Connecting assembly and axial-flow lampblack exhaust fan

A technology for electrical components and fume fans, applied in electrical components, oil fume removal, contact parts, etc., can solve problems such as time-consuming and laborious, wire breakage, and inability to connect wires.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

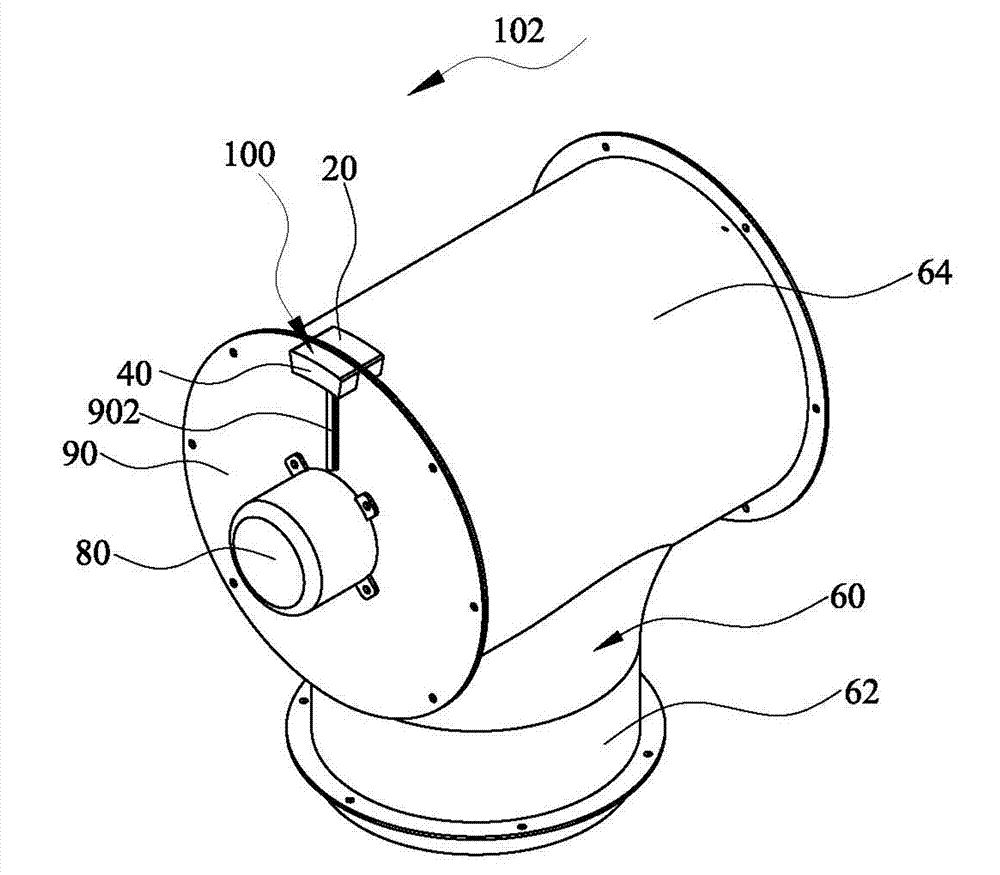

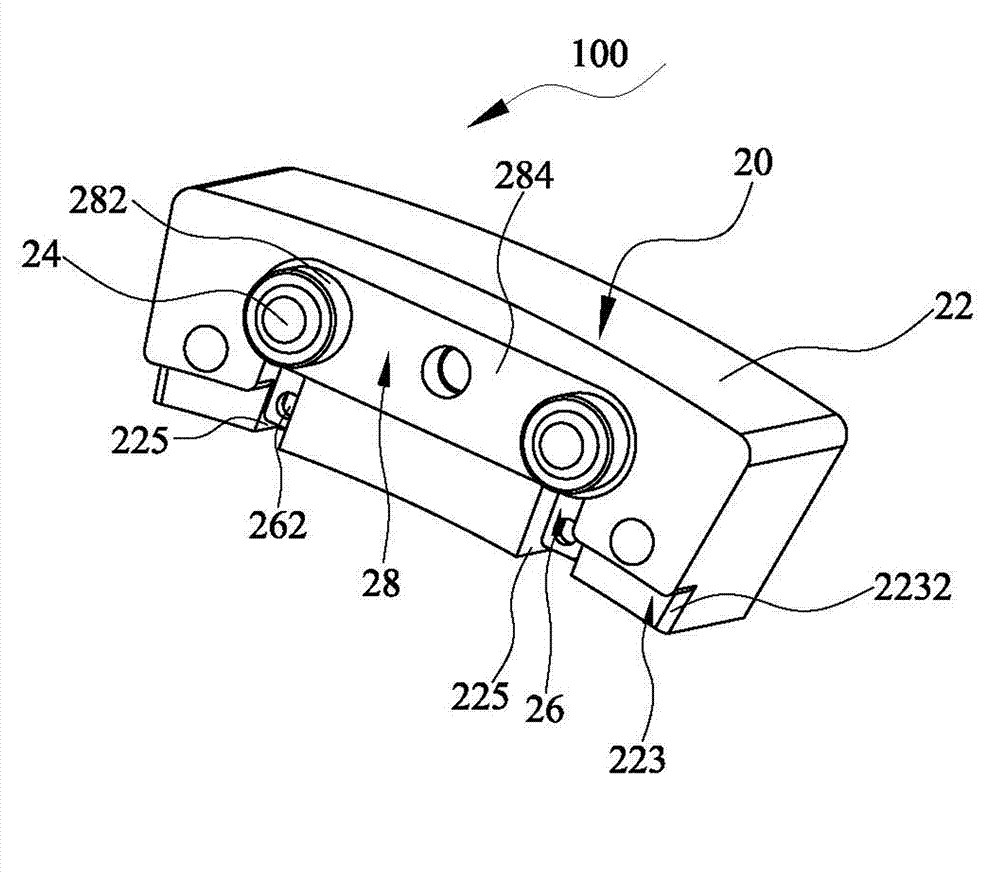

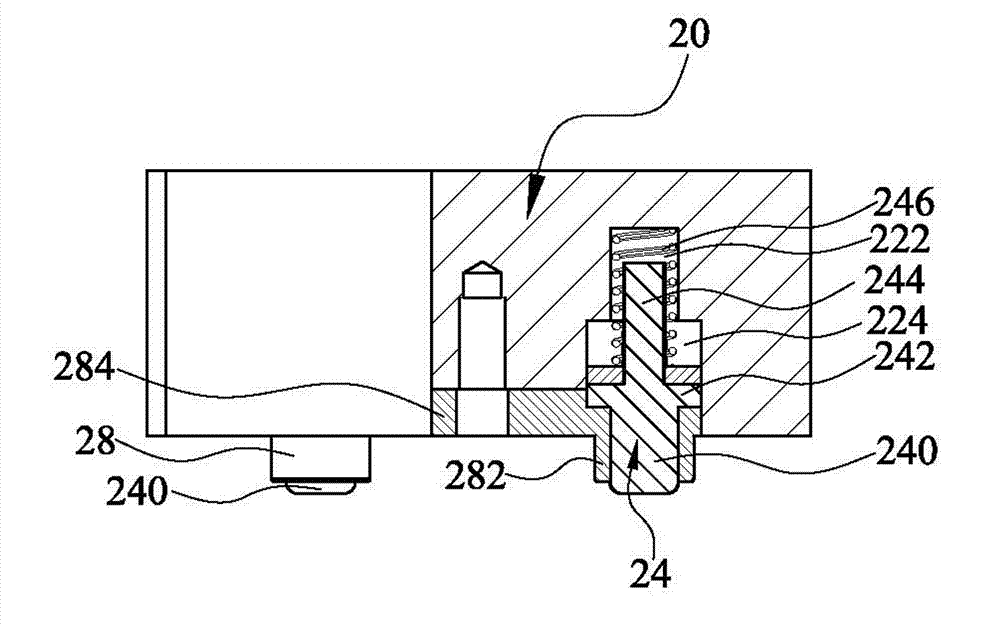

[0028] Such as Figure 2 to Figure 3 As shown, the power connection assembly 100 according to an embodiment of the present invention includes: a first connection module 20 . The first connection module 20 includes: a first socket 22 , a first nail 24 disposed on the first socket 22 , and a first strip 26 connected to the nail 24 .

[0029] The power connection assembly 100 of this embodiment further includes a second connection module 40 that is arranged correspondingly to the first connection module 20 and is butt-contacted.

[0030] The second connection module 40 includes: a second electric nail 44 corresponding to the first electric nail 24 and being electrically connected by bumping.

[0031] In this embodiment, the first electric nail 24 is a columnar structure. In order to facilitate installation and fixation, preferably the first electric nail 24 includes a plurality of columns with different cross-sectional sizes.

[0032]Further, the first electrical connection nai...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com