Complex catalyst for direct liquefaction of coal, and preparation method thereof

A technology of direct coal liquefaction and catalyst, which is applied in the direction of physical/chemical process catalysts, chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, etc., and can solve the problem of complex catalyst recovery process, high price, easy blockage, etc. problem, to achieve excellent catalytic effect, strong hydrogenation function, and easy to scale-up effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

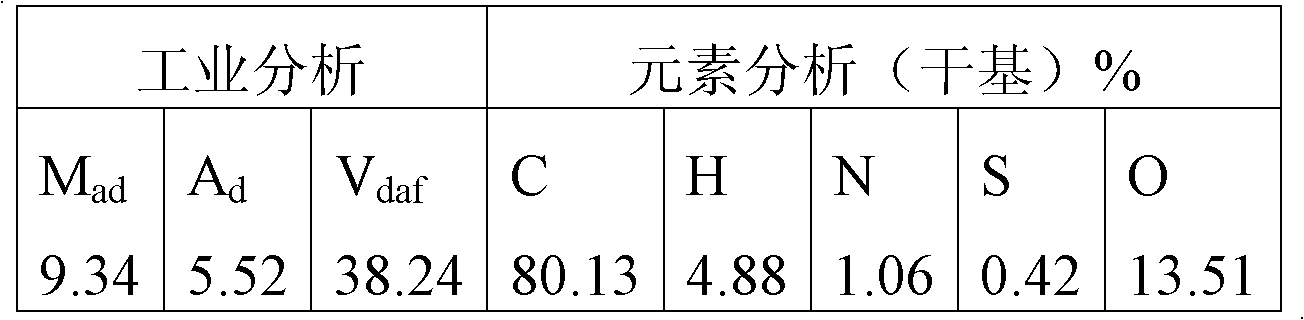

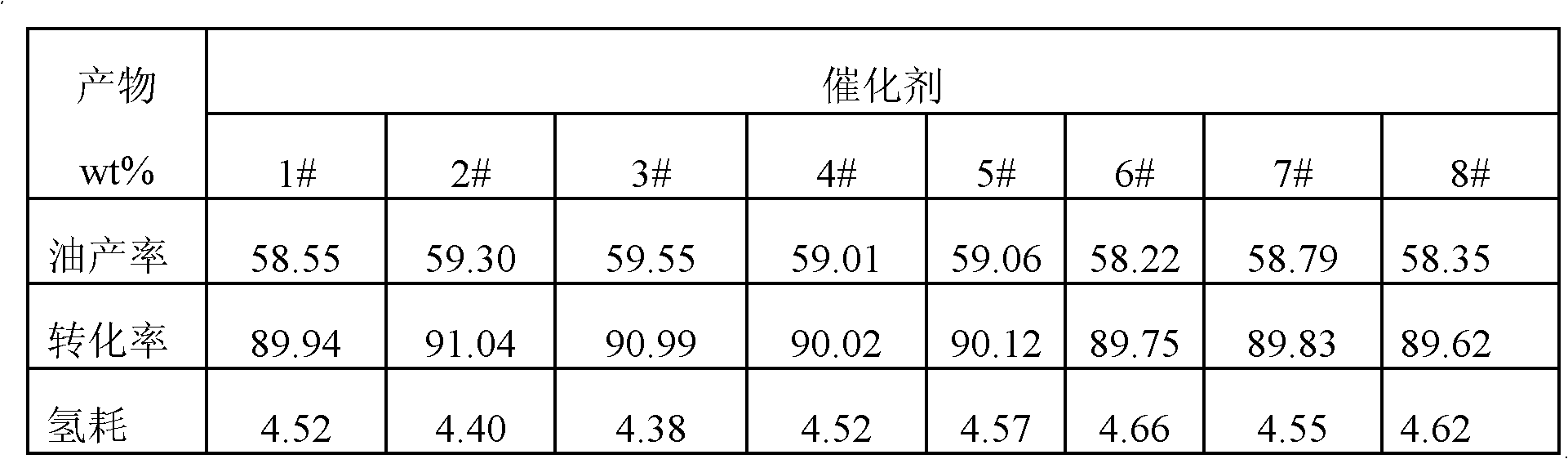

[0025] Take the natural laterite nickel ore from the Philippines, its iron content is 46%, and its nickel content is 0.87%. Impurities therein are removed, ground to 100 mesh (150 μm), vacuum dried for 3 hours, and directly used as a catalyst for direct coal liquefaction (set as 1# Catalyst, mass ratio Fe:Ni=100:1.9).

Embodiment 2

[0027] Take the natural laterite nickel ore from Indonesia, its iron content is 49%, and its nickel content is 2.45%. Impurities therein are removed, ground to 150 mesh (112 μm), vacuum dried for 3 hours, and directly used as a catalyst for direct coal liquefaction (set as 2# Catalyst, mass ratio Fe:Ni=100:5).

Embodiment 3

[0029] Take the natural laterite nickel ore from Myanmar, its iron content is 48%, and its nickel content is 1.7%. Impurities therein are removed, ground to 200 mesh (74 μm), vacuum dried for 3 hours, and directly used as a catalyst for direct coal liquefaction (set as 3# Catalyst, mass ratio Fe:Ni=100:3.6).

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com