A method for co-simulation analysis of rail transit vehicle door system dynamics

A rail transit vehicle and co-simulation technology, applied in the field of co-simulation analysis of rail vehicle door system dynamics, can solve problems such as unreported simulation analysis of rail vehicle door systems, achieve low-cost design goals, reduce risks, and high economic benefits Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

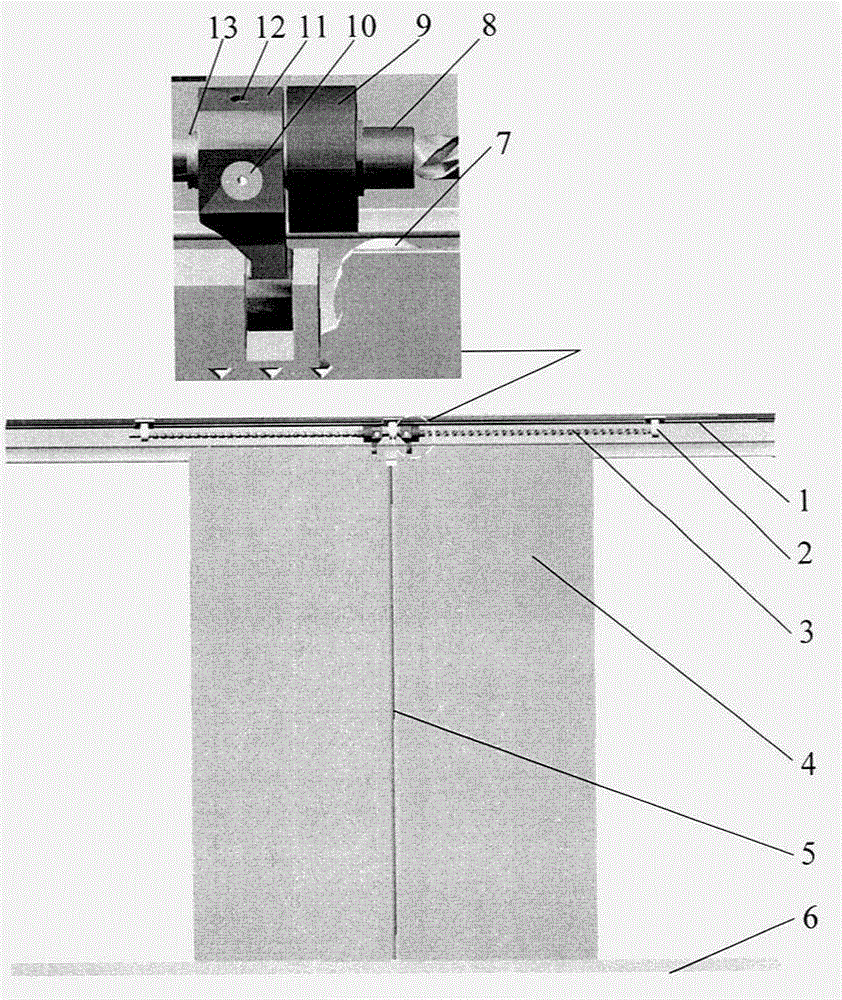

[0060] This embodiment is used for dynamic co-simulation analysis of the door system, and the involved components include a virtual prototype model of the door system and a control module.

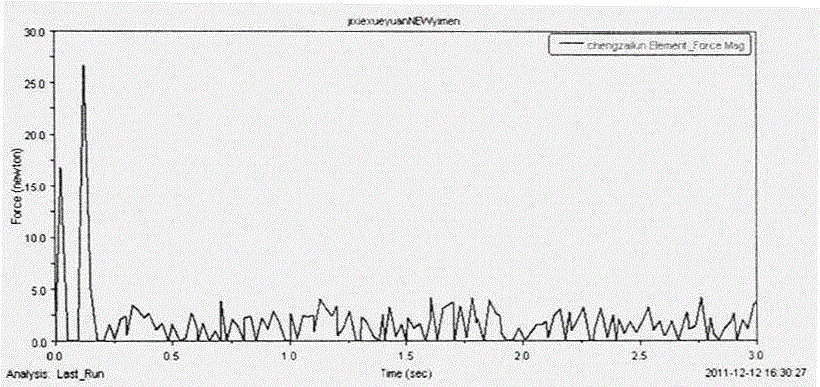

[0061] In this embodiment, by simulating the door opening process of the rail vehicle door system, the force situation of the load-carrying wheel is output during the door-opening process, and the force of the load-carrying wheel in the three-dimensional direction of the output can be used to control the fatigue of the load-carrying wheel. The life analysis is carried out, and the reliability design of the bearing wheel is carried out, which provides an important theoretical basis for the optimal design of the bearing wheel.

