Protective energy-saving cover for high-pressure cookers

A technology of pressure cooker and energy-saving cover, applied in the direction of pressure cooker, cooker shell/sleeve, etc., can solve the problems of easy to be scalded or scalded, large exposed area of metal surface, unfavorable heat preservation, etc., to reduce the chance of scalding or scalding , good energy saving and thermal insulation effect, reducing the effect of scalding pain or scalding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

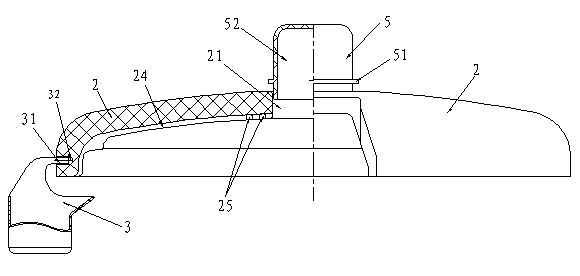

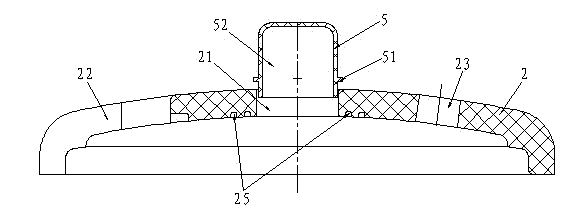

[0025] Cooking high -pressure cooker protective energy -saving cover for the implementation of the present invention (see Figure 1-Figure 6 ) The structure is characterized by: including the insulation cover 2 on the outer surface of the pot lid 1 on the high -pressure pot lid;Success; The valve position 21 for avoiding pressure limit valve caps on the thermal cover 2, between the valve position 21 and the weekly side of the valve cap and the valve cap with a suitable vowel gap to make it from the valve cap 11The sprayed vapor can be discharged from the gap; the heat insulation cover 2 is used to avoid the handle of the cover handle 13.

[0026] According to the specific structure on the pot lid 1, the thermal insulation cover 2 has a safety hole 23 used to avoid safety valve 14, so that the effect of safety valve 14 is not affected;The seat slot of other safety components on 1, so that the thermal insulation cover 2 can be set and used safely on the pot lid 1.

[0027] The valve ...

Embodiment 2

[0042] Example 2 of the present invention 2 cooking high -pressure cooker protective energy -saving cover (see see seeking Figure 7-Figure 9 To.In order to make the function of the protective energy -saving cover of the present invention more perfect, so that it is easier to implement and apply. On the basis of the Example One of the invention, the Example II of the present invention further constructs the following structure, and its benefits are subsequently expressed.

[0043] The above side of the thermal insulation cover 2 has a shell 4 made of plastic material made of suitable intensity with a suitable intensity.The shell film 4 is conducive to protecting the thermal insulation cover 2, which is the same as the surface of the heat heating cover of the foam plastic material 2 that is easily contaminated and easy to deform and damage, so that the thermal heating cover 2It is better to adapt to the requirements of the energy -saving cover of the present invention to actively us...

Embodiment 3

[0045] Example III of the present invention 3 Cooking high -pressure cooker protective energy -saving cover (see see seeking Figure 10-Figure 12 To.In order to make the function of the protective energy -saving cover of the present invention more perfect, so that it is easier to implement and apply. On the basis of the Example One of the invention, the Example II of the present invention further constructs the following structure, and its benefits are subsequently expressed.

[0046] Further constructing 1: The above -mentioned insulation hood 2 has a hood shell 6 that is nested with it; the hood shell 6 is equipped with the corresponding valve cap hole of the valve cap 11 and the avoided pot lid 1 1The position of other safety components.

[0047] The hooded shell 6 is conducive to protecting the thermal insulation cover 2, which is easy to be contaminated by the heating cover of the foam plastic material.It is better to adapt to the requirements of the energy -saving cover of th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com