Hot-rolled strip steel rolling technology for preventing high-speed breaking-away of roughing mill

A technology for hot-rolled strip and roughing mills, applied in rolling mill control devices, metal rolling, manufacturing tools, etc., can solve problems such as large vibration and damage to equipment, and achieve the effect of reducing impact, ensuring normal production, and ensuring equipment is in good condition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below by embodiment.

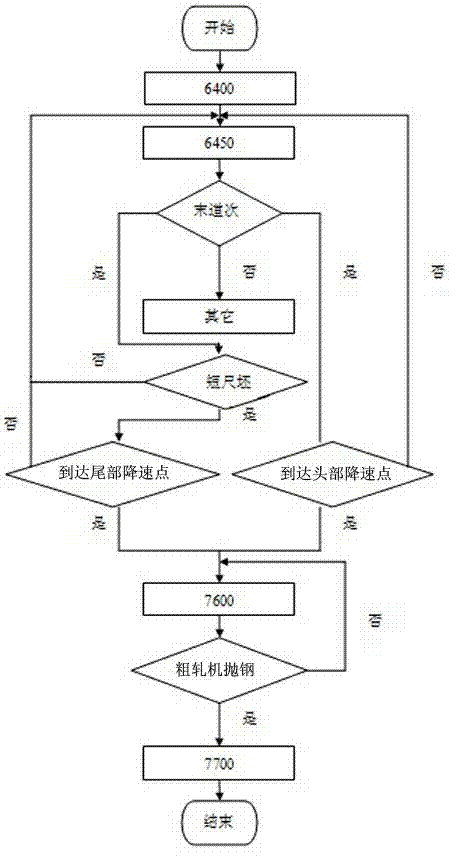

[0022] figure 1 Among them, 6400 is the rough rolling mill that bites steel at a biting speed of 2.8 m / s, 6450 is the rough rolling mill that rolls steel at the rolling speed (5.5 m / s at the last pass), and 7600 is the rough rolling mill that uses the hot coil box to thread the strip at a speed of 2.1 m / s Throwing steel in seconds, 7700 is steel at a creeping speed of 1.2 m / s after throwing steel in the rough rolling mill.

[0023] refer to figure 2 A rolling process for hot-rolled strip steel to prevent high-speed throwing of roughing mills, comprising heating, rough rolling, hot coiling, and finish rolling, with a detection point between heating and rough rolling, and the rolling process includes the following steps:

[0024] Step 1: Calculate the critical length S of whether the rough-rolled final slab is a short slab;

[0025] S=S 1 -S 2 +S 3 +k, where:

[0026] The distance S from the de...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com