Re-improved inlet for third-generation light fighter

A technology for air intakes and fighter jets, which is applied in the field of re-improved air intakes for third-generation light fighters, and can solve problems such as surge, affecting engine thrust, and affecting the flight performance of fighter jets in air combat

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

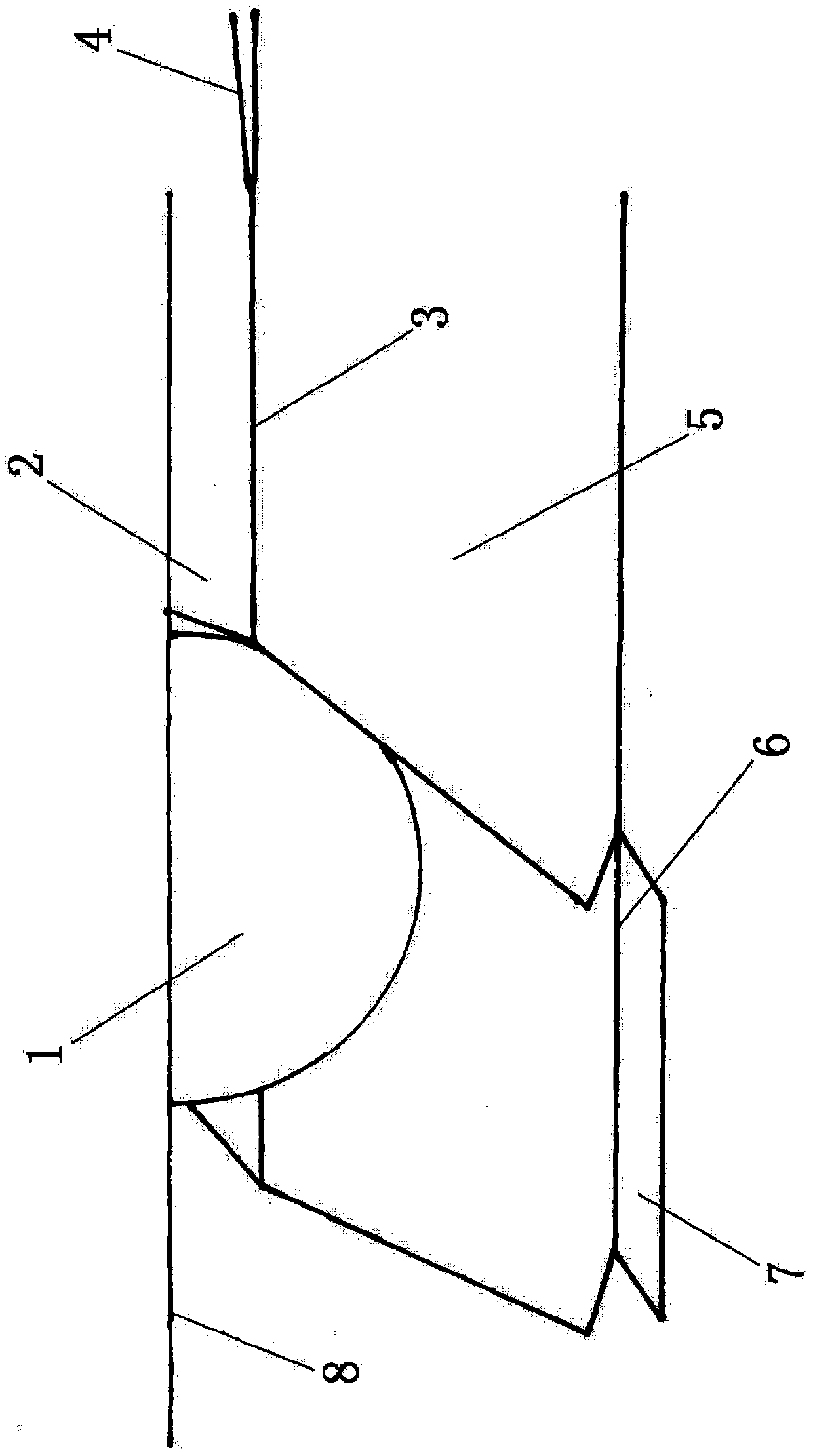

[0006] The present invention belongs to the improvement of the prior art, and mainly adds an adjustable lower lip 7 on the front edge of the lower wall 6 of the supersonic air inlet of the existing light third-generation fighter without a boundary layer partition. Change the vertical shape of the air inlet side wall into a shape consisting of two parts: the outer fan part 2 of the air inlet side wall and the inward part 5 of the air inlet side wall, and form an adjoining line 3 at its bend, and Keep the inlet sidewall protrusions at the same level as the wings.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com