High-elongation fiber concrete combined frame filled wall and construction method thereof

A fiber-reinforced concrete and filling wall technology, which is applied to walls, building components, and earthquake resistance, can solve problems such as poor wall deformation, casualty economy, and filling wall damage, so as to improve seismic performance, improve integrity and seismic performance , Enhance the effect of seismic performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

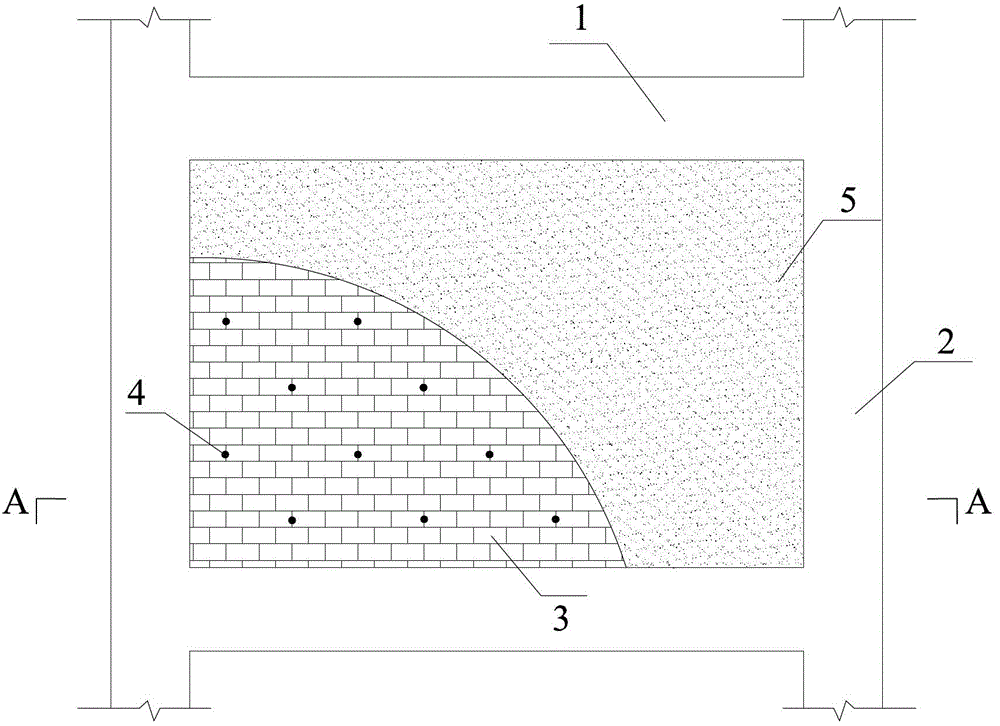

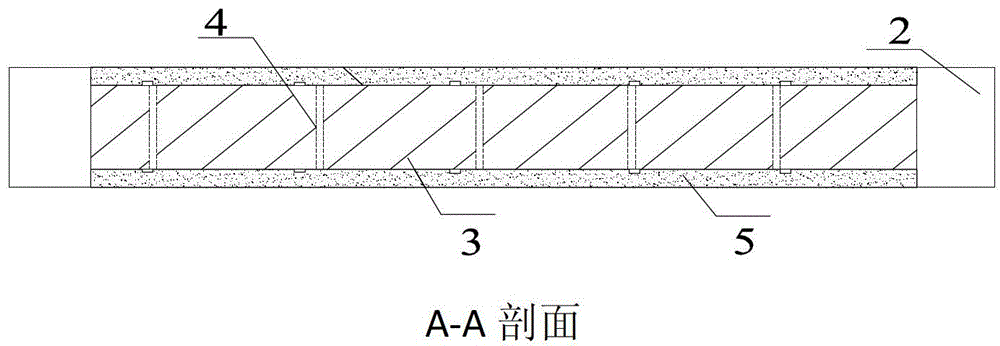

[0026] refer to figure 1 and figure 2 , The dimensions of the high ductility fiber concrete composite frame filled wall in this embodiment are as follows: the length is 4.2m, the height is 3m, and the thickness is 240mm. Several short steel bars 4 are buried in the vertical mortar joints of the frame-filled wall; the outer surface of the frame-filled wall 3 is coated with a 20mm thick high-ductility fiber concrete surface layer 5, and the high-ductility fiber concrete surface layer 5 fills the frame Wall 3 and all short bars 4 cladding. Its specific construction process is:

[0027] Step 1, build the frame filling wall 3, and embed the short steel bars 4 of the shear connectors in the vertical mortar joints of the frame filling wall; the horizontal spacing and the vertical spacing of adjacent short steel bars are both 300mm; the diameter of the short steel bars 4 used 12mm, length 120mm, protruding 20mm from the surface of the brick wall;

[0028] Step 2: Evenly apply a h...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com