Concealed hinges for furniture

A technology for concealed hinges and furniture, applied in the field of hinges, can solve the problems of wear between torsion springs and parts, strong contact pressure, affecting the life of torsion spring hinges, etc., to reduce rigid friction, reduce pressure, and open and close smoothly and reliably.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

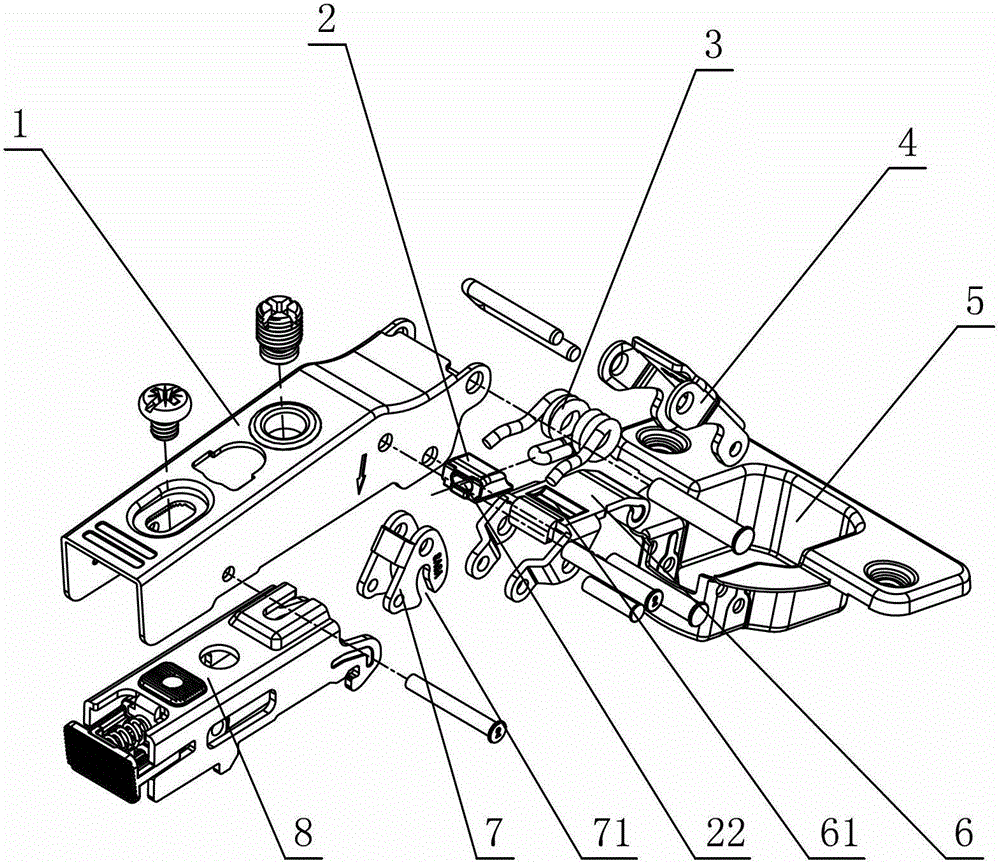

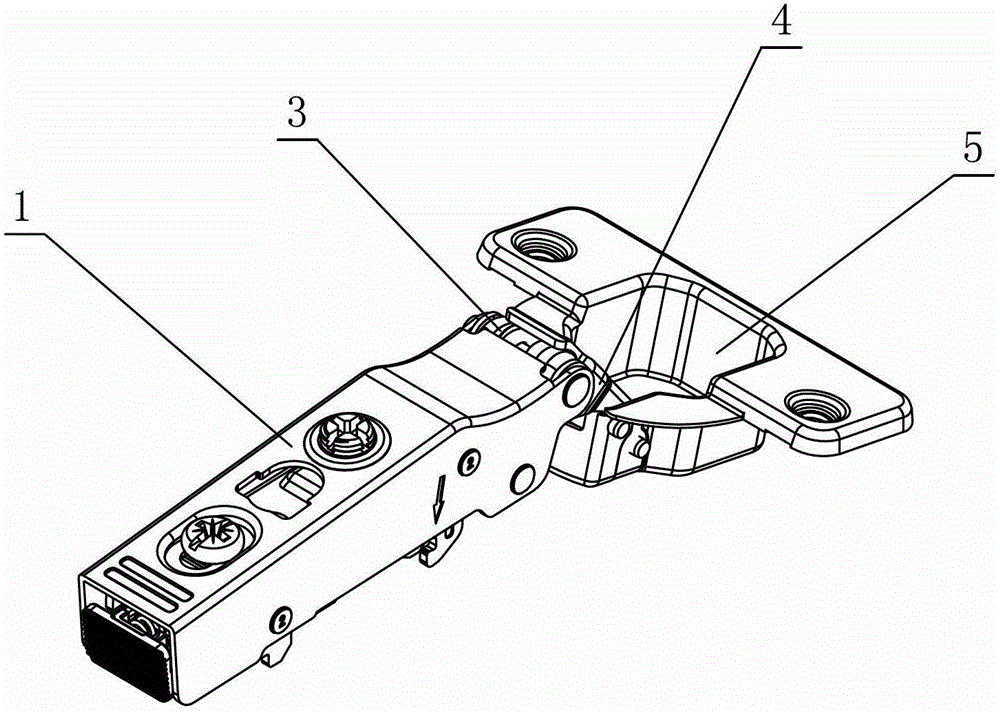

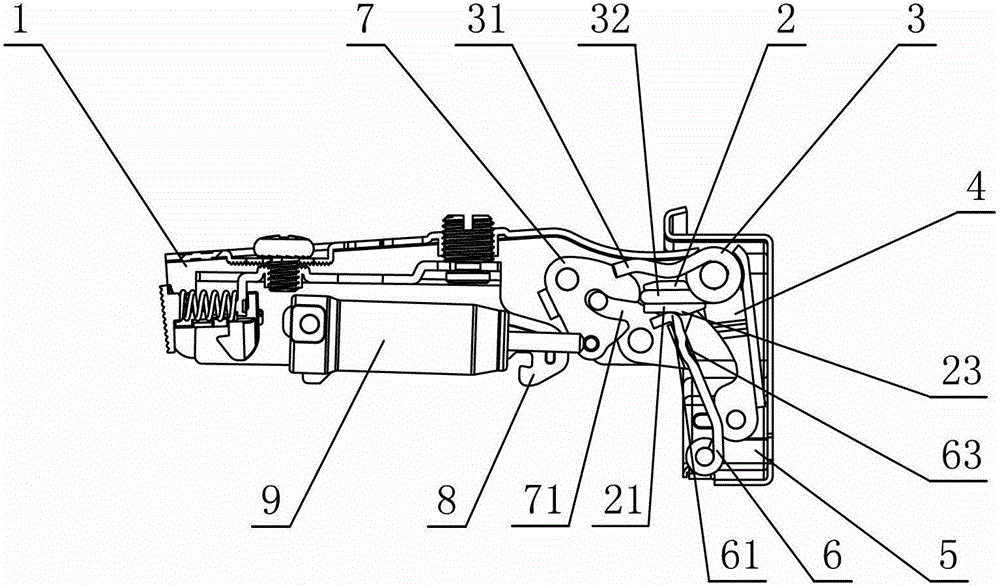

[0036] see figure 1 - Figure 6 , the concealed hinge used for this furniture, including the connecting arm 1 and the movable cup holder 5 connected by the swing arm assembly, the hinge is provided with a torsion spring 3 that at least generates an opening and closing force on the movable cup holder 5, and the torsion spring 3 has at least one supporting foot The positioning block 2 is provided with a sliding connection with the swing arm; the positioning block 2 is provided with a contact surface 21, and the contact surface 21 is slidingly connected with the swing arm in the opening and closing process of the hinge; Part of the limit is fixed on a supporting foot and / or swing arm of the torsion spring 3.

[0037] The components of the hinge are combined as follows: the swing arm assembly includes the outer swing arm 4 and the inner swing arm 6; the two ends of the outer and inner swing arms are respectively hinged with the connecting arm 1 and the movable cup holder 5; , th...

no. 2 example

[0042] see Figure 7 One end of the contact surface 21 of the positioning block 2 is provided with a groove 24, and the inner swing arm 6 is provided with a boss B64 corresponding to the groove 24 to cooperate with its concave and convex, so that the positioning block 2 is limited and fixed on the inner swing arm 6. Other unmentioned parts are the same as the first embodiment.

no. 3 example

[0044] see Figure 8 , the inner wall of the sleeve hole 22 of the positioning block 2 is provided with a protrusion 25 , and the positioning block 2 is limited and fixed on the middle support leg 32 of the torsion spring 3 through the protrusion 25 . Other unmentioned parts are the same as the first embodiment.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com