Hydraulic circuit capable of accurately controlling lifting height of movable arm of excavator

A precise control, hydraulic circuit technology, applied in mechanically driven excavators/dredgers, etc., can solve the problems of inaccurate lifting and positioning of excavators, reducing the operating efficiency of hydraulic excavators, and inability to accurately control the boom cylinders, etc. Achieve the effect of improving work efficiency, simple structure and sensitive control action

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0011] The present invention will be further described below in conjunction with drawings and embodiments.

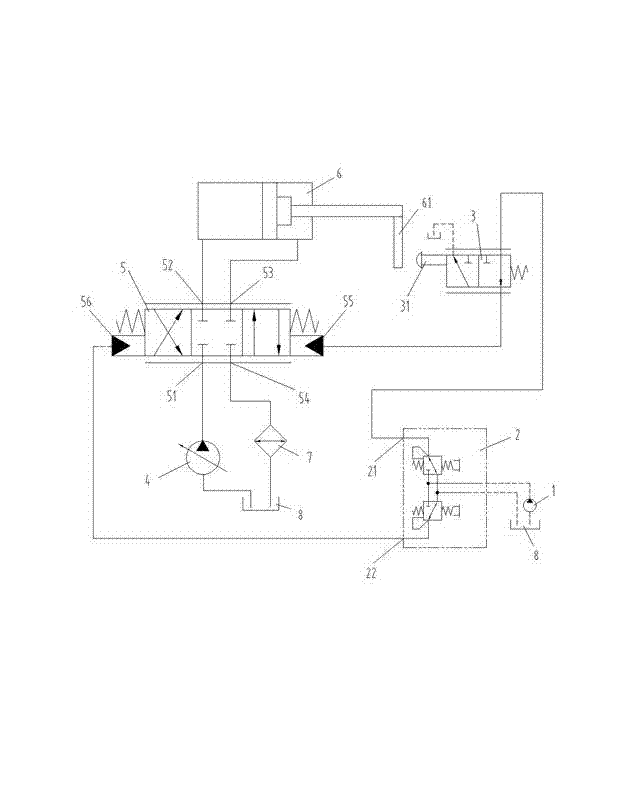

[0012] Such as figure 1 As shown, the present invention includes a pilot pump 1, a pilot control valve 2, a limit control valve 3, a main pump 4, a main hydraulic control valve 5 and a boom cylinder 6, and the limit control valve 3 is a two-position three-way stroke slide valve , the output port of the pilot pump 1 communicates with the oil inlet of the pilot control valve 2, the first oil outlet 21 of the pilot control valve 2 communicates with the first hydraulic control port 55 of the main hydraulic control valve 5 through the limit control valve 3, and the pilot control valve 2 The second oil outlet 22 communicates with the second hydraulic control port 56 of the main hydraulic control valve 5, the output end of the main pump 4 directly communicates with the oil inlet 51 of the main hydraulic control valve 5, and the first outlet of the main hydraulic control valve ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com