Spinning winder

A winding machine and spinning technology, which is applied in the direction of textiles and papermaking, conveying filamentous materials, and clustering of newly extruded filaments. The effect of the bend angle

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

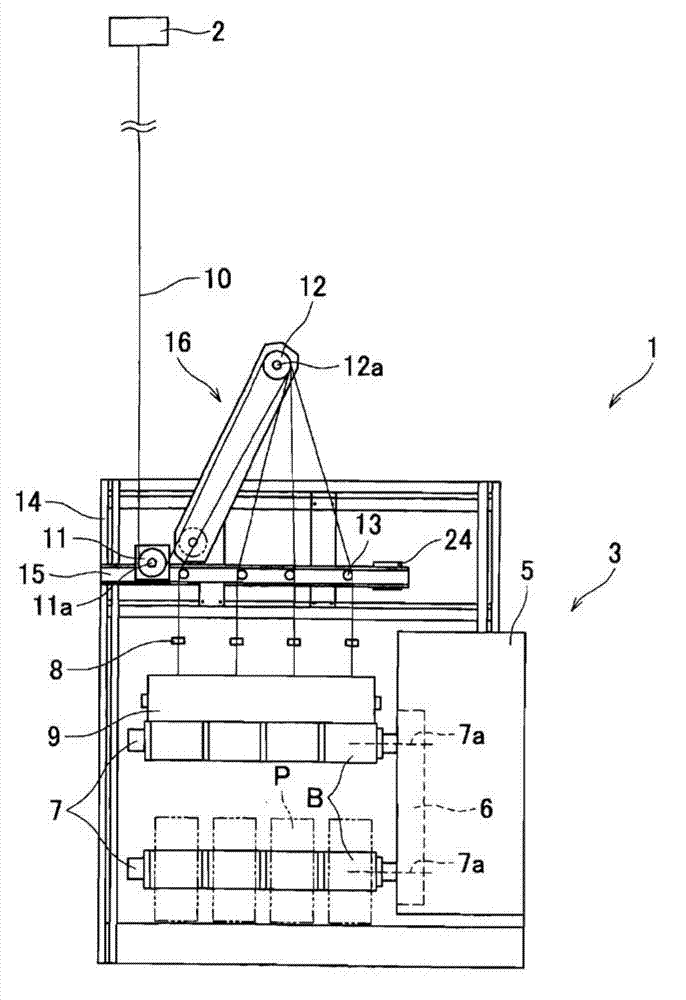

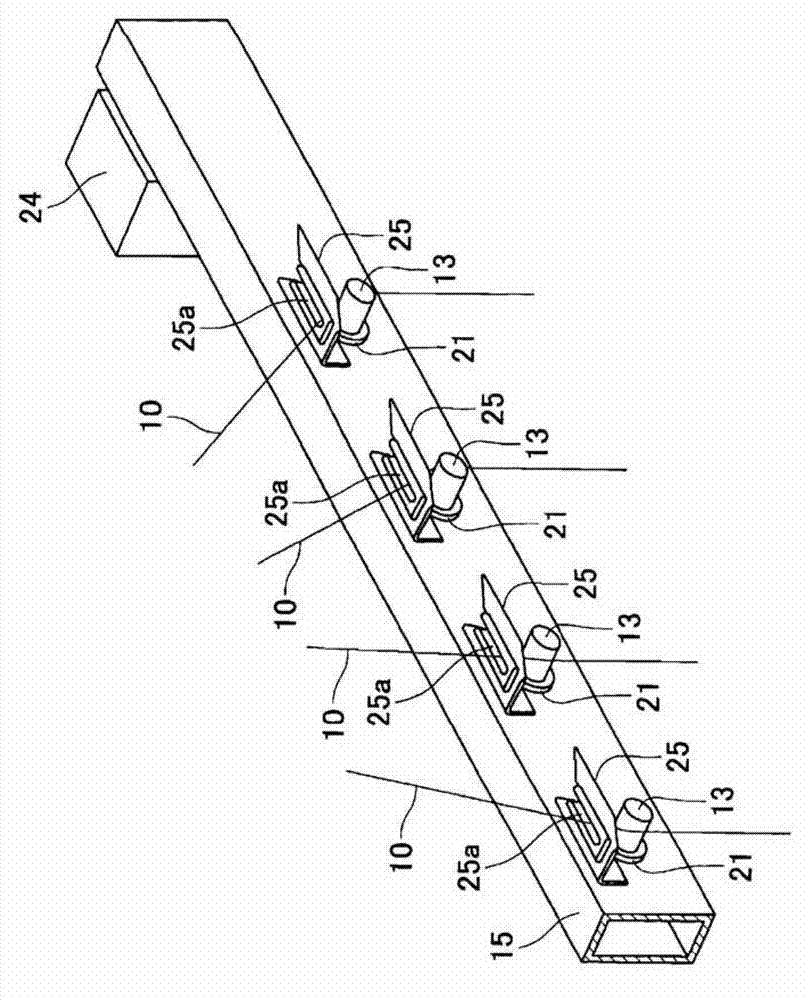

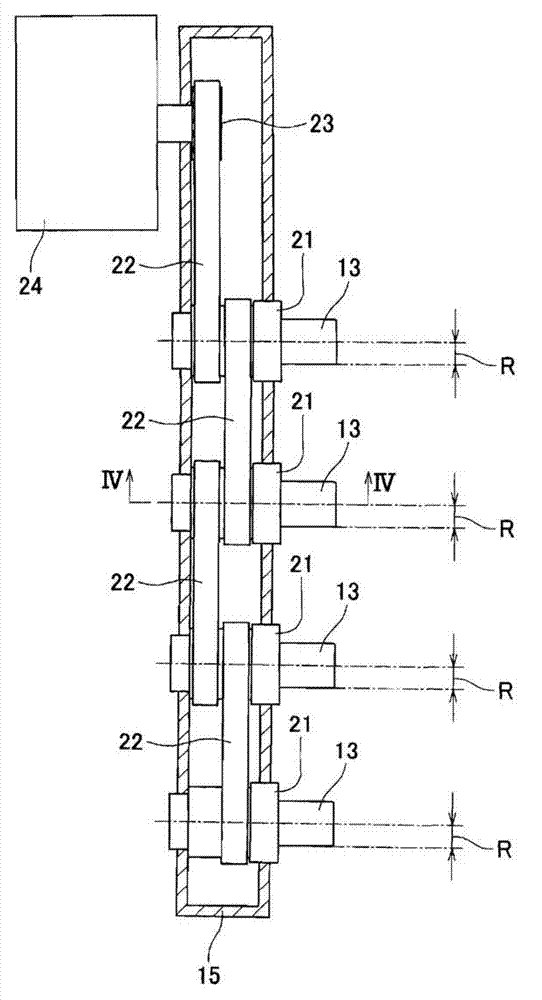

[0057] then use Image 6 Examples of the present invention will be described. Image 6 It is a diagram showing test results of yarn physical properties measurement of the yarn 10 performed downstream of the fulcrum guide 13 when the fulcrum guide 13 of various radii R distributes the spun yarn Y sent from the godet roll 12 . Wherein, the so-called physical property of the wire refers to the ratio of the tensile stress when the wire 10 is broken when the wire 10 is stretched and bent to the tensile stress when the wire 10 is broken when the wire 10 is not bent, and the higher the value, It means that the damage to the wire 10 at the fulcrum guide 13 is smaller. and, Image 6 It shows that the silk thread 10 is a multifilament of polyester material FDY, 150de, the winding angle θ of the silk thread 10 at the fulcrum guide 13 is 30°, the walking speed of the silk thread 10 is 4800m / min, and the ratio of the fulcrum guide 13 Experimental results when the yarn tension on the ups...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Bending angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com