Magnet roller

A magnetic roller and magnetic force technology, applied in the direction of magnets, magnetic objects, permanent magnets, etc., can solve the problem of limited range of resin selection, and achieve the effects of excellent reusability, simple manufacturing process and good environment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 Embodiment approach

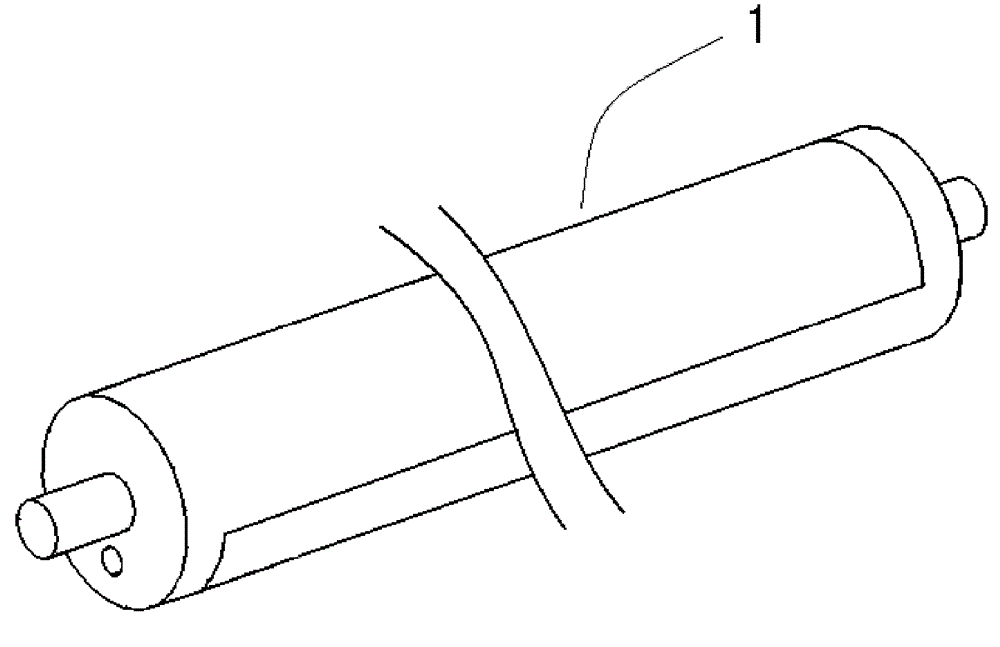

[0055] Such as figure 1 As shown, the magnet roller 1 according to the first embodiment of the present invention is composed of a single metal shaft member 4 and a pair of first and second semicylindrical resin magnet members 2 and 3 shorter than the metal shaft member 4 . Such as image 3 , Figure 5 As shown, the semi-cylindrical resin magnet parts 2 and 3 have the same shape and size as each other, and are respectively formed by injection molding into elongated split cylinders. On each end of these parts 2 and 3, a 1st and 2nd annular part 20,30. First and second center holes 21 and 31 are respectively penetratingly provided at the centers of these annular parts 20 and 30 . Such as image 3 As shown, a semicircular cavity 22 is formed inside the semicylindrical resin magnet part 20 . Although not shown, semicircular cavities having the same shape and size are also formed in the semicylindrical resin magnet member 30 . The first and second center holes 21 and 31 commun...

no. 2 Embodiment approach

[0068] A magnet roller according to a second embodiment of the present invention will be described. Such as Figure 11 As shown, the magnetic roller 5 of the second embodiment of the present invention is the same as the magnetic roller of the first embodiment of the present invention described above, and consists of a pair of first and second semicylindrical resin magnet members 6, 7 and a single metal shaft member. 8 composition. And assembled by a pair of semi-cylindrical resin magnet parts 6, 7 sandwich the metal shaft part 8, the three parts are fitted together and integrated, the support parts 81 at both ends of the metal shaft part 8 protrude from the circle of the resin magnet part. Tubular roller.

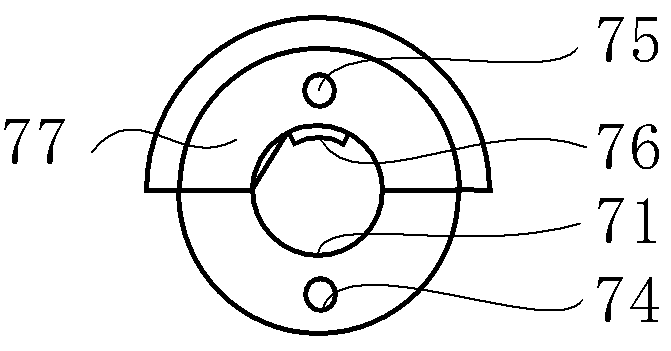

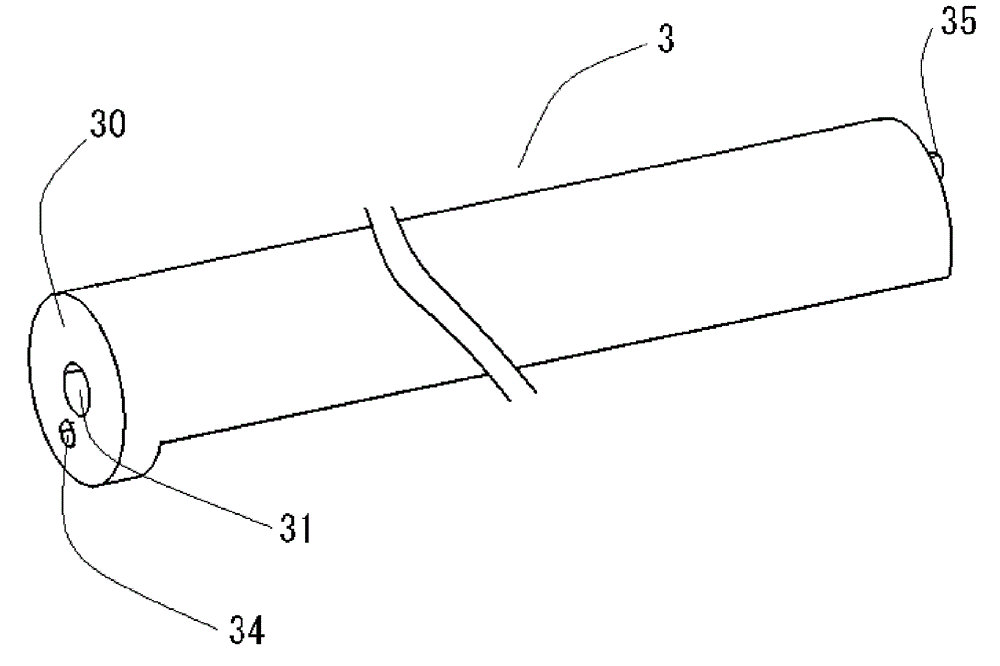

[0069] On a pair of semi-cylindrical resin magnet parts 6, 7, such as Figure 12 , Figure 14 , Figure 16 , Figure 18 As shown, the first and second annular portions 60 and 70 are integrally provided at one end portion of each of the elongated split cylinders. The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com