Method and apparatus for fibrillating synthetic ribbons

A technology for fibrillating rollers and ribbons, applied in fiber processing, textiles and papermaking, filament/thread forming, etc., can solve the problems of ribbon strength loss, untidy tearing edges, etc., and achieve the effect of precise guidance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

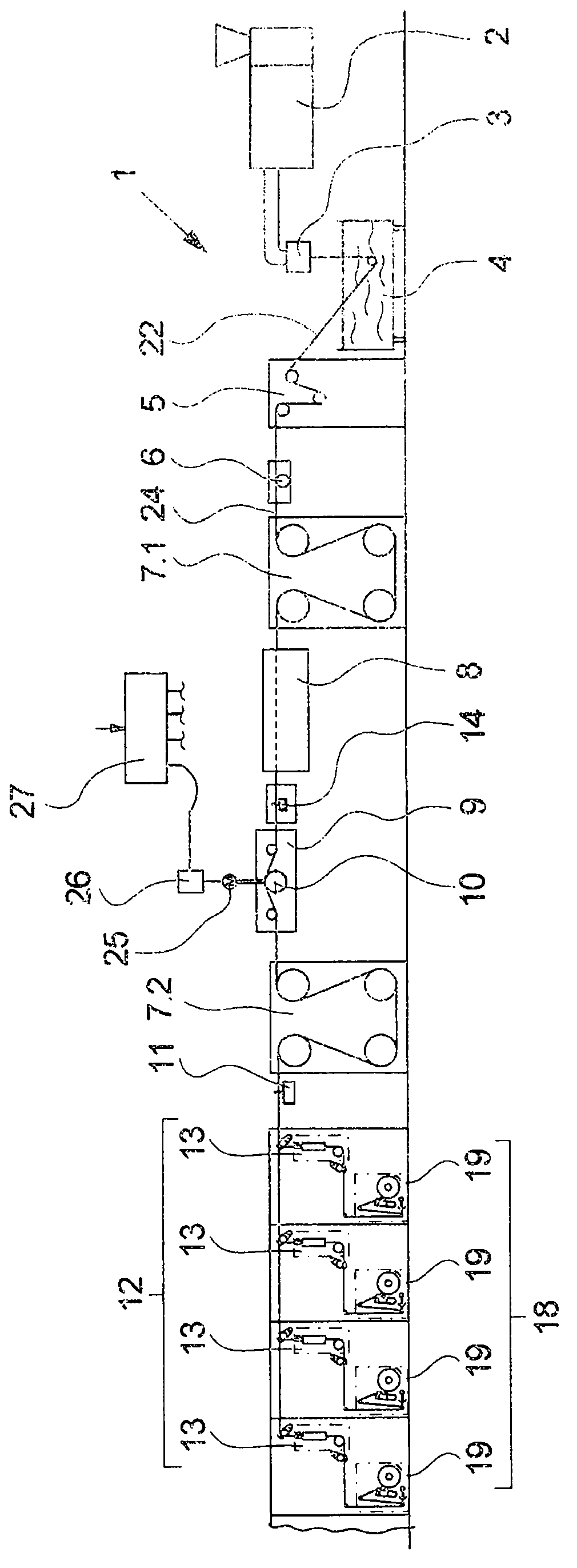

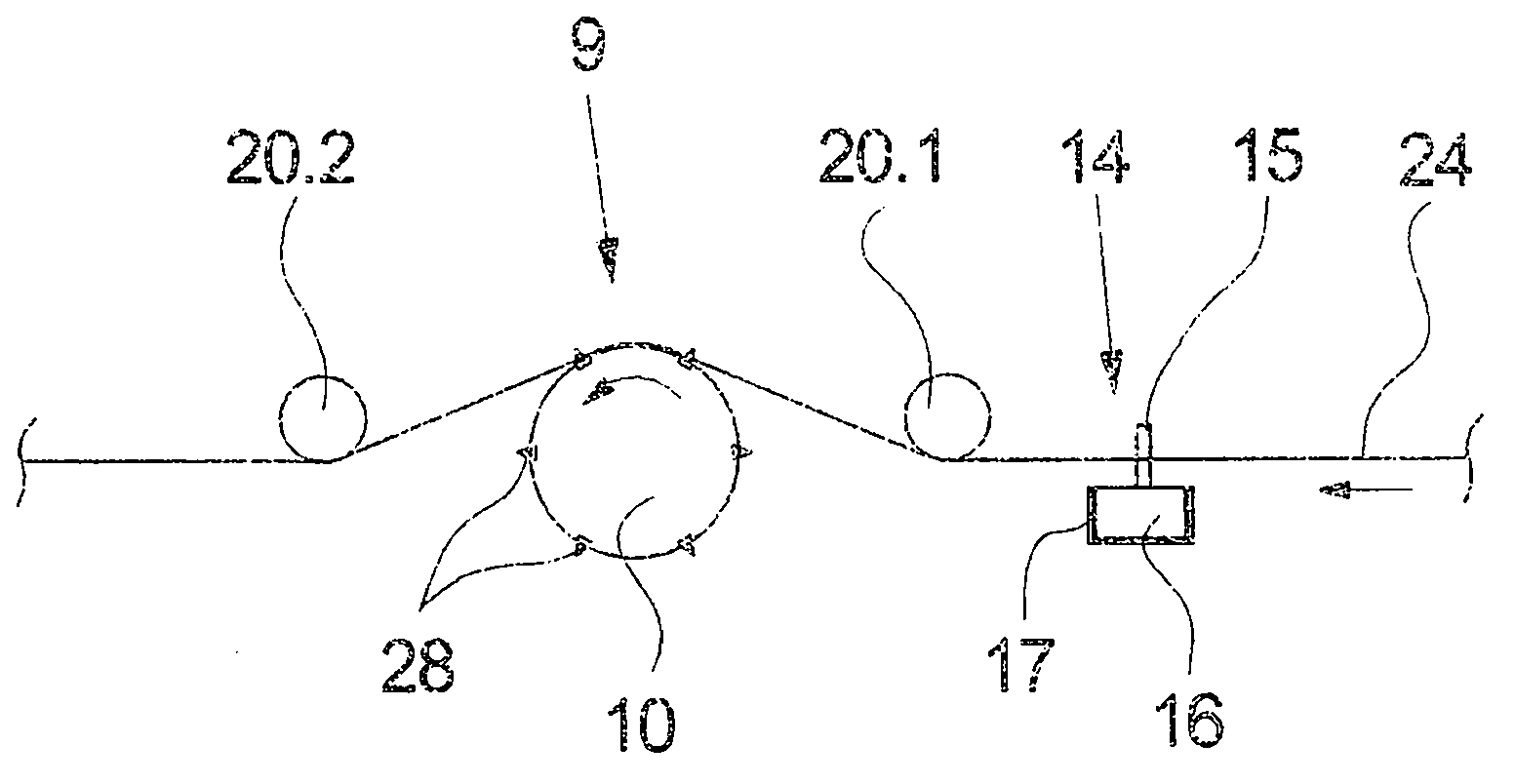

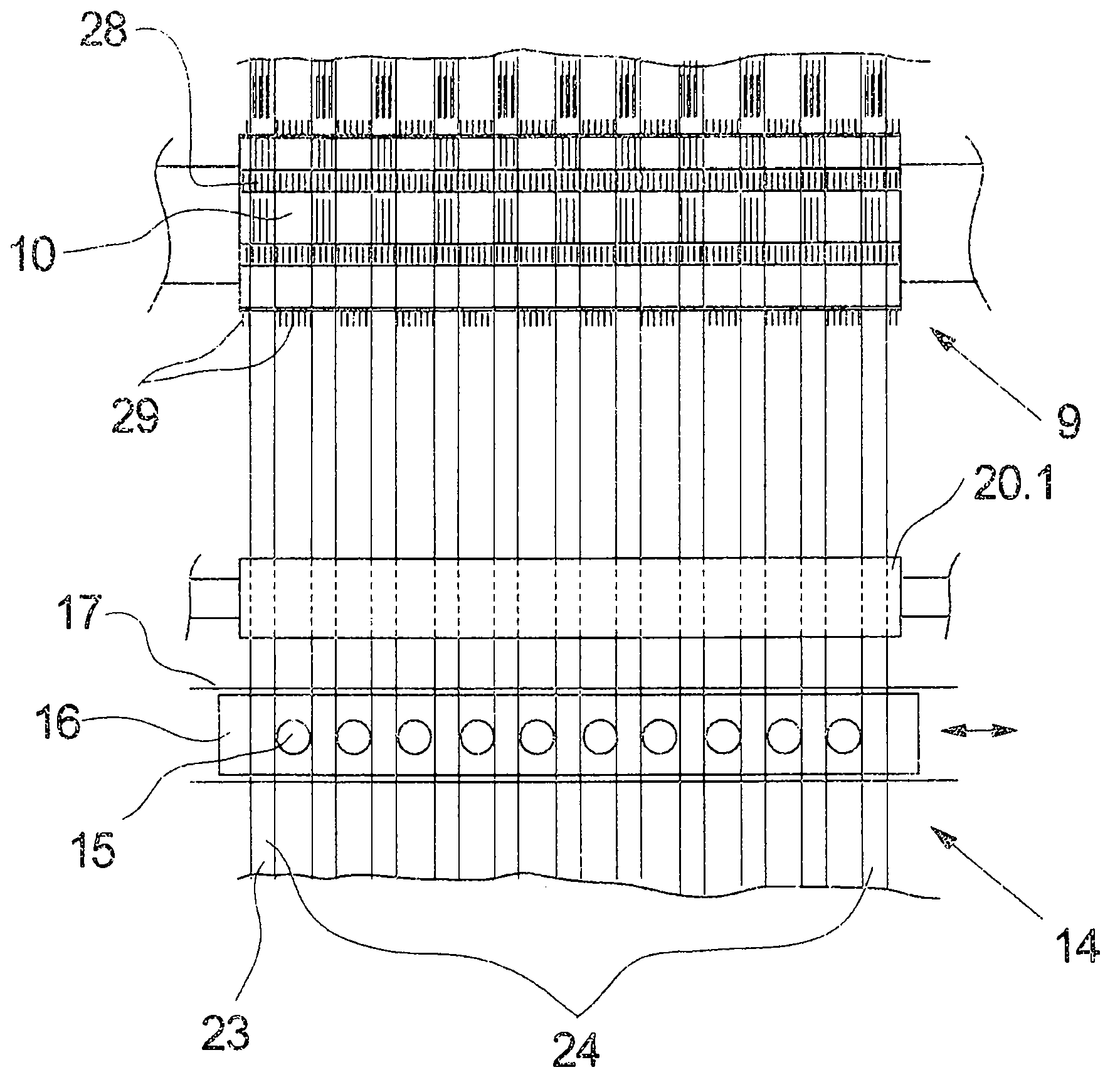

[0033] exist Figures 1 to 3 An embodiment of a device according to the invention for carrying out the method according to the invention for fibrillating a bundle of ribbons in an extrusion process is schematically shown in . Said example is in figure 1 In general view, in figure 2 in a partial view from the side in the fibrillated region and in the image 3 Shown in partial view in top view. The description that follows applies to all figures, as long as no figure is explicitly referenced.

[0034] exist figure 1 An embodiment of the device according to the invention is shown in a general view in . The exemplary embodiment has an extrusion device 1 to produce a film from a thermoplastic material. In this exemplary embodiment the extrusion device 1 has an extruder 2 . The extruder 2 is connected to an extrusion head 3 which extrudes a flat film 22 from the thermoplastic material melted by the extruder 2 .

[0035] It should be mentioned here that the extrusion device ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com