Graphene-copper nanoparticle composite, and preparation and application thereof

A composite material, copper nanotechnology, applied in the fields of material electrochemical variables, electrolytic coatings, chemical instruments and methods, etc., can solve the problems of difficult mass production, difficult to control the degree of reduction, and superior performance discounts, and achieve simple operation. , Reduce the effect of graphene specific surface reduction and fast experimental operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] 1. Preparation of Graphene Oxide Solution

[0037] The graphite oxide prepared by the Hummers oxidation method was ultrasonically dispersed in a buffer solution with pH=9.18 for 3 hours to obtain a graphene oxide solution with a concentration of 0.3 g / L.

[0038] 2. Preparation of EDTA-Cu solution

[0039] Combine 0.2M EDTA solution and 0.2M CuSO 4 Mix 1:1 to get the 0.1M EDAT-Cu solution we need

[0040] 3. Preparation of graphene and EDTA-Cu mixed solution

[0041] Measure 10 mL of the graphene oxide solution prepared in the first step, and then respectively weigh 100 μL, 500 μL, and 1000 μL of the EDTA-Cu prepared in the second step and mix them thoroughly, and then pass in high-purity nitrogen for 30 minutes.

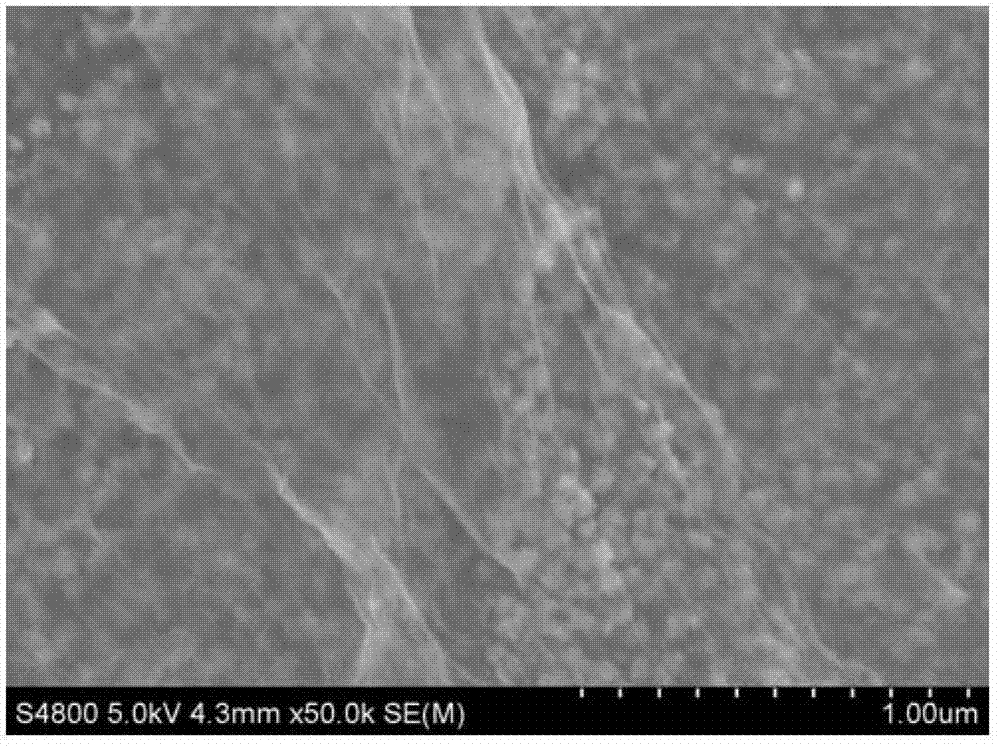

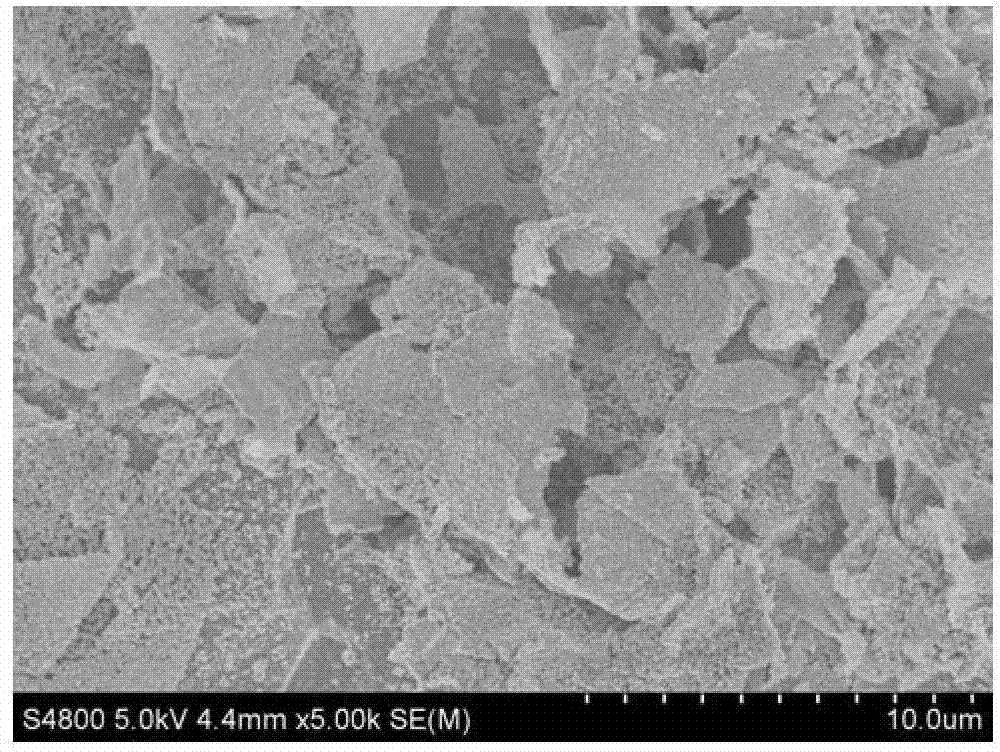

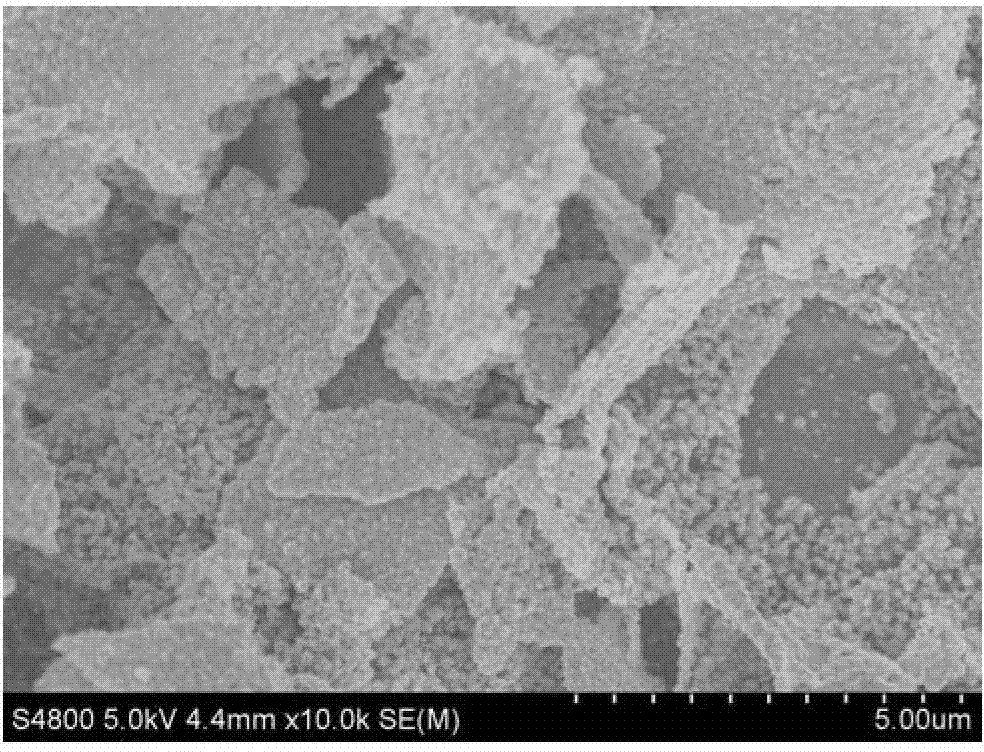

[0042] 4. Preparation of graphene-copper nanoparticle composites by electrodeposition

[0043] The glassy carbon electrode (or Ti sheet) is the working electrode (all processed in advance), the Pt electrode is the counter electrode, and the saturated calomel electrode is...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com