Test system for simulating pore-fissure double-medium seepage hydraulic characteristics

A technology of porous medium and test system, which is applied in the field of test system for simulating the seepage hydraulic properties of pore-fracture dual medium

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] Below in conjunction with accompanying drawing, the present invention is described in detail:

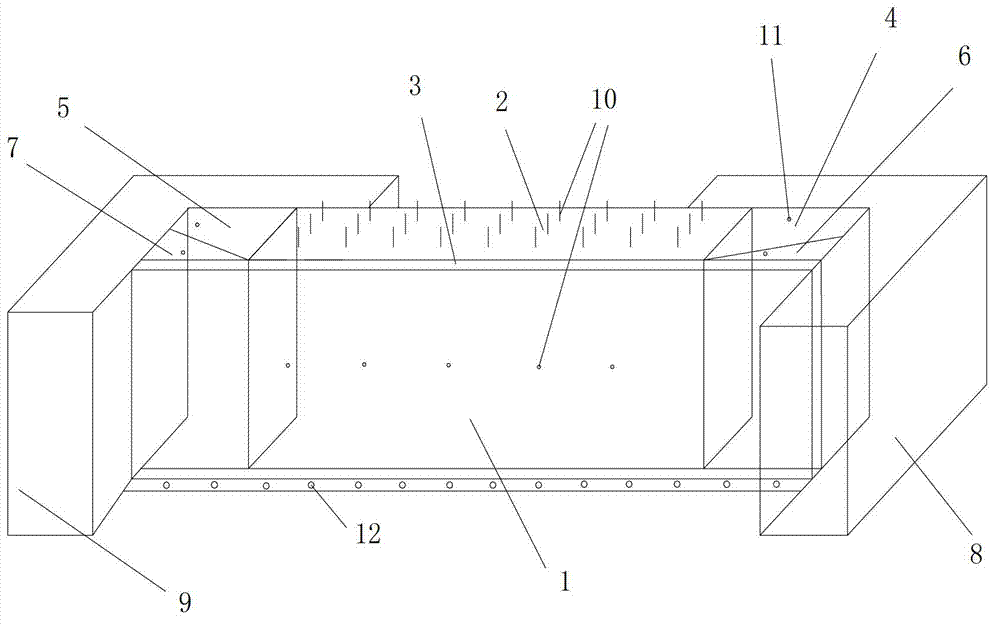

[0034] 1) Production of medium test module: such as figure 1 As shown, the medium test module is directly poured on the test bench 16. Before pouring, a layer of 3 cm thick plain concrete mixed with silicone waterproofing agent is filled at the bottom of the bamboo plywood mold to simulate the impermeable bottom boundary of the porous medium. When pouring porous concrete, the stainless steel pressure measuring tube 10 is pre-embedded to measure the water pressure. The cracked medium is made of smooth plexiglass plate side walls 13 and porous concrete. The size of the side wall 13 of the plexiglass plate is length×width×height=1700mm×300mm×500mm. There is a base 14 with a width of 50 mm at the bottom of the side wall 13 of the plexiglass plate, and a slide groove 15 is arranged on the base 14 to facilitate the adjustment of the width of the crack. The side wall 13 of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com