Blast protection mixed flow blower for ship

A mixed-flow fan and marine technology, which is applied to the components, mechanical equipment, machines/engines, etc. of the pumping device for elastic fluids, can solve problems such as the inability to meet the high performance requirements of marine equipment, and achieve good aerodynamic characteristics, The effect of improving fan performance and ventilation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the drawings and embodiments.

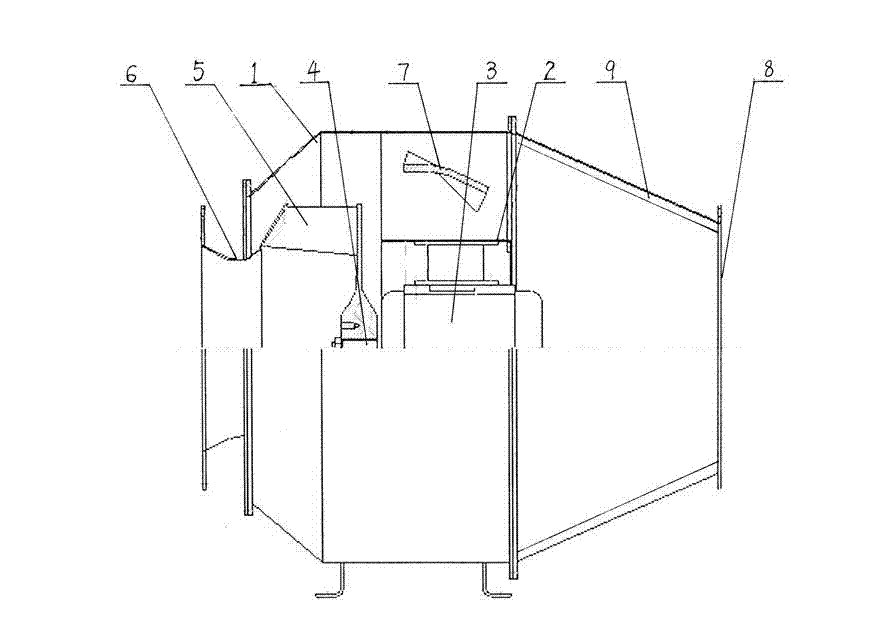

[0013] figure 1 As shown, a marine explosion-proof mixed flow fan includes an outer cylinder body 1, an inner cylinder body 2, an axial flow motor 3, a centrifugal impeller 5, an air inlet 6, a rear guide vane 7 and an air outlet 8. The centrifugal impeller 5 is installed on the motor shaft 4 of the axial flow motor 3. The axial flow motor 3 is installed in the inner cylinder 2. The inner cylinder 2 is connected to the outer cylinder 1 via the rear guide vane 7, and the rear guide vane 7 is a twisted blade type. The air inlet 6 and the centrifugal impeller 5 are matched and installed at one end of the outer cylinder 1. The air inlet 6 is an arc cylinder with openings at both ends larger than the diameter of the middle part. The outer cylinder at the outlet of the centrifugal impeller 5 is Open outwards, the centrifugal impeller 5 is a cast aluminum alloy cast airfoil....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com