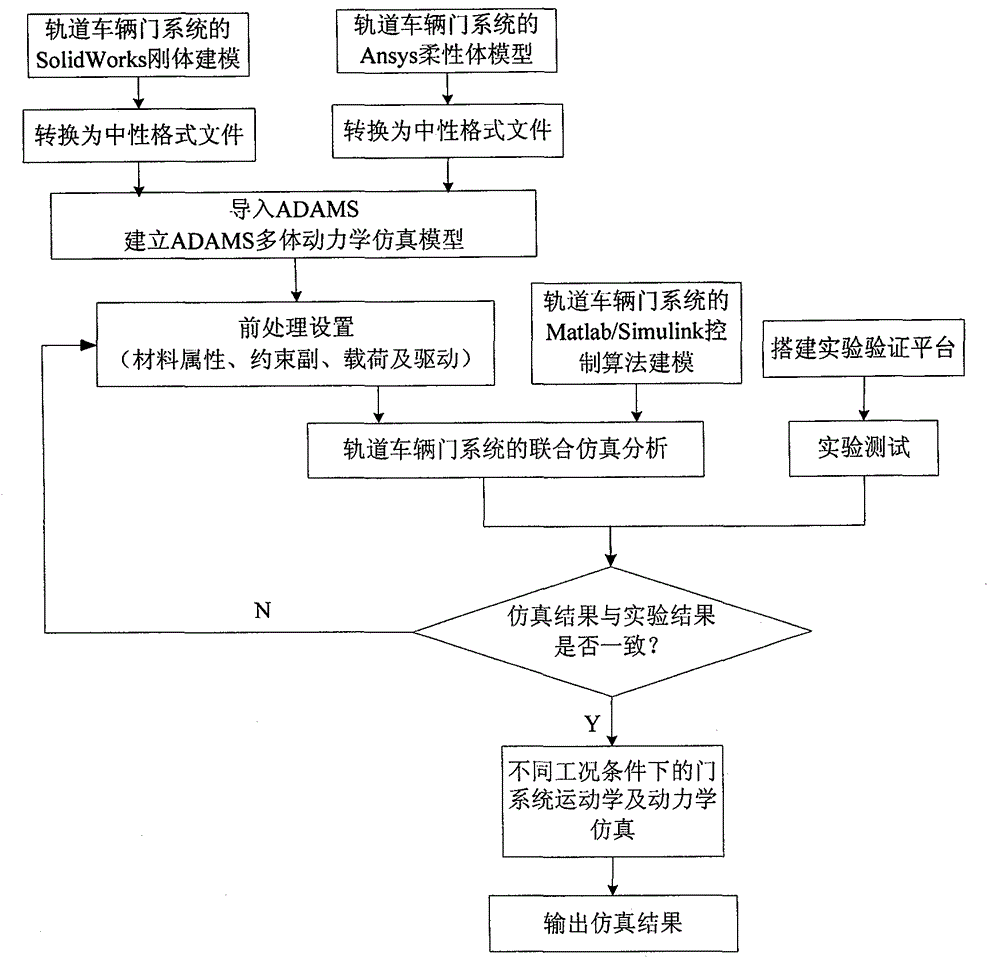

[0062] In the use of the embodiment of the present invention of the above-mentioned experimental research, the basic flow is as follows:

[0063] The first step is to open the virtual prototype model of the rail vehicle door system that has been imported into ADAMS, ...

Embodiment 2

[0069] This embodiment is used for dynamic co-simulation analysis of the door system, and the involved components include a virtual prototype model of the door system and a control module.

[0070] In this embodiment, by simulating the door opening process of the rail vehicle door system, the displacement, velocity, and acceleration curves of the door system during the door opening process are output to evaluate the stability of the door system operation. The output force of the lock pin in the locking device of the key component of the door system is used for the evaluation of the operation safety of the door system, and provides an important theoretical basis for the optimal design of the key components of the door system.

[0071] In the use of the embodiment of the present invention of the above-mentioned experimental research, the basic flow is as follows:

[0072] The first step is to open the co-simulation platform, set the parameters of the prototype model of the vehic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com