Hydrocyclone used for three-phase medium separation

A hydrocyclone and medium technology, applied in the direction of the cyclone device, the device in which the axial direction of the cyclone can be reversed, etc., can solve the problems of speed loss, fluid energy loss, affecting the three-phase separation efficiency, etc., to improve the purity , the effect of simplifying the treatment process and broad engineering application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

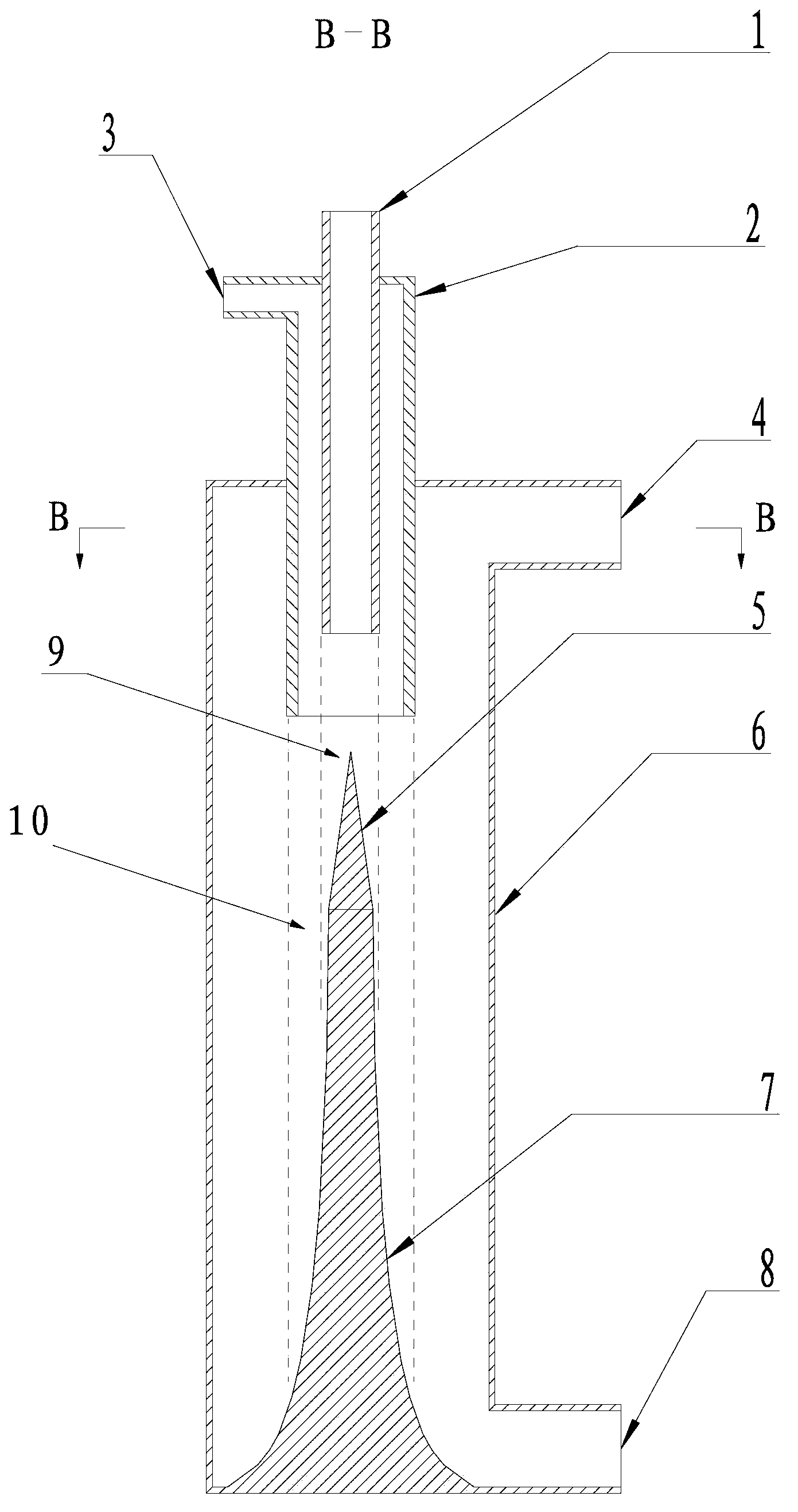

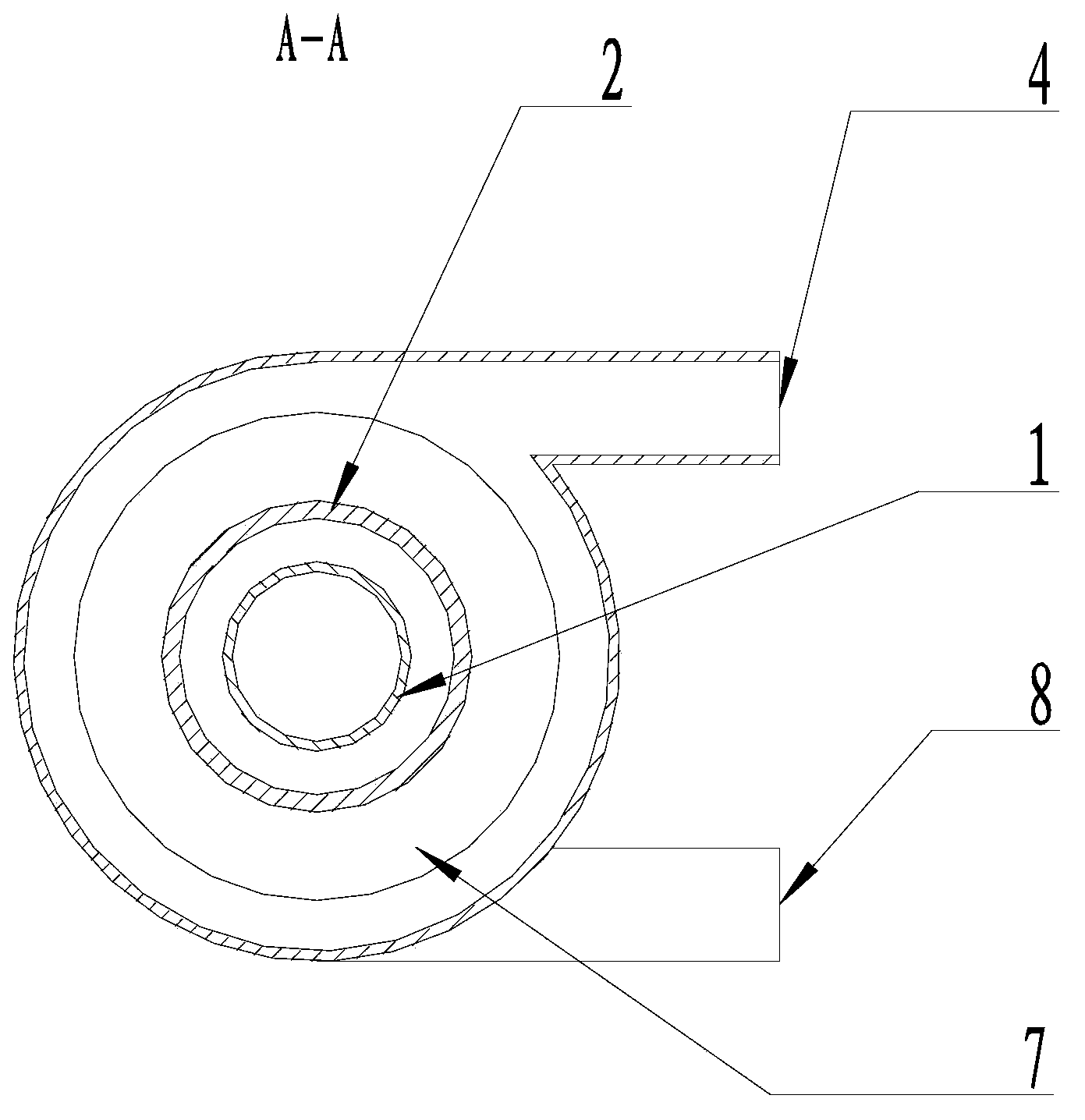

