A core nacelle for cooling air intake self-regulating helicopter engine based on one-way memory alloy

A technology of memory alloy and engine, which is applied in the cooling system of the power unit, the power unit of the aircraft, the components of the aircraft power unit, etc., and can solve the problems of increasing the amount of cooling air, reducing the exhaust temperature, increasing the weight and complexity of the engine system, etc. , to achieve the effect of reducing flight resistance and reducing the reflection cross-sectional area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

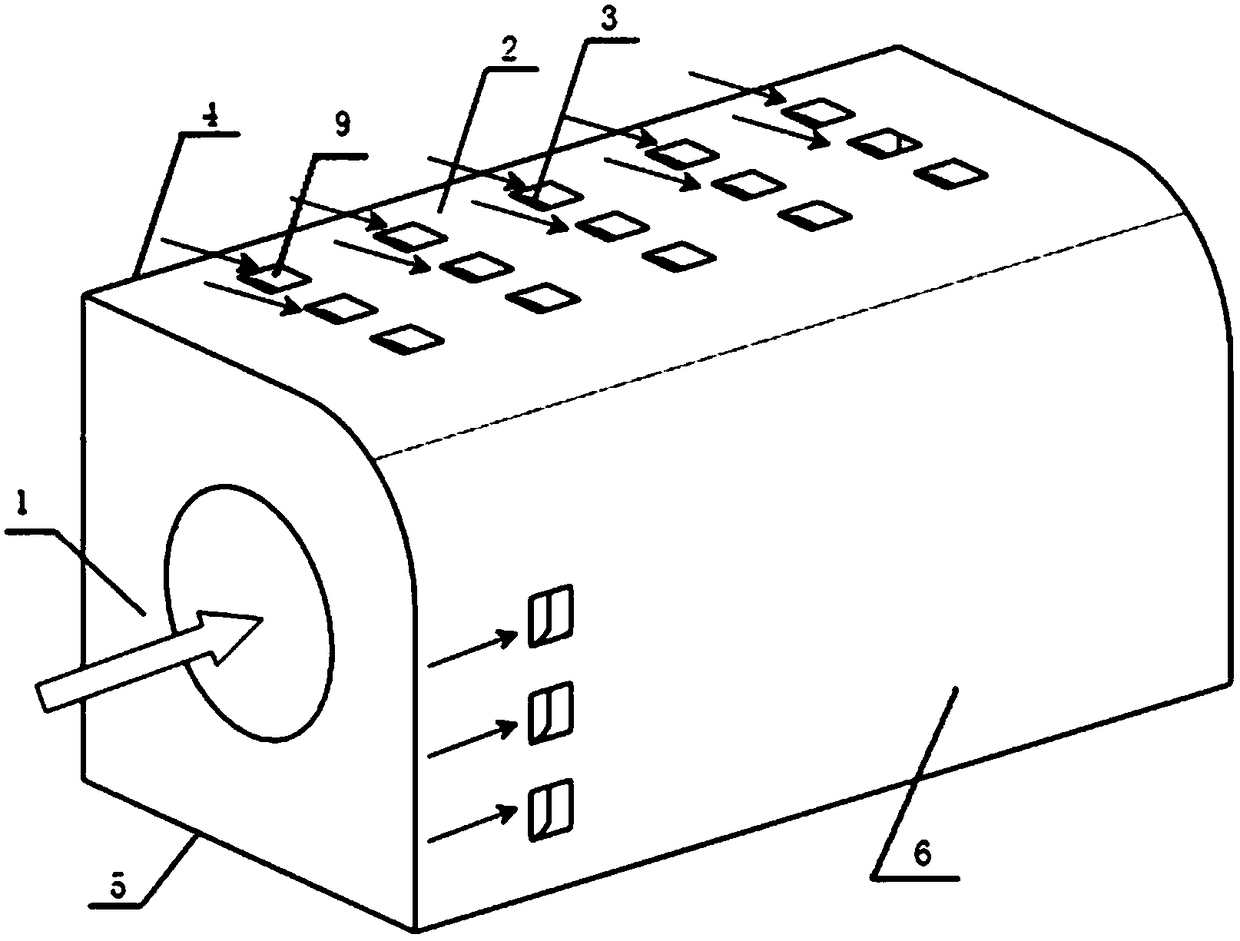

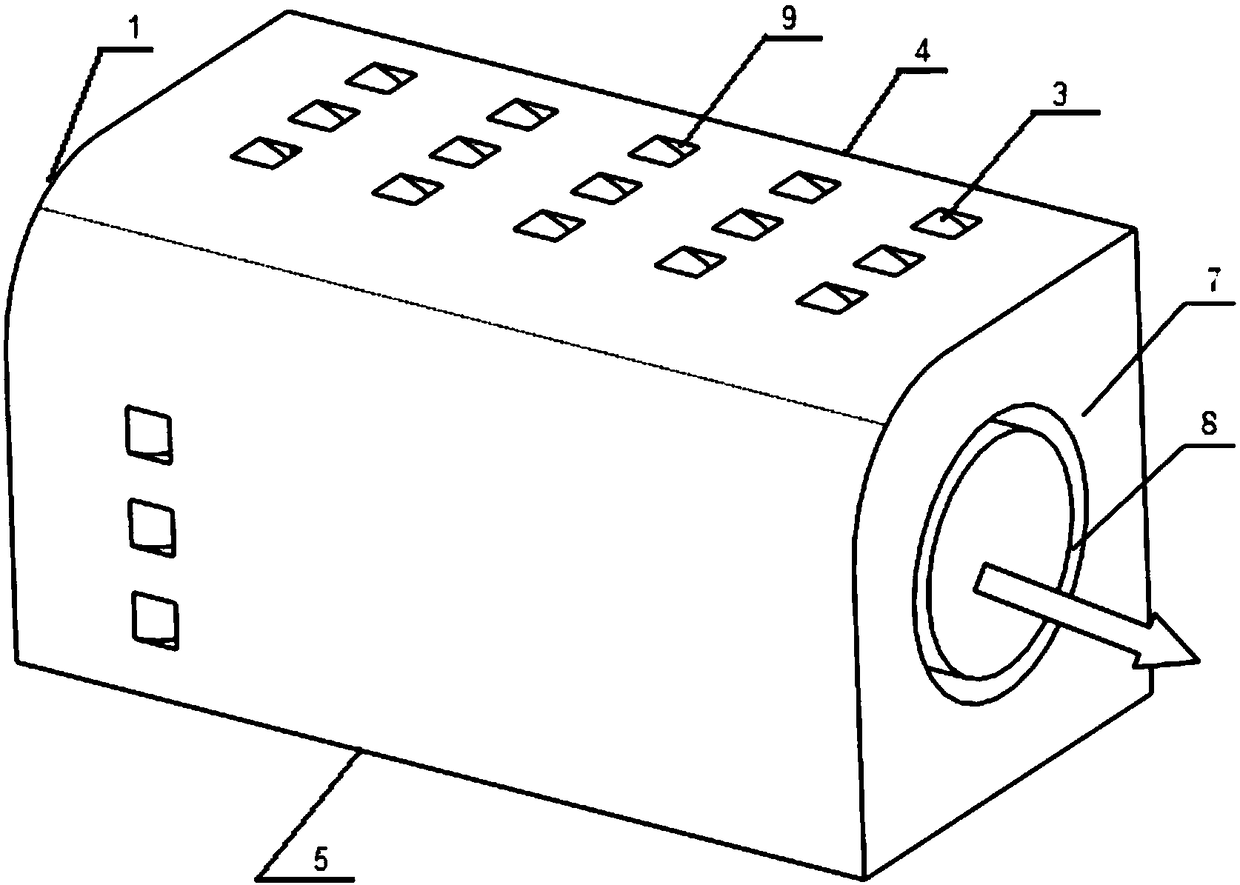

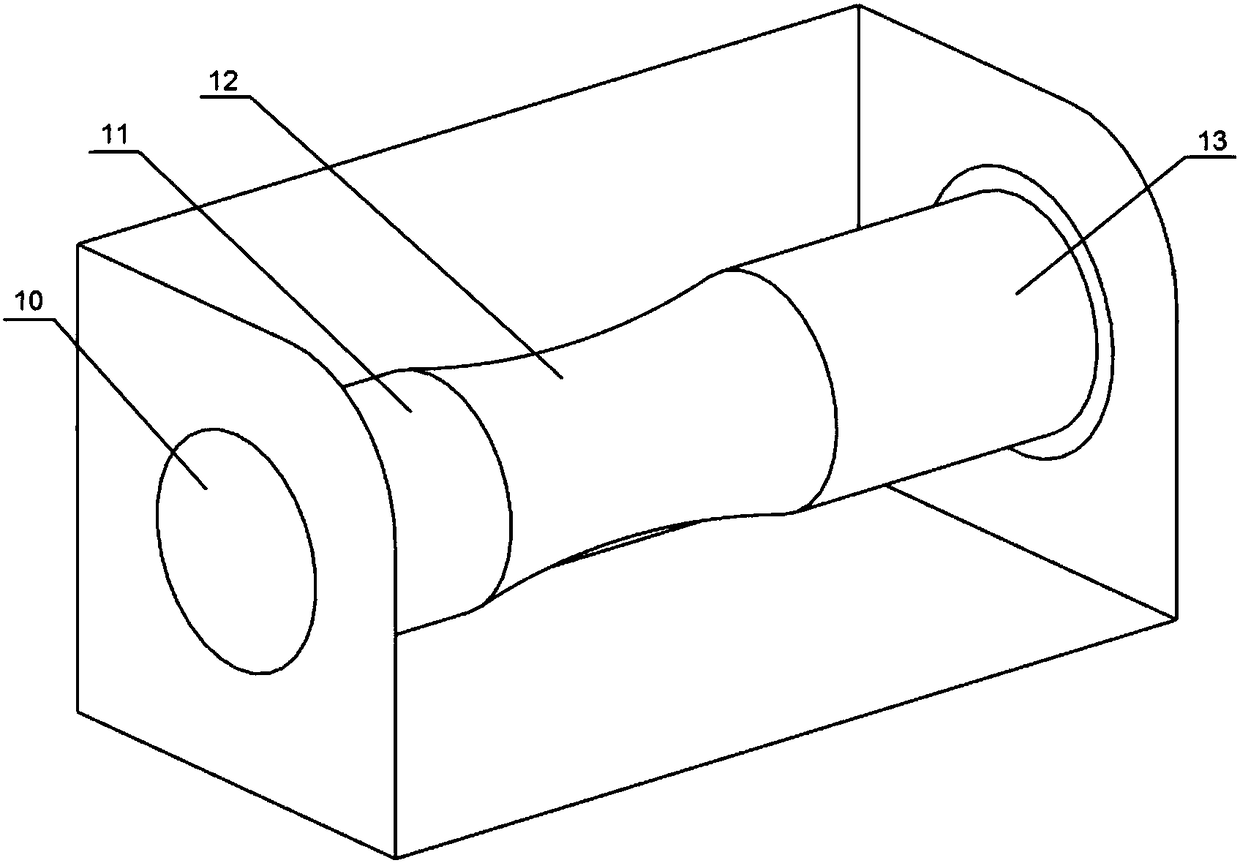

[0016] A cooling intake self-adjusting helicopter engine core cabin based on one-way memory alloy, including a front firewall, a rear firewall, a side firewall, a lower firewall, an upper wall of the engine core cabin, a side wall of the engine core cabin, and a rear firewall. Engine core nacelle cooling air outlet. An engine air intake 10 is arranged on the front firewall 1 . There is an annular gap between the turbine outlet 14 and the rear firewall 7, which is the engine core cabin cooling air outlet 8. In the engine core nacelle, the compressor casing 11, the combustion chamber casing 12 and the turbine casing 13 are the main heat sources in the engine core nacelle. When the engine is running, a large amount of heat is emitted into the engine core nacelle through their surfaces. Several openings 9 are arranged on the upper wall 2 of the engine core nacelle and the side wall 6 of the engine core nacelle, and each opening 9 is covered with a sheet-shaped one-way memory allo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com