Multilayered fabric weaving machine

A technology of multi-layer fabrics and looms, applied to looms, textiles, jacquard machines, etc., can solve the problems of affecting the number of fabric layers, high cost, and reducing the number of heald frames, so as to achieve accurate average transmission ratio, improve work efficiency, The effect of increasing tension

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The present invention will be further described below in conjunction with accompanying drawing.

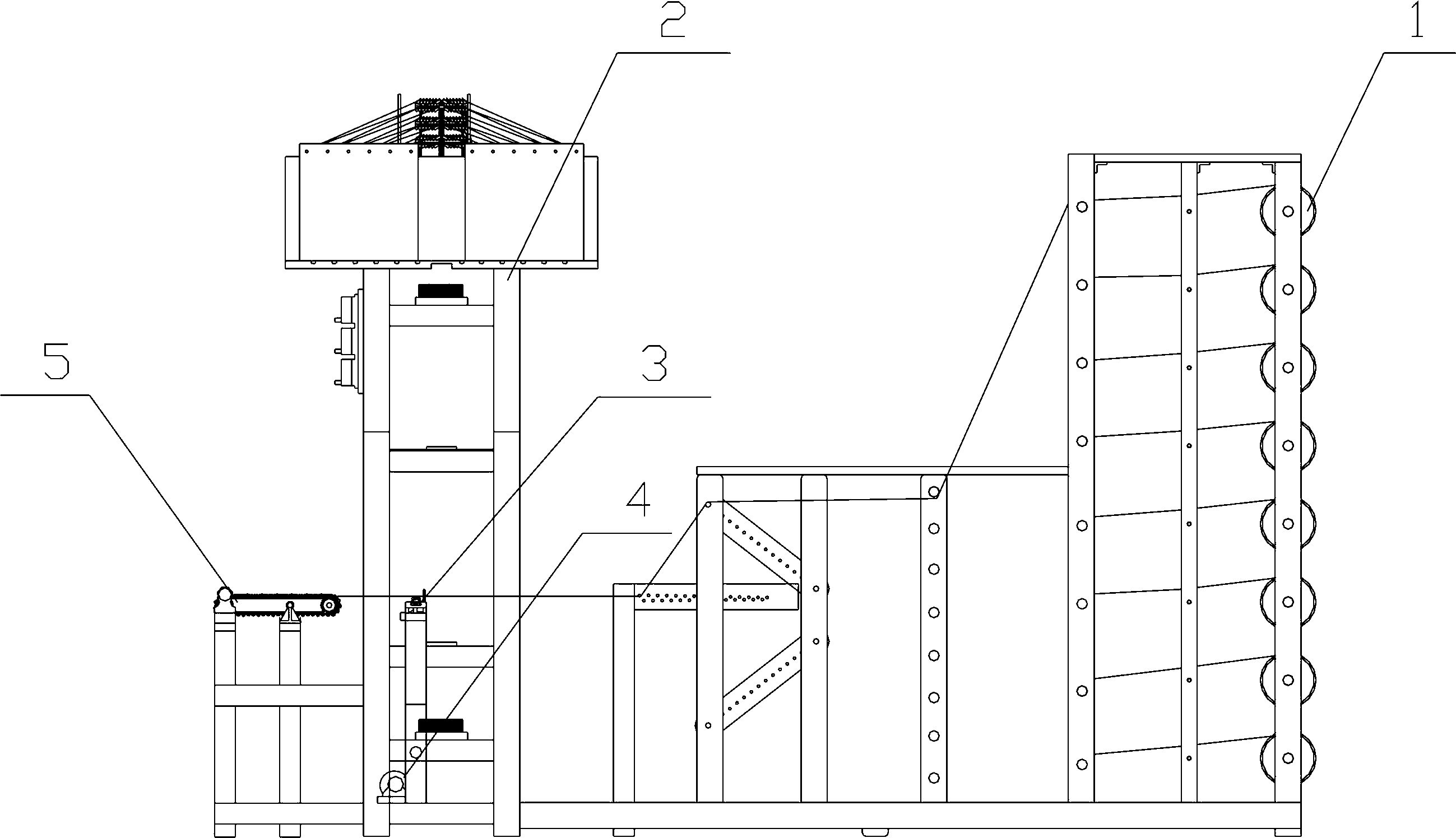

[0022] Such as figure 1 As shown, it includes a warp let-off mechanism 1, a heald lifting mechanism 2, a weft insertion mechanism 3, a weft beating mechanism 4, a curling mechanism 5, a let-off frame of the warp let-off mechanism 1 and a heald lifting frame of the heald lifting mechanism 2. The sides are fixedly connected by bolts, the crimping frame of the crimping mechanism 5 is fixed on the other side of the heald lifting frame by bolts, and the weft insertion frame of the weft insertion mechanism 3 is installed on both sides of the heald lifting frame by the short shaft 25 provided thereon. In the bearing hole 8 on the side, the weft beating mechanism 4 is connected with the weft insertion frame.