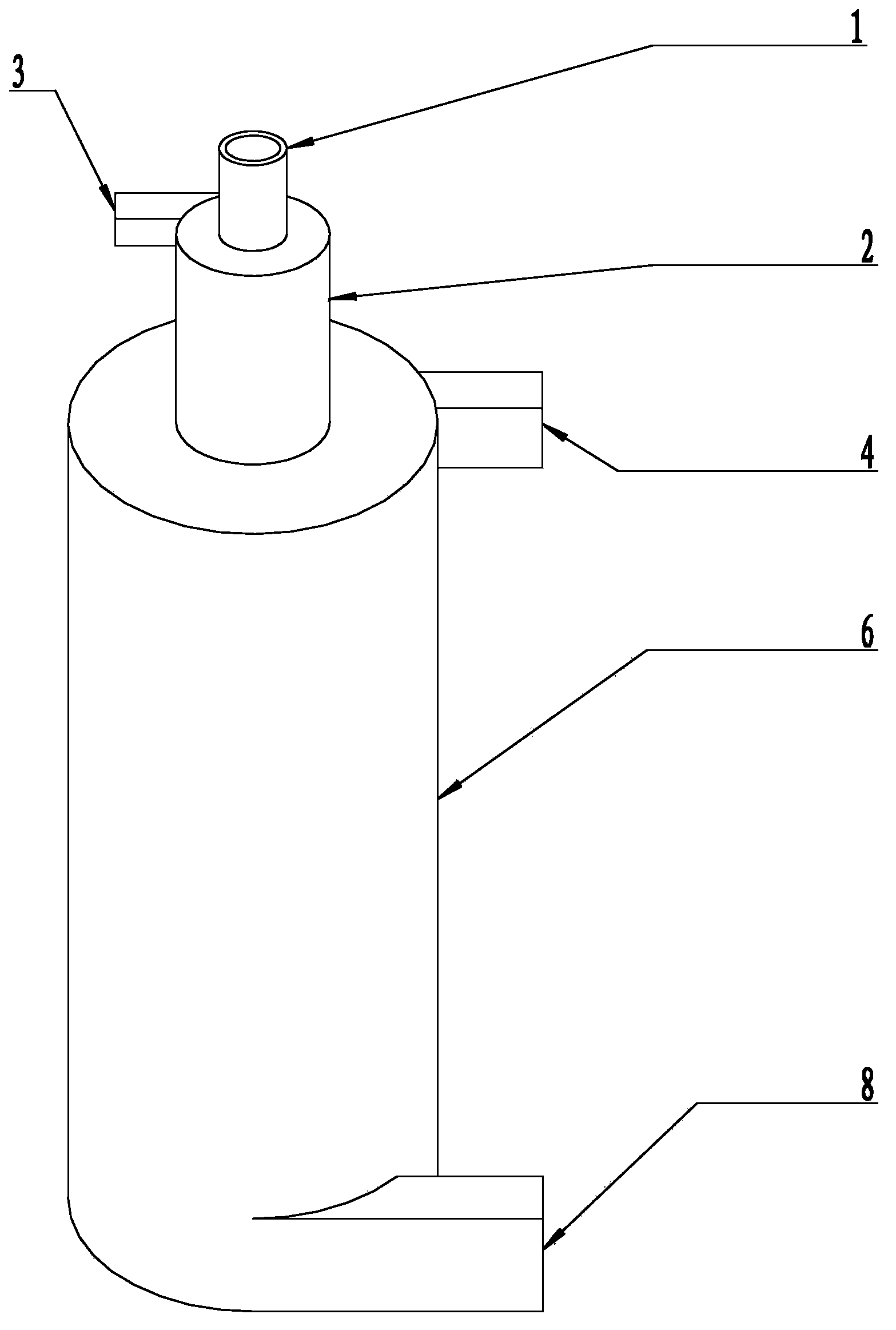

[0012] The present invention will be further described below in conjunction with accompanying drawing:

[0013] Depend on Figure 1 to Figure 3 As shown, this kind of hydrocyclone for the separation of three-phase media includes a cylindrical hollow swirl tube 6 and upper and lower end caps for closing the swirl tube, and the upper and lower end caps The inner side of the swirl tube is respectively provided with a tangential inlet pipe 4 and an underflow outlet pipe 8 connected tangentially to the outer circumference of the swirl pipe. On the basis of the above prior art, the improved features of this scheme are:

[0014] At the bottom end of the swirl tube 6 is fixed a curved guide body formed by connecting a straight cone 5 and a curved cone 7, and the generatrix of the curved cone is an ellipse with a gradually increasing slope.

[0015] In addition, passing through the upper end cover of the swirl tube, an overflow body formed by connecting the secondary overflow pipe 2 a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com