Pipeline for injecting pellets from strong field side

A technology for injecting pipelines and projectile strong fields, applied in nuclear reactors, nuclear power generation, climate sustainability, etc., can solve problems such as insufficient requirements for feeding materials, achieve the effect of improving feeding efficiency and enriching the content of physical experiments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0014] The present invention will be further described below in conjunction with accompanying drawing and specific embodiment:

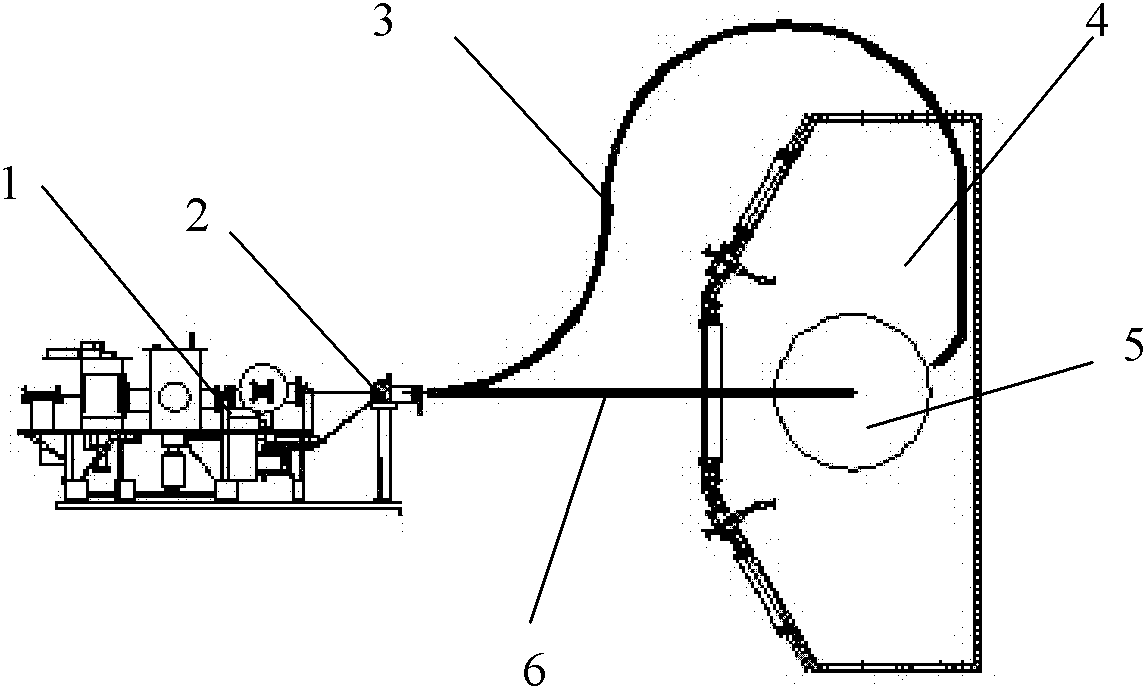

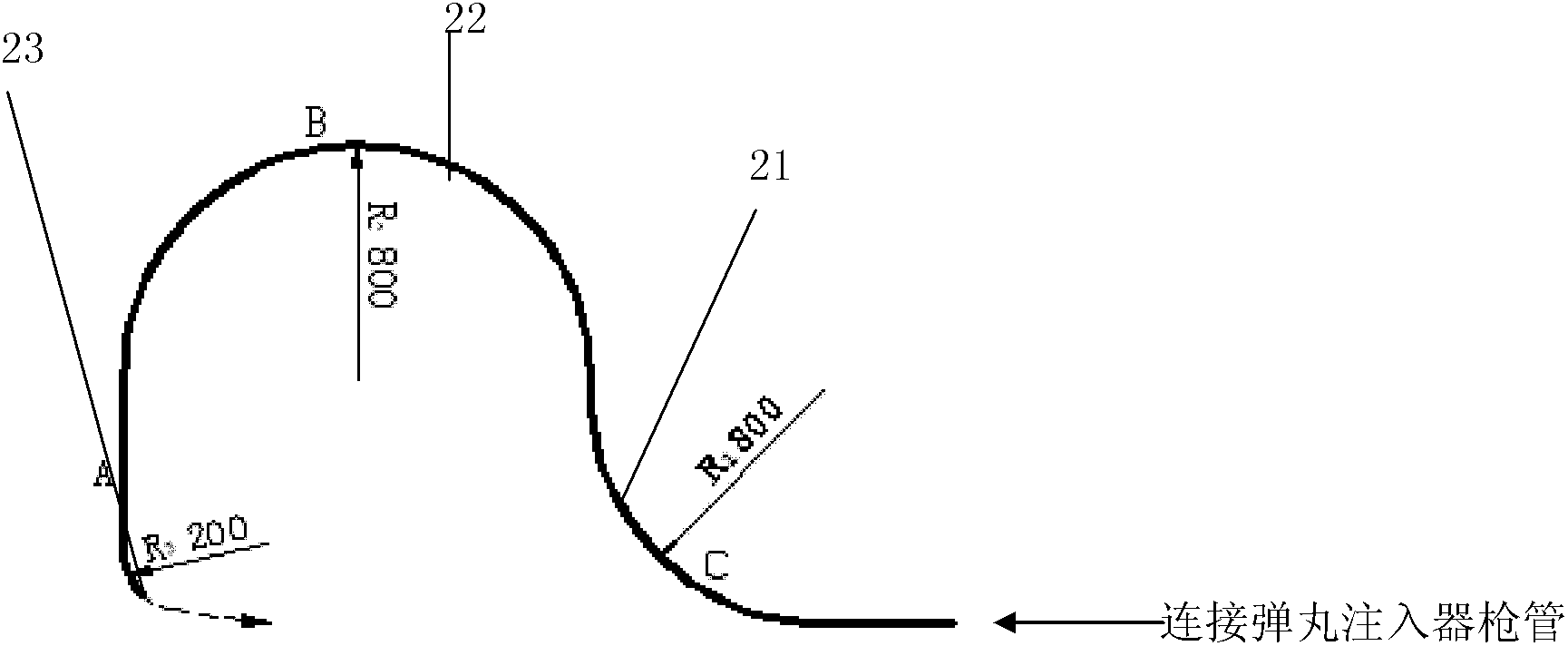

[0015] The overall structure of projectile injection on the strong field side and the weak field side is as follows: figure 1 As shown, the projectile