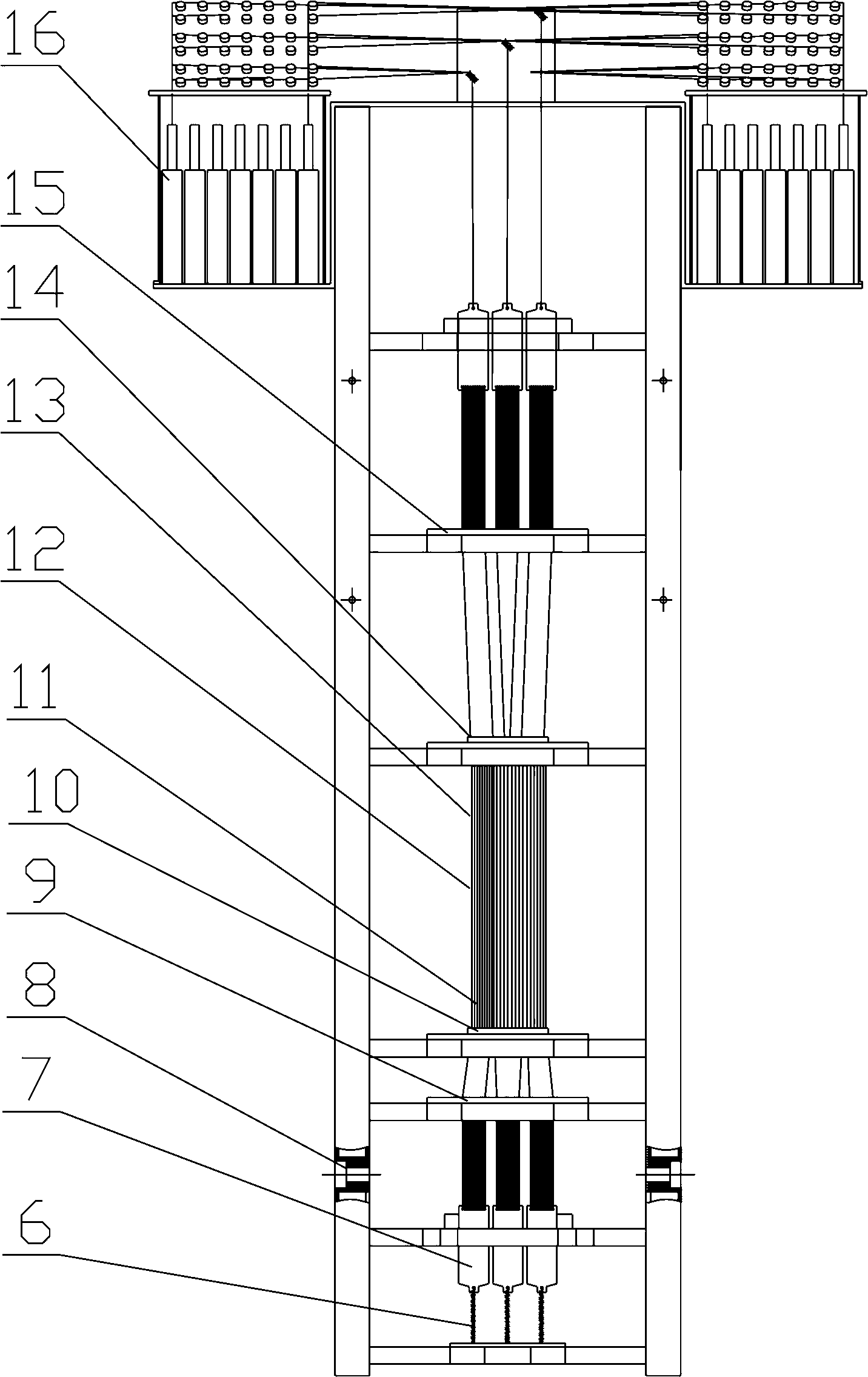

[0023] Such as figure 2 As shown, several heald lifting cylinders 16, some upper connecting plates, upper amplifying plate 15, upper eye plate 14, upper harness wire 13, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com