Loudspeaker device and manufacturing method thereof

A manufacturing method and loudspeaker technology, applied in the field of electroacoustics, can solve the problems of reducing the working reliability and stability of the loudspeaker device, increasing the damage probability of the loudspeaker device, and the cumbersome manufacturing process of the loudspeaker device, so as to shorten the production cycle and reduce damage Probability, the effect of simplifying the electrical connection steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] Below in conjunction with accompanying drawing and embodiment, further elaborate the present invention.

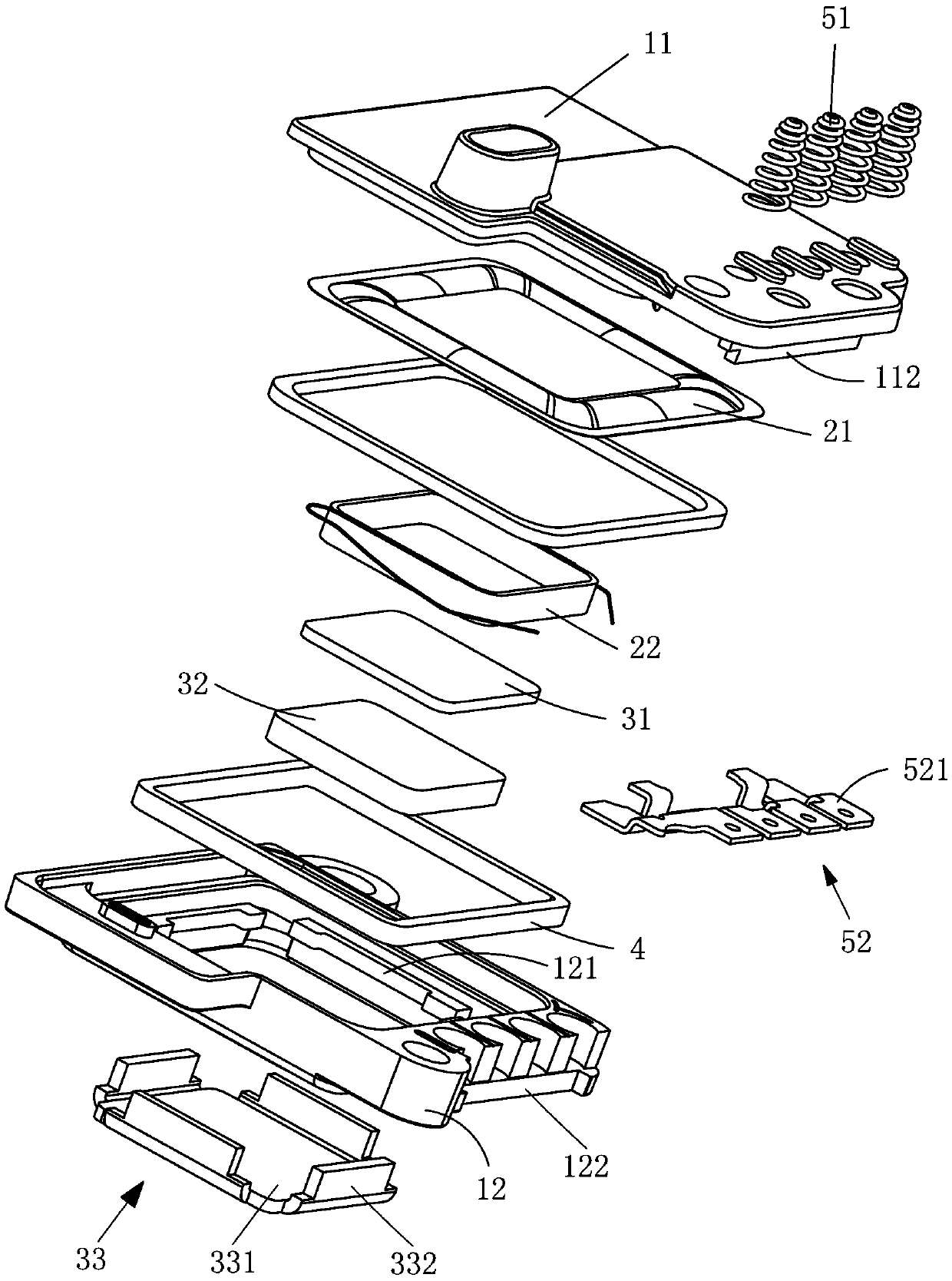

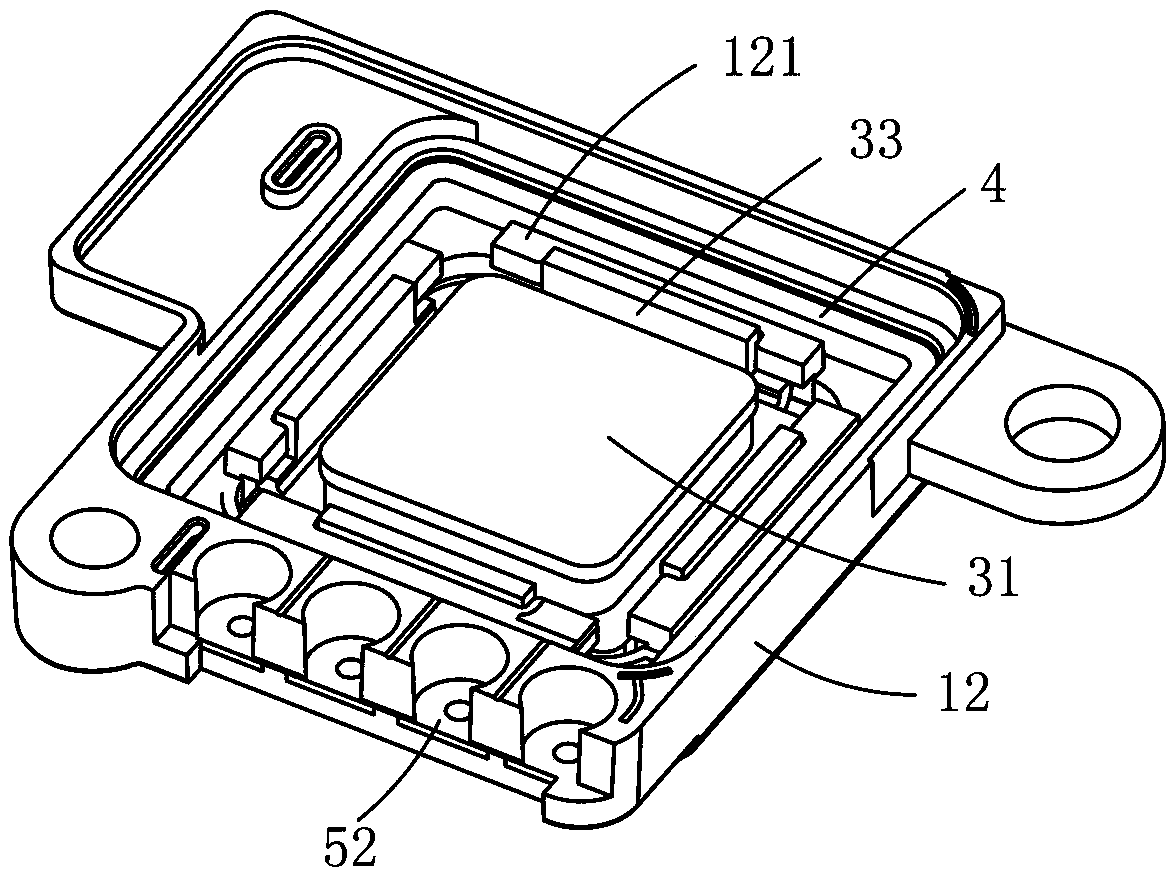

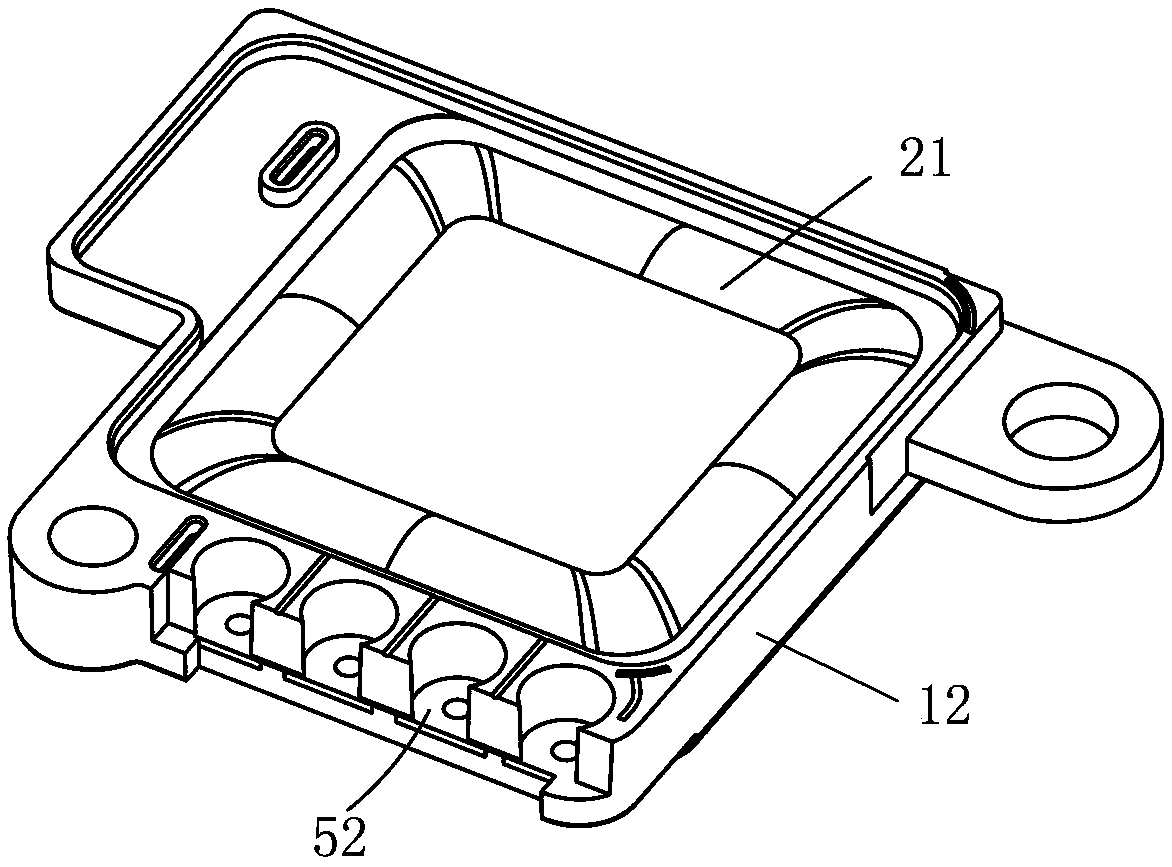

[0031] Such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 and Figure 6 Commonly shown, a loudspeaker device includes a combined first housing 11 and a second housing 12, and a cavity surrounded by the first housing 11 and the second housing 12 accommodates a vibration system and a magnetic circuit system; the loudspeaker device also includes a connection assembly for electrically connecting the vibration system and an external circuit, the connection assembly includes a conductive sheet 52 injection-molded with the second housing 12, and the conductive sheet 52 simultaneously connects the vibration system and the conductive material. The spring 51 is connected to an external circuit; the first housing 11 is provided with a through hole 111 for receiving the spring 51 ; the spring 51 is a conical spring, and the through hole 111 is matched with the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com