Oblique scan display method in direct writing photoetching system

A lithography system and oblique scanning technology, which is applied in the field of oblique scanning display in direct-write lithography systems, can solve the problems of reducing image resolution and minimum line width, and achieve the effect of optimizing working mode and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The invention is a method for obliquely scanning and displaying images in a direct writing photolithography system.

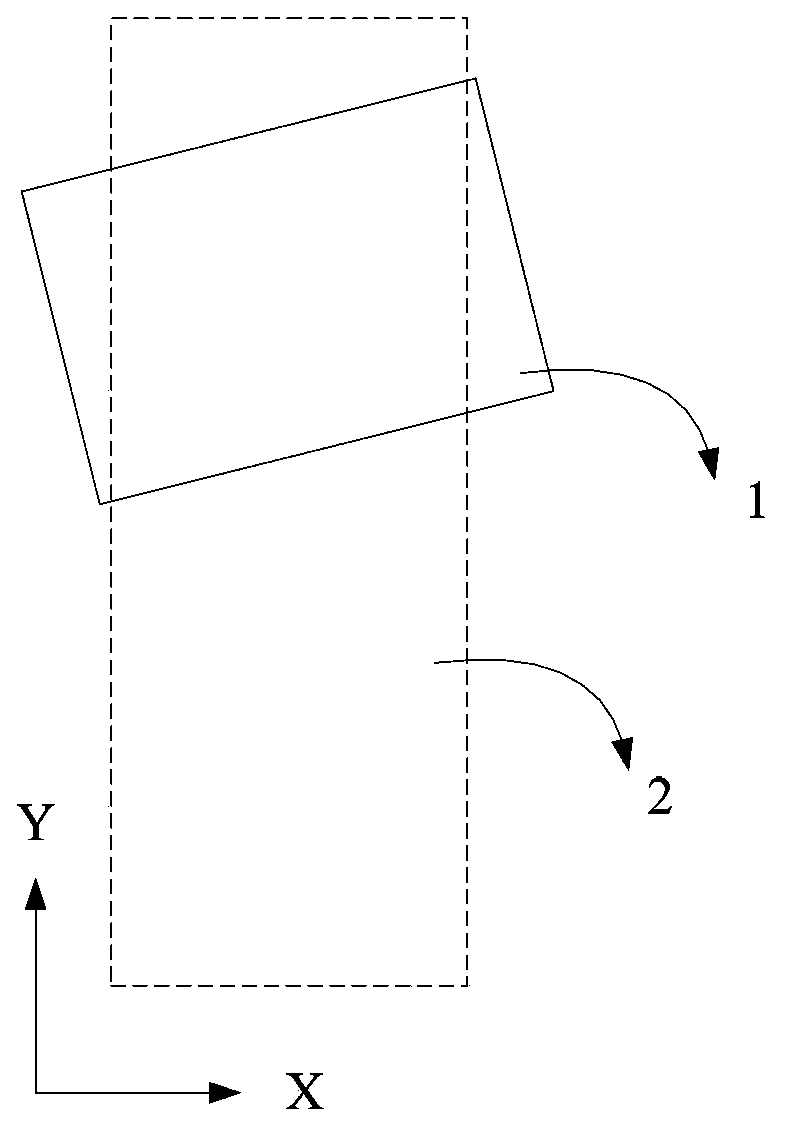

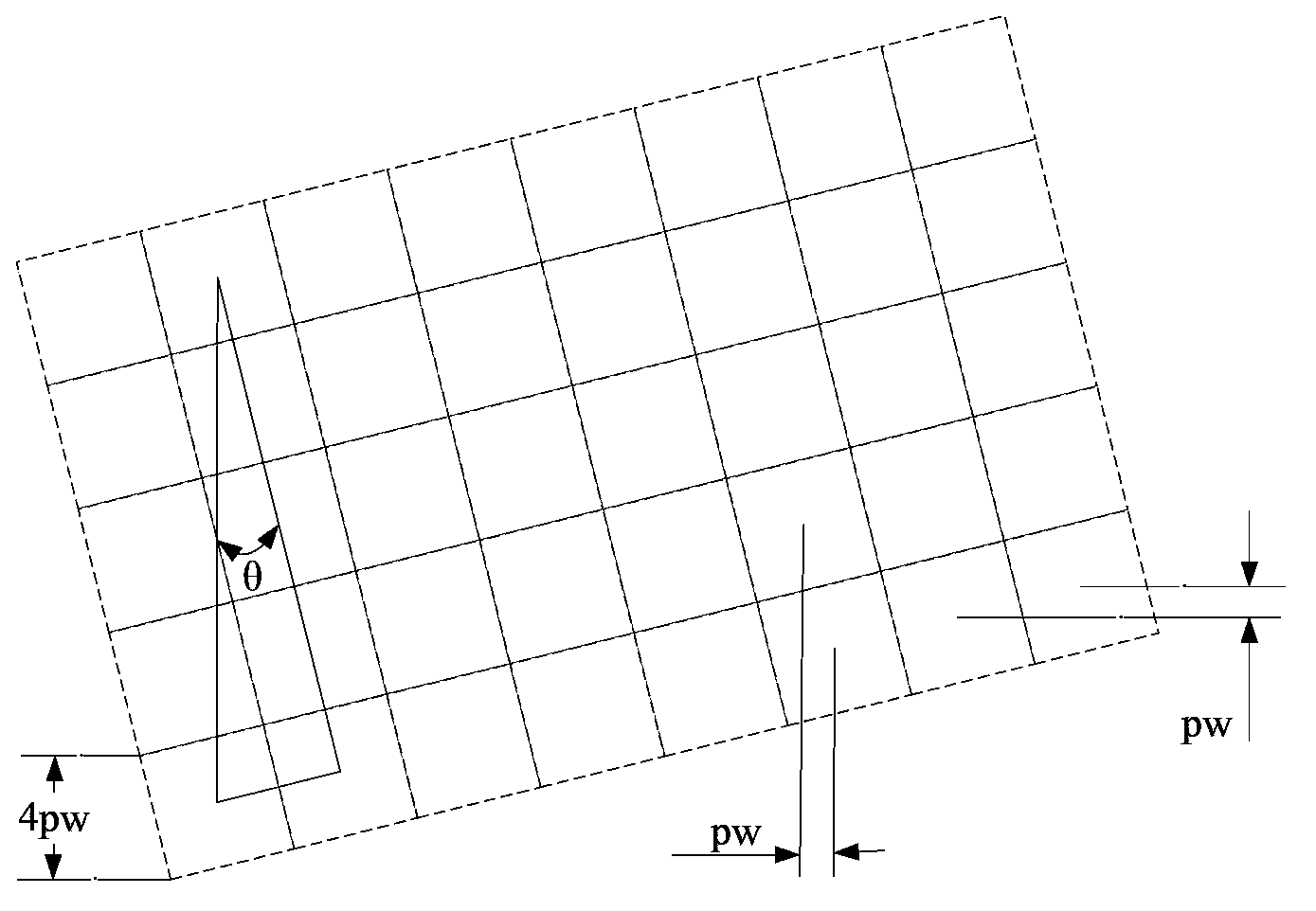

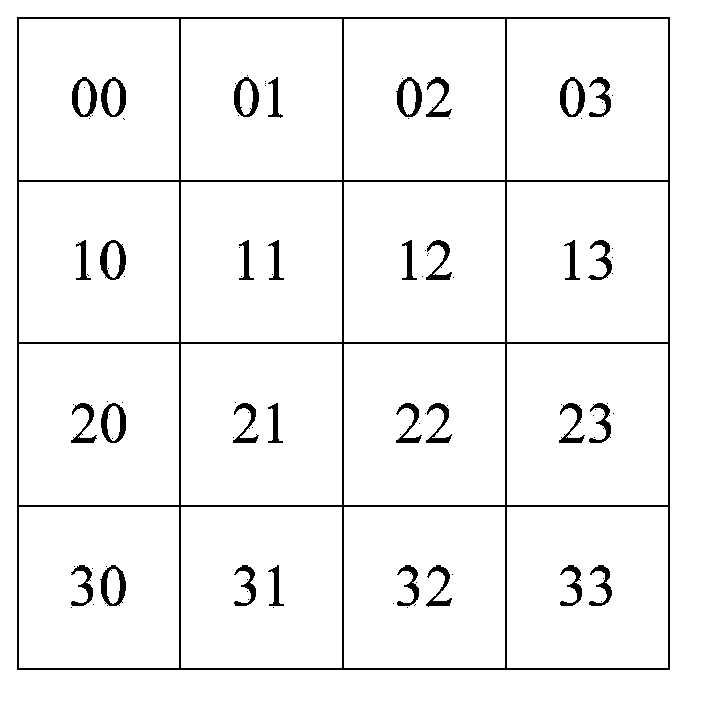

[0025] refer to figure 1 , figure 2 , the micromirror DMD1 of the present invention is fixedly installed with an inclination, the micromirror DMD1 rotates 14.0362 ° counterclockwise when the tilt factor N=4, and the micromirror DMD1 rotates 7.125 ° counterclockwise when the tilt factor N=8, selects the tilt factor N= in the present embodiment 4; The exposure surface is sucked on the platform 2 and can move back and forth in the Y direction. exist figure 2 The figure shows the 5×8 partial diagram of the micromirror DMD1 installed obliquely. It can be seen from the figure that when the tilt factor N=4, the rotation angle θ=14.0362°. Assuming that the length and width of a projected pixel are respectively pl, it can be Calculate pw=pl×0.24254, the centers of two columns of pixels connected by the tilted micromirror DMD1 are 4pw in X direction and 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com