Flotation method for re-cleaning lead zinc ore and sulfur concentrate after preferable mixing separating

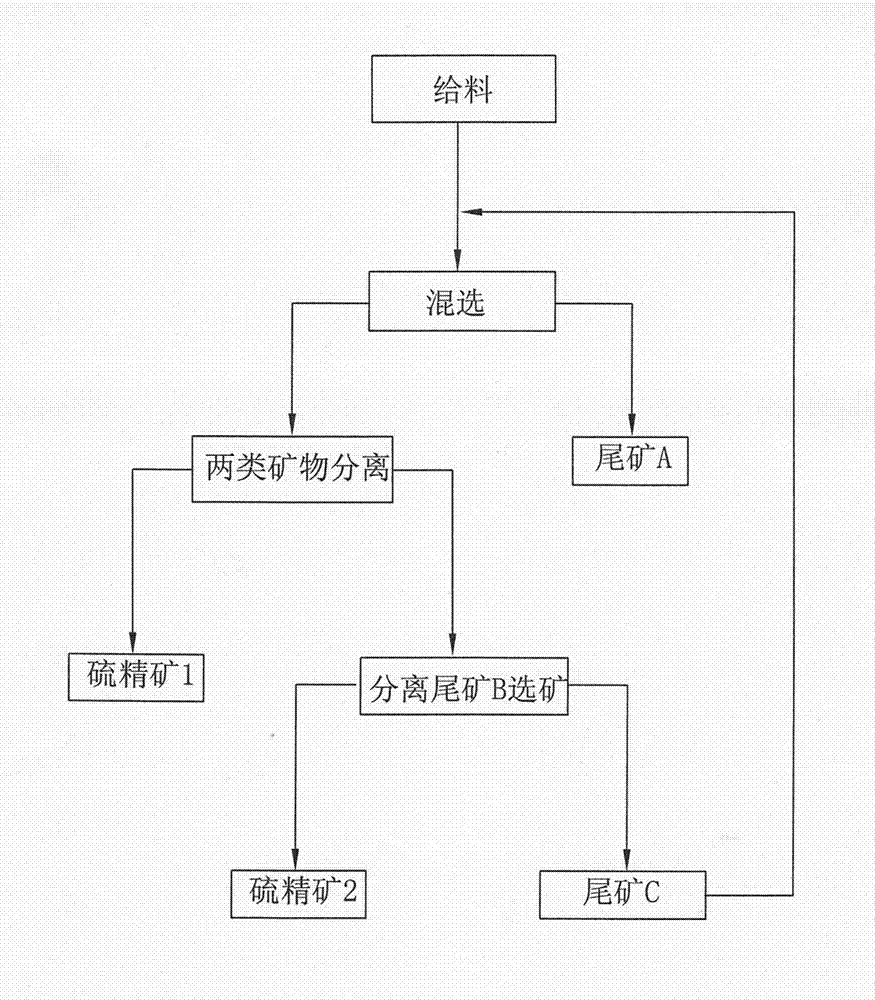

A technology of sulfur concentrate and lead-zinc ore, which is applied in flotation, chemical instruments and methods, wet separation, etc., can solve the problems that it is difficult to take into account the quality of the two concentrates at the same time, and the recovery rate is low, so as to save consumption, Effect of reducing loss and guaranteeing recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

