Device and method for detecting sealing quality and gas-leakage position of coal seam gas extraction drill-hole

A technique for extracting boreholes and coal seam gas, which is applied in construction and other fields, and can solve the problems of undrained borehole sealing quality and gas leakage position detection and analysis, complicated hole sealing process, lack of coal seam gas, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

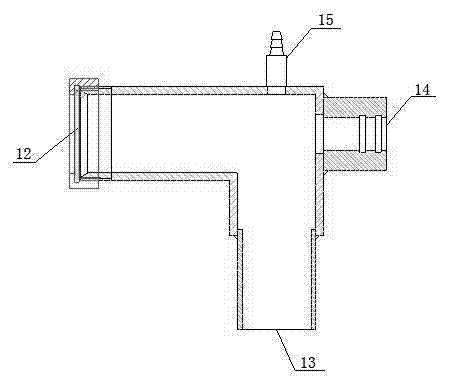

[0017] Depend on figure 1 and figure 2 The shown is a detection device for the sealing quality of coal seam gas drainage boreholes and the position of gas leakage, including a quick-connect tee 6 with three connection ports, a detection pipe 3 and a gas analyzer 11 connected to the detection pipe 3. The connection tee 6 is also provided with a sampling and measuring port 15 . The three connection ports of the quick-connect tee 6 are: a first connection port 12 , a second connection port 13 and a third connection port 14 . The detection tube 3 is a hard hose 7 , and the detection tube 3 is coiled on the reel 10 . The gas analyzer 11 has a built-in micro-vacuum pump, gas concentration detection element, pressure detection element, and temperature detection element for collecting and analyzing the gas concentration and extraction negative pressure at a predetermined depth in the extraction borehole 2 . The gas analyzer 11 is a prior art, so it will not be described in detail....

Embodiment 2

[0019] Depend on figure 1 and figure 2 A method for detecting the sealing quality of coal seam gas drainage boreholes and the location of gas leakage is shown, which includes the following steps: (1) Construction of a drainage borehole 2 in a coal seam 1, after the construction is completed, in the drainage borehole 2 Put it into the extraction pipe 4, then grout and seal the hole, seal the gap between the extraction pipe 4 and the extraction borehole 2 with the sealing material 5, the drainage pipeline 9 is provided with an on-off valve 8, and the coal seam 1 is drilled The drainage pipe 4 in 2 is connected to the on-off valve 8 of the drainage pipeline 9 through the connecting pipe, and the drainage pipe 4 is connected to the drainage pipeline 9 to start gas extraction;

[0020] (2) When it is found that the gas concentration at the orifice of the drainage borehole 2 is low and the sealing quality of the drainage borehole 2 needs to be tested, it is necessary to use the se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com