Novel construction method of precast slab assembled floating road bed

A technology of floating ballast bed and construction method, which is applied in the direction of roads, tracks, ballast layers, etc., can solve the problem that the side-mounted vibration isolator and the inner sleeve of the vibration isolator cannot be uniformly stressed, and the side-mounted Problems such as damage to the inner sleeve of the vibrator, unfavorable track structure and train operation, etc., achieve the effects of convenient splicing, shortened construction period, and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0064] Such as figure 1 As shown, the construction method of the prefabricated slab-assembled floating ballast bed of the present invention comprises the following steps:

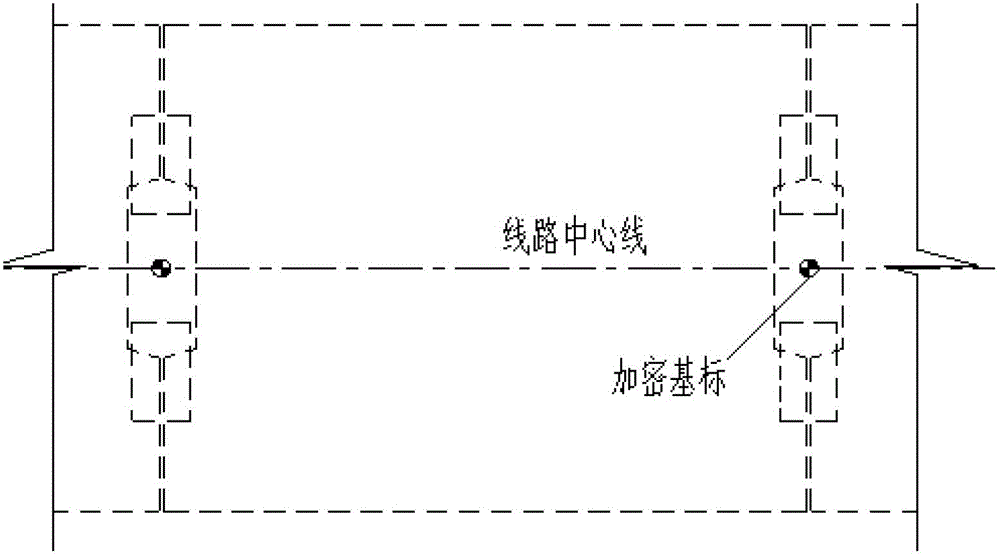

[0065] 1) Lay out the line center line of the floating ballast bed base and the encrypted base mark for positioning the multiple floating ballast bed prefabricated slabs to be laid;

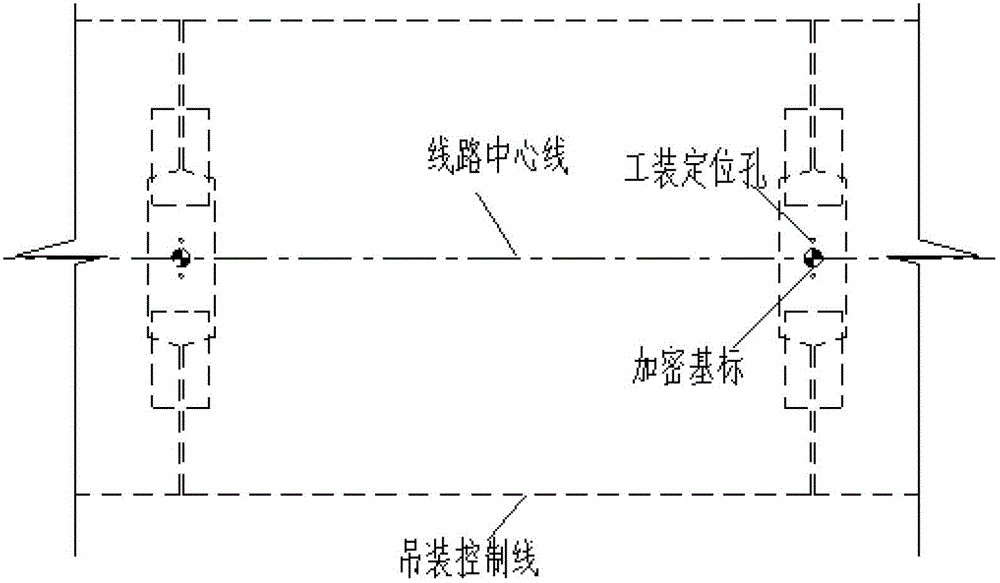

[0066] 2) Lay out the hoisting control line of each prefabricated slab of the floating ballast bed and the tooling positioning holes for its auxiliary positioning;

[0067] 3) Install auxiliary tooling according to the positioning holes of the tooling, and install a plurality of floating ballast bed prefabricated panels on the floating ballast bed base in sequence according to the auxiliary tooling and the hoisting control line, and accurately adjust each prefabricated panel After that, it is connected to form an integrated floating track bed;

[0068] 4) Install the inner sleeve of the vibration isolator in each prefabricat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com