EU-1/ZSM-5 composite molecular sieve, and catalyst for toluene disproportionation and transalkylation and application of catalyst

A composite molecular sieve, ZSM-5 technology, applied in molecular sieve catalysts, physical/chemical process catalysts, chemical instruments and methods, etc., can solve the problems of increasing catalyst costs and increasing catalyst preparation steps, and achieve low catalyst costs and simple preparation methods , to reduce the effect of the secondary reaction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The preparation method of catalyst of the present invention comprises the following contents:

[0032] The hydrogen type EU-1 / ZSM-5 composite molecular sieve is kneaded with inorganic refractory oxide, peptizing acid, extrusion aid, etc., and then dried and calcined to obtain the catalyst. Inorganic refractory oxides can be selected from one or more of alumina, titania, silica, boria, magnesia, zirconia and clay, preferably alumina and / or silica, more preferably alumina . Its precursor can be selected from one or more of boehmite, pseudo-boehmite, diaspore, gibbsite and bayolite, preferably pseudo-boehmite; peptizing acid such as Nitric acid, hydrochloric acid, acetic acid, citric acid, etc., preferably nitric acid; the extrusion aid is a material that is beneficial to extrusion molding, such as graphite, starch, cellulose, celadon powder, etc., preferably celadon powder.

[0033] The preparation process of hydrogen-type EU-1 / ZSM-5 composite molecular sieve is to prep...

Embodiment 1

[0040] (1) Synthesis of EU-1 / ZSM-5 composite molecular sieve

[0041] Add TPAOH, TPABr (mass ratio 1:1), distilled water to the beaker, stir evenly, then add EU-1 molecular sieve seeds, stir for 10 min, and finally add silica sol, stir for 30 min, and then put into the synthesis kettle. Heating at 120°C for 48h in an oven, filtering the obtained product, washing with distilled water until neutral, drying, and calcining at 550°C for 6h to obtain EU-1 / ZSM-5 composite molecular sieve.

[0042] The material ratio in the synthetic material is:

[0043] EU-1 / SiO 2 (g / g) = 1.5;

[0044] R / SiO 2 (mol / mol) = 0.3;

[0045] H 2 O / SiO 2 (mol / mol) = 55.

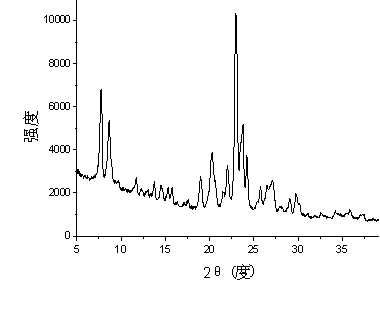

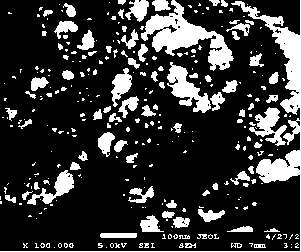

[0046] The XRD pattern and scanning electron microscope photo of the EU-1 / ZSM-5 composite molecular sieve are as follows figure 1 , 2 shown. from figure 1 It can be seen that the characteristic peaks of EU-1 molecular sieve and ZSM-5 molecular sieve in the composite molecular sieve are quite obvious. from figure 2 It can be ...

Embodiment 2

[0053] Take 75 grams of hydrogen-type EU-1 / ZSM-5 composite molecular sieve prepared in Example 1, 104.2 grams of SB powder, and 3.75 grams of Asparagus powder, mix well, then add 85 ml of deionized water and 3.75 ml of concentrated nitric acid (66.5w%) Fully kneaded on a roller compactor to make it into a paste-like plastic, extruded a cylindrical bar with a diameter of 1.5 mm on an extruder, dried at 110°C for 8 hours, and then calcined at 550°C for 4 hours in an air atmosphere to obtain catalyst C2. The catalyst composition and evaluation results are shown in Table 2.

PUM

| Property | Measurement | Unit |

|---|---|---|

| pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com