Prodigiosin high-producing strain and production method thereof

A technology for prodigiosin and its production method, which is applied to high-yield prodigiosin strains and its production field, can solve the problems of high cost, complex synthesis process, failure to implement large-scale chemical synthesis of Prodigiosin, etc., to reduce adverse effects, Effect of reducing energy consumption and noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

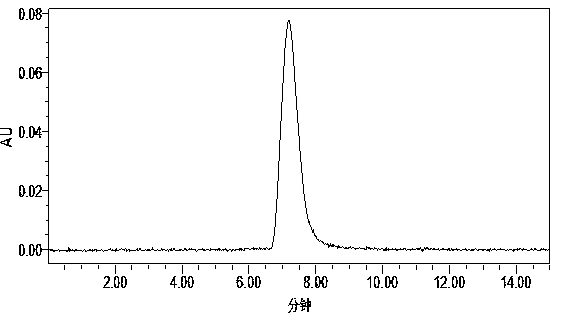

Image

Examples

Embodiment 1

[0034] Isolation and identification of strains

[0035]1) Enrichment medium (g / L): tryptone 10, yeast extract 5, NaCl 7.5, phenol 100 mg, pH 7.0; inorganic salt medium (g / L): ammonium nitrate 1, dihydrogen phosphate Sodium 0.5, dipotassium hydrogen phosphate 0.5, magnesium sulfate 0.2, calcium chloride 0.1, sodium chloride 0.2, pH 7.0. Add 2% agar powder to the corresponding solid medium, and add an appropriate amount of phenol to the phenol-containing medium.

[0036] 2) Inoculate 5 mL of sewage into 45 mL of enriched medium containing phenol, and incubate at 30°C and 130 r / min for 72 h. Take 1 mL each of the acclimatized bacterial solution and spread it on the inorganic salt medium plate containing phenol and incubate for 72 h at 30°C. The final concentrations of phenol are 100 mg / L, 300 mg / L, 500 mg / L, 700 mg / L respectively , 1000 mg / L. The colonies with good growth conditions were picked and separated by streaking on the enrichment medium plate, cultured at 30°C for 72 ...

Embodiment 2

[0045] Embodiment 2 Batch fermentation mode

[0046] Primary shake flask culture (250 mL Erlenmeyer flask): sucrose 19 g / L, peptone 10 g / L, sodium chloride 3 g / L, magnesium sulfate 2.4 g / L, liquid volume 50 mL, shaking speed 130 rpm, The pH was 6, and cultured at 30°C for 20-24 h.

[0047] Secondary shake flask culture (2 L Erlenmeyer flask): 1%-5% peanut powder medium, liquid volume 50 mL, shaking speed 130 rpm, pH 6, culture at 30°C for 20-24 h.

[0048] Three-stage fermentation culture (50 L fermenter): 1%-5% peanut powder medium, loading coefficient 0.6, stirring speed 200 r / min, dissolved oxygen 20%-40%, pH 6, 5% inoculum size, Incubate at 25-30°C for 30-40 hours. The yield of prodigiosin reached 6-8 g / L.

Embodiment 3

[0049] Embodiment 3 Batch fermentation mode

[0050] (1) Seeds on slant: Take the slant of the test tube or the glycerol seeds frozen at -80°C, inoculate it on the slant of the LB test tube, and incubate in a biochemical incubator at 30°C for 20-24 h.

[0051] (2) According to the 5% inoculum amount, the three-stage culture method is used for amplified culture.

[0052] Primary shake flask culture (250 mL Erlenmeyer flask): sucrose 19 g / L, peptone 10 g / L, sodium chloride 3 g / L, magnesium sulfate 2.4 g / L, liquid volume 50 mL, shaking speed 130 rpm, The pH was 6, and cultured at 30°C for 20-24 h.

[0053] Secondary shake flask culture (2 L Erlenmeyer flask): sucrose 19 g / L, peptone 10 g / L, sodium chloride 3 g / L, magnesium sulfate 2.4 g / L, glycerol 5 g / L, liquid volume 50 mL , shaking speed 130 rpm, pH 6, cultured at 30°C for 20-24 h.

[0054] Tertiary fermentation culture (50 L fermenter): 19 g / L sucrose, 10 g / L peptone, 3 g / L sodium chloride, 2.4 g / L magnesium sulfate, 10 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com