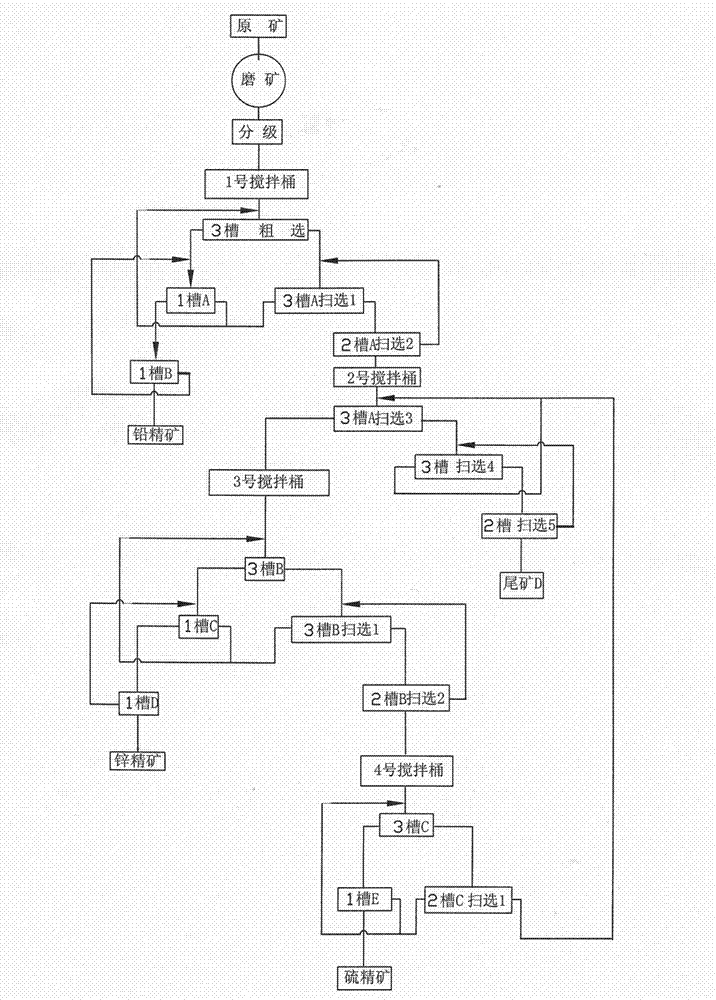

Embodiment 1

[0018] Embodiment one, as attached figure 2 As shown: the raw ore enters the No. 1 mixing tank after grinding and grading, the stirred raw ore enters the roughing of the third tank, the lead concentrate mixture produced by the roughing of the third tank enters the first tank A, and the other tailings produced by the roughing of the third tank Enter the 3rd tank A to sweep the 1st, the lead concentrate mixture produced in the 1st tank A enters the 1st tank B, the other tailings produced in the 1st tank A return to the 3rd tank for roughing, the lead concentrate produced in the 1st tank B becomes the lead concentrate product , the other tailings produced in tank 1 B return to tank 1, the zinc-sulfur concentrate mixture produced in tank 3 A sweeps 1 and enters tank 2 A to scan 2, and the other tailings produced in tank 3 A sweeps 1 and returns to tank 3 Groove roughing, other tailings produced by Sweeping 2 in 2nd trough A return to Sweeping 1 in 3rd trough A, the zinc-sulfur co...

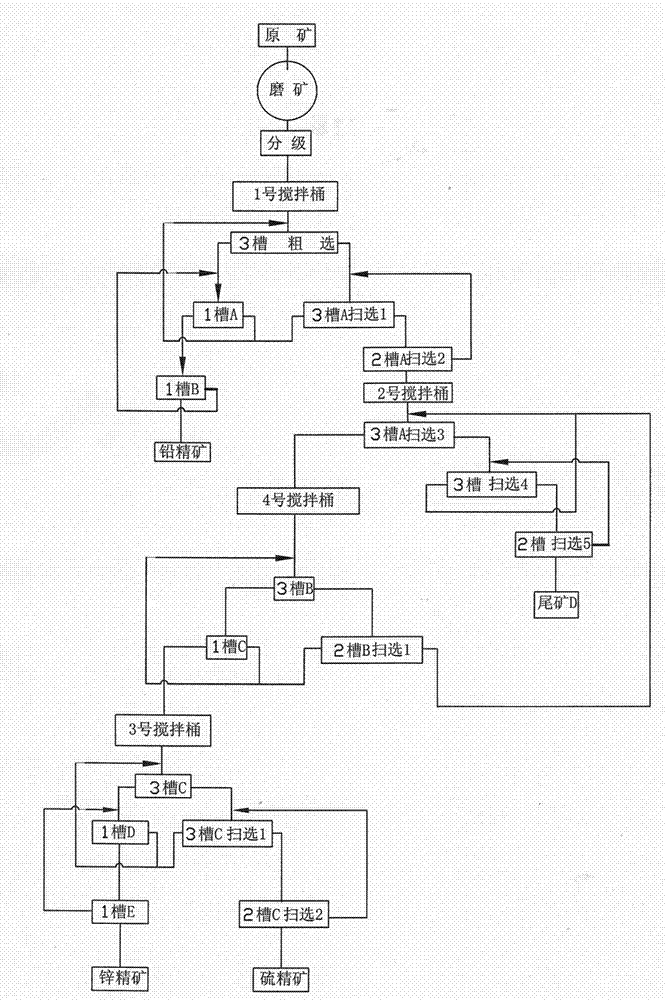

Embodiment 2

[0027] Embodiment two, as attached image 3 Shown: Before the selected ore enters the No. 2 mixing tank, it is the same as that in Example 1. After the zinc-sulfur concentrate mixture passes through the No. 2 mixing tank, it enters into the 3rd tank A to scavenge 3, and the 3rd tank A scavenges 3 to produce other tailings Enter into slot 3 for sweeping 4, the zinc-sulfur concentrate mixture produced in slot 3 for sweeping 4 returns to slot 3 for sweeping 3, other tailings produced in slot 3 for sweeping 4 enter slot 2 for sweeping 5, and slot 2 for sweeping 5 The zinc-sulfur concentrate mixture produced returns to scavenging 4 in tank 3, other minerals and gangues produced in tank 2 scavenging 5 form tailings D, and the zinc-sulfur concentrate mixture produced in scavenging 3 in tank A enters No. 4 stirring barrel, the zinc-sulfur concentrate mixture enters No. 4 mixing tank and then enters No. 3 tank B, the zinc-sulfur concentrate mixture produced in No. 3 tank B enters No. 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com