Annular spring elastic cushion and manufacturing method thereof

The technology of a ring spring and its manufacturing method is applied in the direction of spring mattresses, mattresses, stuffed cushions, etc. It can solve the problems of large deformation, inability to give full play to the comfort of elastic cushions, and hard springs, and achieve controllable thickness and elasticity. Convenient and reliable adjustment, good ventilation performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

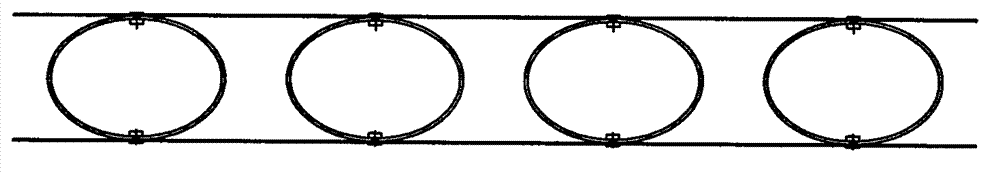

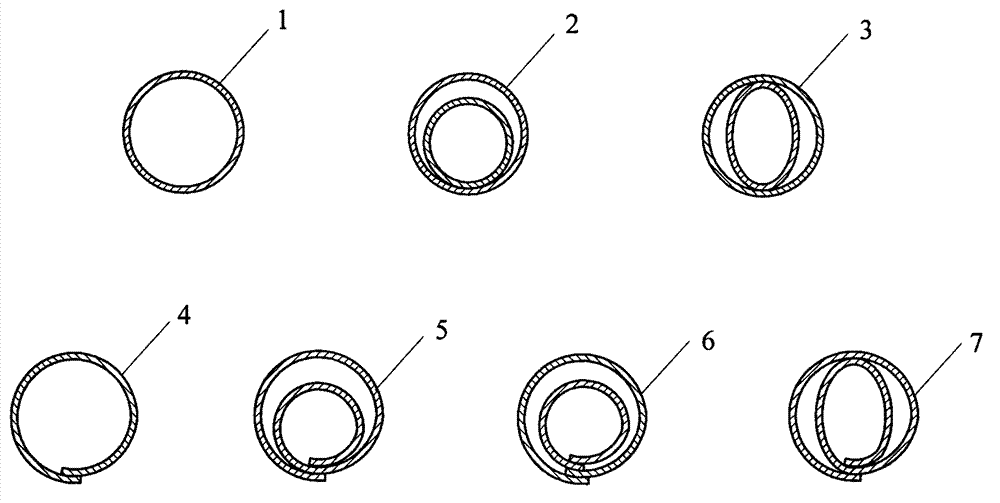

[0025] Embodiment 1: This embodiment is a method for making elastic pads with closed ring springs arranged in parallel.

[0026] Refer to attached Figure 4 And attached figure 1 It can be seen that the basic components of the elastic pad are ring springs, connecting pieces, and fixed connectors.

[0027] Manufacturing method is as follows: (1) circular spring perforation is 50 millimeters in diameter, and width 15 millimeters, on the circumference of the elastic annulus of wall thickness 0.8 millimeters each punches the perforation of diameter 3 millimeters in the opposite side middle part of 180 degree included angle mutually, Drilling or punching can be used for drilling, and it is required to remove the burrs around the hole; (2) The connection piece is drilled with a thickness of 0.5 mm, a width of 15 mm, and a length greater than the length or width of the support pad. A series of perforations with a diameter of 3 mm are punched 60 mm apart, and the holes are required ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com