Prefabricated tubular pile with end screw thread with X-shaped variable section and construction method thereof

A prefabricated pipe pile and thread technology, applied in sheet pile wall, foundation structure engineering, construction, etc., can solve problems such as reducing bearing capacity and large settlement, and achieve the effect of increasing bearing capacity, simple construction and high construction efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

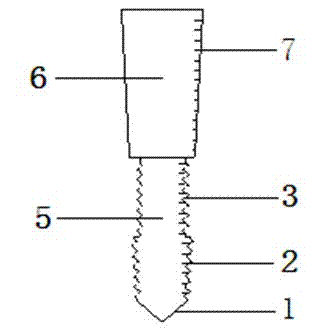

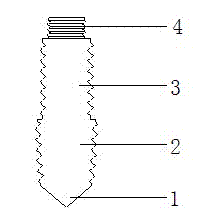

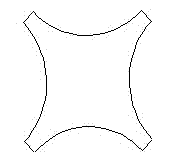

[0030] Embodiment 1: A kind of end threaded X-shaped deformed section prefabricated pipe pile provided by the present invention, its structure is as follows figure 1 As shown, it includes the first pipe section 5 and the second pipe section 6. The first pipe section 5 is provided with a pile point 1, a large section section 2, a small section section 3 and a top thread section from bottom to top. 4, such as figure 2 . The surface of large section section 2 and small section section 3 has threads, and the cross section is X-shaped, such as image 3 . The cross-section of the top threaded section 4 of the first pipe joint is circular.

[0031] The second pipe joint 6 is in the shape of an inverted truncated cone, such as Figure 4 , there is a through hole 9 in the center of the cone, and the lower part of the through hole is provided with an internal thread section 8. The surface of the cone is smooth, and a scale line 7 for observing the depth of the pile is set on the si...

Embodiment 2

[0032] Embodiment 2: Apply the construction method of a prefabricated pipe pile with an end threaded X-shaped cross-section provided in Embodiment 1 of the present invention, including the following construction steps:

[0033] (1) Level the site and put the pile driver 12 in place, such as Figure 5 shown;

[0034] (2) Lifting the first pipe section 5 of the prefabricated pipe pile with threaded X-deformed section at the end of the present invention: first fasten the steel wire rope and rigging used for hanging the pile, and then tie the rigging to the upper end of the first pipe section 5 Near the lifting ring, start the machine to lift the first pipe joint, so that the pile point 1 is vertically aligned with the center of the pile position. After the position is accurate, it is slowly lowered and inserted into the soil, and then the pile cap 10 or pile collar is fastened on the top of the first pipe joint. The rigging can be removed;

[0035] (3) Stabilized pipe pile: Aft...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com