Transformer oil and preparation method thereof

A technology of transformer oil and silicone oil, applied in the field of lubricating oil, can solve the problems of no silicone oil transformer oil, no silicone oil transformer oil research report, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

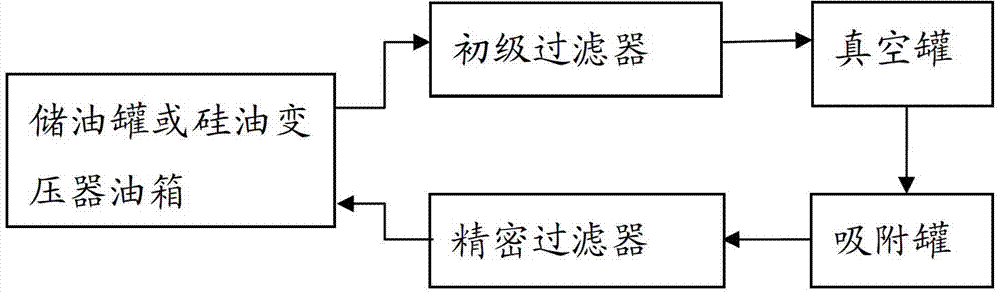

Image

Examples

Embodiment Construction

[0031] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with the examples, but it should be understood that these descriptions are only for further illustrating the features and advantages of the present invention rather than limiting the patent requirements of the present invention.

[0032] Example of acid polymerization process

[0033] Reaction materials and specifications:

[0034] (1) Dimethyldichlorosilane hydrolyzate, kinematic viscosity at 25°C 5-20mm 2 / s

[0035] (2) Hexamethyldisiloxane, boiling range 99~102℃

[0036] catalyst:

[0037] Concentrated sulfuric acid, concentration ≥ 95%

[0038] Material ratio:

[0039] The mass ratio of hexamethyldisiloxane to dimethyldichlorosilane hydrolyzate is 2-8%, preferably 4-6%; the amount of catalyst added is 2-10% of the total reactants, preferably 4-8% %.

[0040] Polymerization reaction temperature: 10-60°C, preferably 20-50°...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com