Screen rolling device for greenhouse

A technology of roller blinds and roller shutter shafts, which is applied in horticulture, greenhouse cultivation, climate change adaptation, etc. It can solve problems such as laborious, time-consuming, and unsteady rolling and lowering of roller blinds, so as to improve the efficiency of roller blinds, roll up and down. Safe laying down and smooth axial movement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

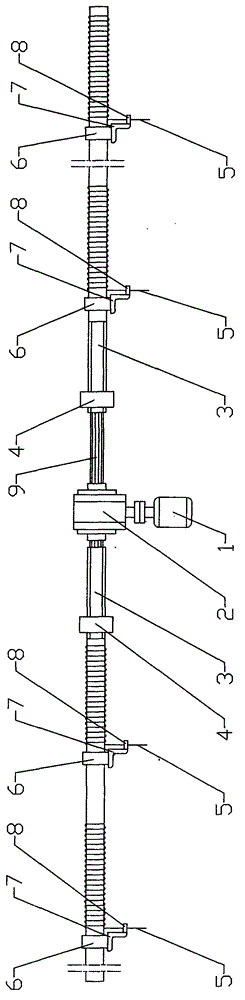

[0014] As shown in the drawings, a greenhouse roller blind device includes a motor 1 and a reducer 2, the motor 1 is connected to the input shaft of the reducer 2, and the two ends of the output shaft 9 of the reducer 2 are respectively connected with roll The curtain shaft 3, the output shaft 9 and the curtain shaft 3 are connected by splines, the end of the curtain shaft 3 close to the reducer 2 is provided with external threads, and the two sides of the reducer 2 are respectively provided with fixing seats 4 , the fixed seat 4 is threadedly connected with the roller shade shaft 3 .

[0015] The output shaft 9 is an external spline shaft, and the end of the shutter shaft 3 connected to the output shaft 9 has an internal spline.

[0016] The roller shade shaft 3 is provided with several supporting devices for supporting the roller shade shaft 3, and the supporting devices make the roller shade shaft 3 more stable, safe and reliable when rotating.

[0017] The support device ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com