Automatic feeding device for pressing engine cylinder head locking clamp

An engine cylinder head and automatic feeding technology, which is applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve problems such as low efficiency and potential safety hazards, and achieve the effects of simplifying the operation process, ensuring safety, and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

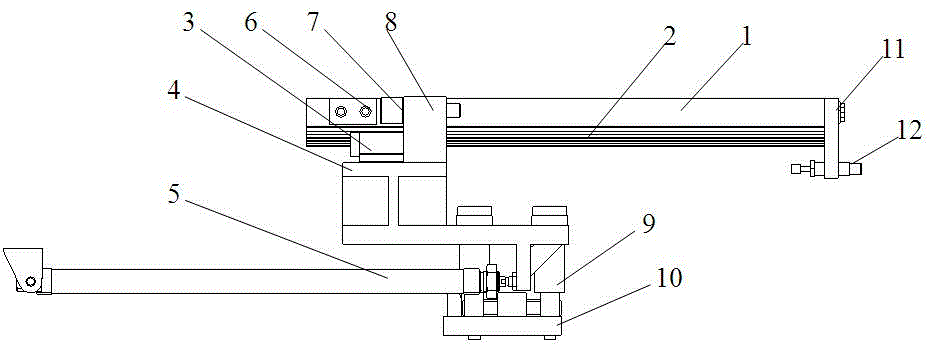

[0039] Such as figure 1 Shown is the use and operation method of the present invention: when working, press the start button, the cylinder of the automatic feeding device is ejected to make the feeding template 14 stretch out of the equipment, and the operator respectively puts a group of press-fitting parts (general lock clips) 22 and the spring upper seat 21 are combined pressing parts) are placed in each feeding positioning hole 19 of the feeding template 14. Press the back button, the cylinder of the automatic feeding device will be retracted so that the feeding template 14 retracts into the equipment, the feeding template 14 enters the press-fitting station, the indenter falls vertically and inserts into the indenter guide ring 20, and passes through the holding mechanism Take the press-fit out. The pressure head rises, the cylinder is ejected again, and the feeding template 14 stretches out of the feeding station outside the equipment again, completing a complete loadin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com