A track drying device

A track and mounting hole technology, applied in cleaning methods and utensils, cleaning methods using tools, chemical instruments and methods, etc., can solve problems such as surface corrosion, achieve simple structure, fast automatic maintenance requirements, and improve the effect of maintenance quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

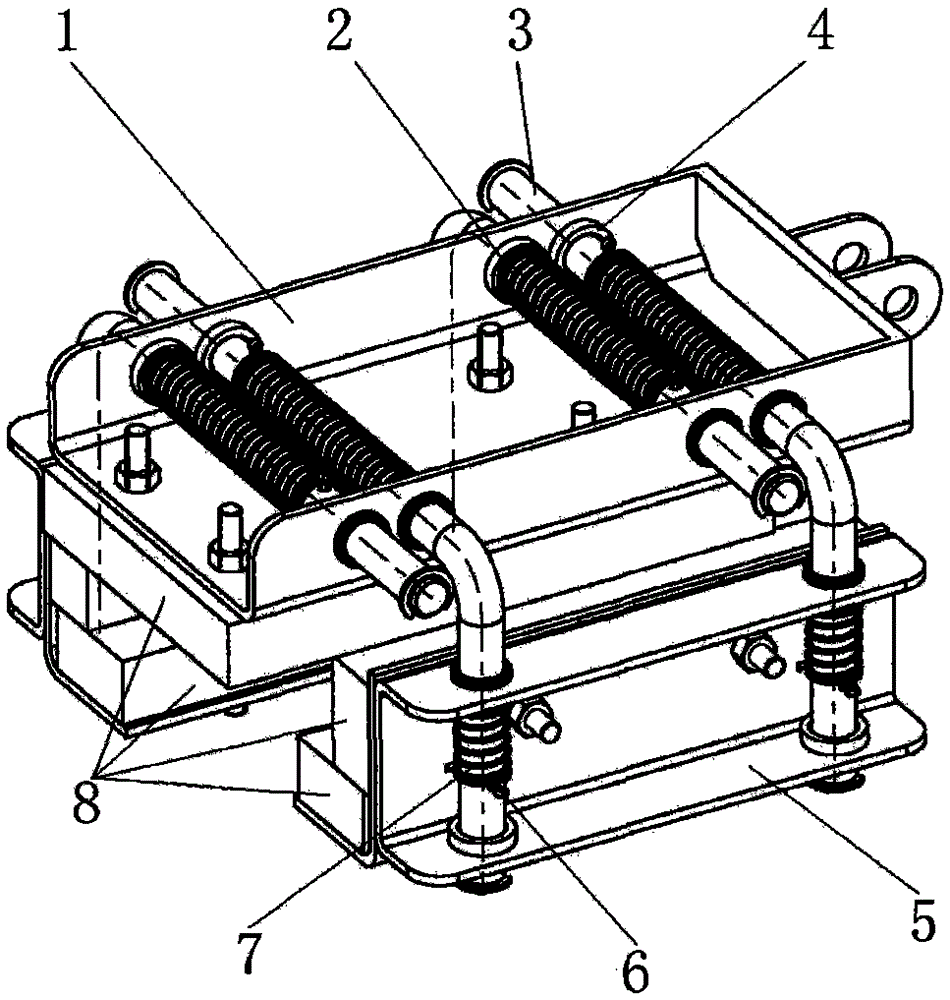

[0008] Such as figure 1 , 2 As shown, the track drying device of the present invention consists of an upper base 1 with baffle plates on both sides, an upper spring 2, an inverted L-shaped guide rod 3, a bearing 4, two side bases 5, a cotter pin 6, and a side spring 7 Composed of 8 dry ingredients. 5 pieces of drying material 8 are respectively fixed on the side surface and the bottom surface of the two side bases 5 and the upper base 1 by bolts or other means, and are in contact with the track; the two side bases 5 are respectively arranged on the upper Both sides of the base 1; the inverted L-shaped guide rod is composed of an integrally formed horizontal guide rod and a vertical guide rod,

[0009] The horizontal guide rod passes through the baffle plates on both sides of the upper base 1, and a bearing 4 is installed between the two to reduce friction; the upper spring 2 is installed on the horizontal guide rod between the baffle plates on both sides of the upper base 1,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com