Method and system for compensating fixed tooth deviation

A compensation method and fixed tooth technology, applied in the direction of analyzing materials, instruments, etc., can solve the problems of reducing measurement efficiency, affecting the position of sample addition, reagent addition and stirring, etc., to improve measurement efficiency, eliminate inherent deviation, and improve positioning accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] In order to further describe the present invention, a more specific example is listed below for more detailed description. For example, the number of teeth on the reaction plate is one hundred and sixty.

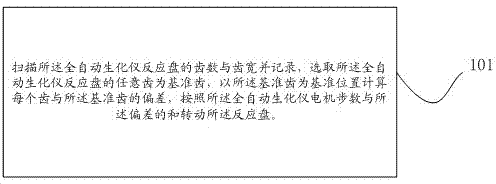

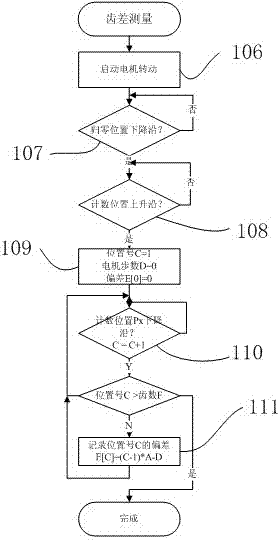

[0042] After power-on, the reaction panel control board immediately executes the tooth difference scan, and saves the tooth difference data of each position scanned in the random access memory;

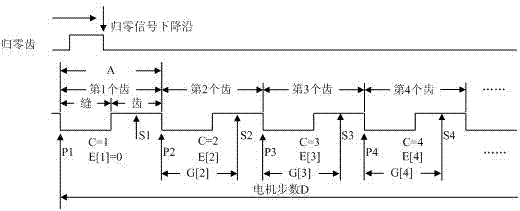

[0043] Start the motor and rotate at a constant speed in the test direction, such as figure 2 As shown, each tooth starts at low level and ends at high level, and the tooth count position and tooth deviation position are the edge positions from high level to low level; the slits and teeth of each tooth are configured 1:1 , If it is not this ratio, calculate according to the actual situation; create a character array, use 1-160 as the deviation of the corresponding tooth, and initialize it to zero;

[0044] Select the first tooth after the zero point of the automatic biochemical ana...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com