injection pipeline design on the strong field side includes: three sections of curved conduits with different curvatures, converters, projectile diagnostic instruments (velocity measurement, imaging system), etc.

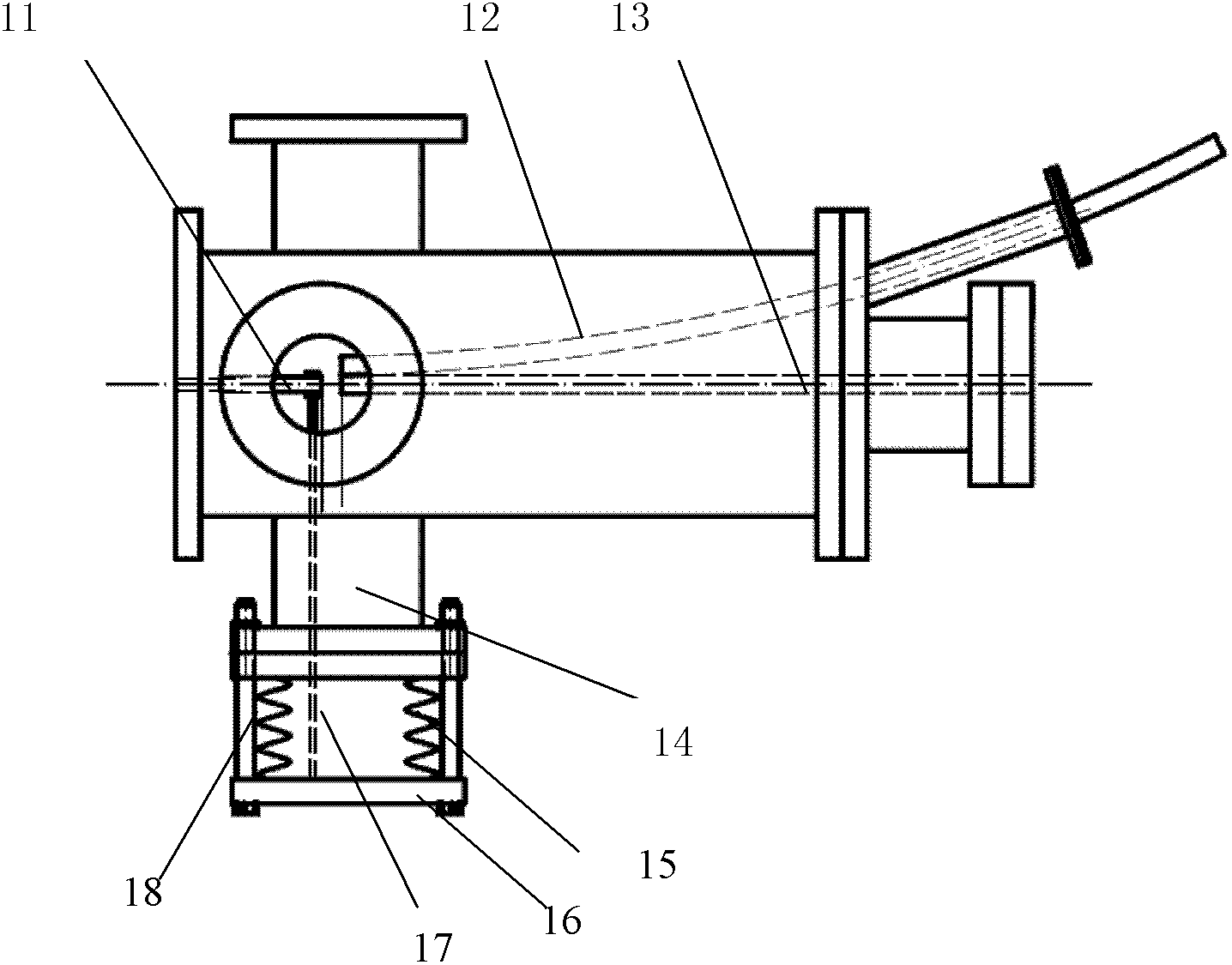

[0016] The function of the three-section curved conduit is to introduce the projectile from the outlet of the projectile injector barrel into the discharge vacuum chamber to realize the strong field injection of the projectile and ensure the integrity of the projectile in the curved conduit; the main function of the converter is to switch between strong and weak field injection The pipeline enables the flexible change of the projectile injection method; the projectile diagnostic instrument i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com