Hollow tube joining structure of sewing machine

A joint structure and hollow tube technology, applied in the field of sewing machines, can solve problems such as abnormal operation of the mechanism, increased maintenance costs, vibration, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

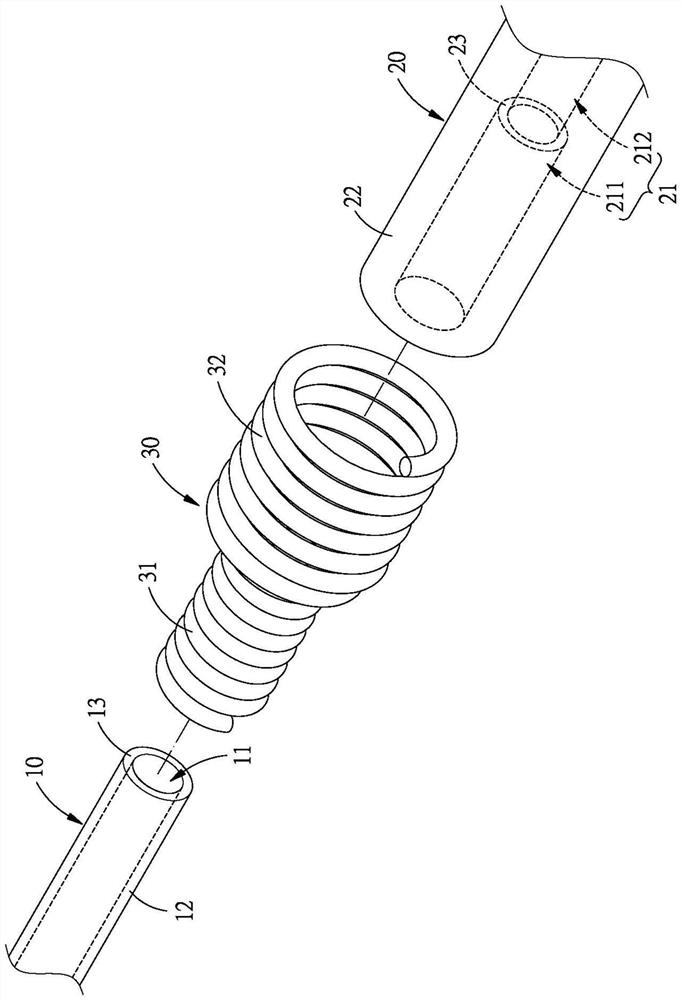

[0060] The first embodiment of the hollow tube joint structure of the sewing machine of the present invention is as figure 1 , 2 shown, including:

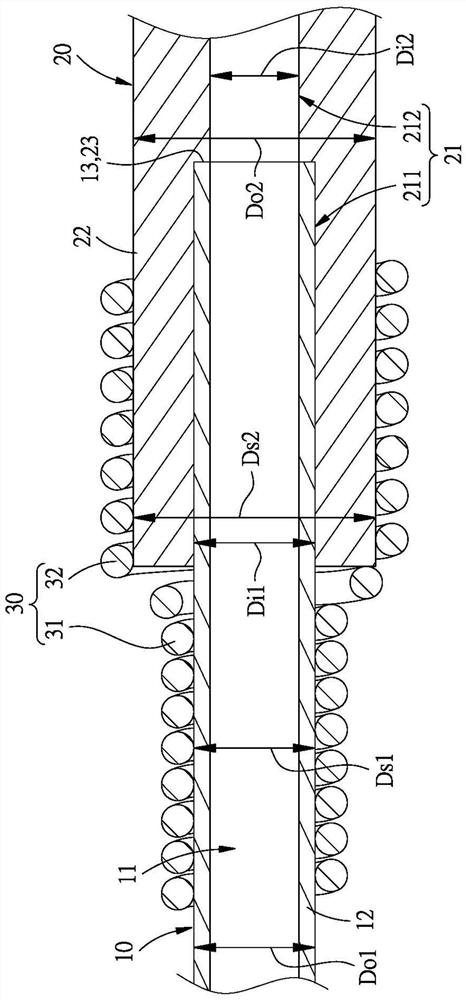

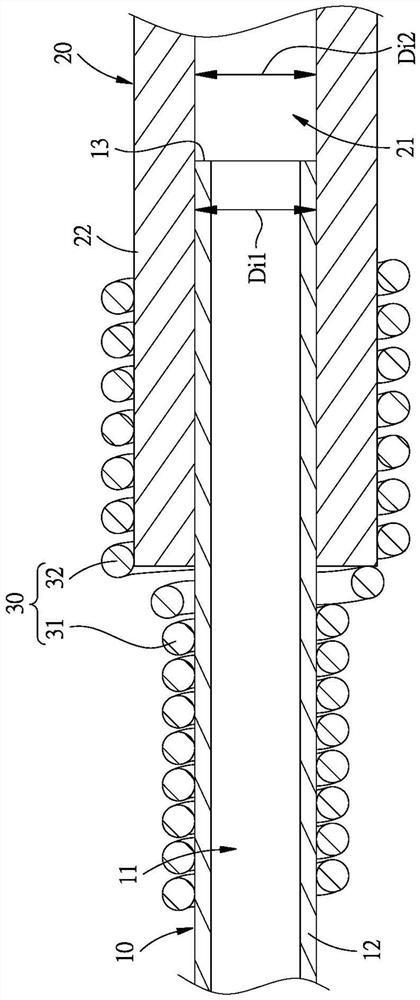

[0061] A first hollow tube 10 has a first through hole 11, the outer surface of the first hollow tube 10 is defined as a first tube surface 12, and the diameter length of the first hollow tube 10 is defined as a first Outer diameter Do1;

[0062] A second hollow tube 20 has a second through hole 21, and the second through hole 21 has a first hole segment 211 and a second hole segment 212 connected thereto. The first hollow tube 10 is inserted into the In the first hole section 211, the first through hole 11 and the second through hole 21 are communicated to define the outer surface of the second hollow tube 20 as a second tube surface 22, defining the second hollow tube 20 The diameter length of the second hole section 211 is a second outer diameter length Do2, the diameter length of the first hole section 211 is a first inner ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com