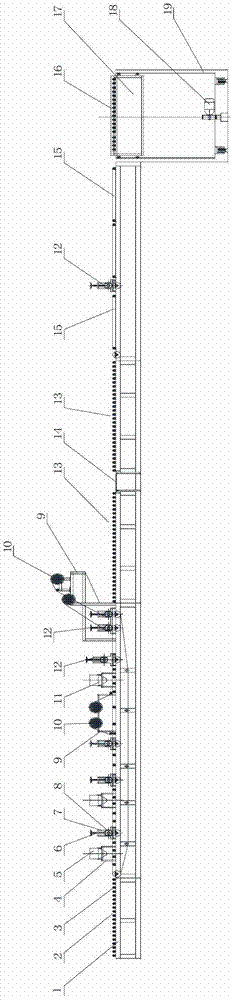

[0020] Such as figure 1 As shown, a plate making equipment includes a frame 1, and the frame includes a production conveying system 2, a rolling and rotating system, a chain rotating system and a lifting and conveying system in sequence.

[0021] In the present invention, the production conveying system includes several uniformly arranged transmission shafts 3 arranged on the frame, and generally the number of transmission shafts 3 is 20-30.

[0022] In the present invention, the rolling and rotating system includes several material discharge adjustment devices and several cloth discharge adjustment devices arranged on the frame 1 . The material discharging adjustment device includes a material discharging device 11 and a thickness adjusting device 12 , and the cloth releasing adj...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com