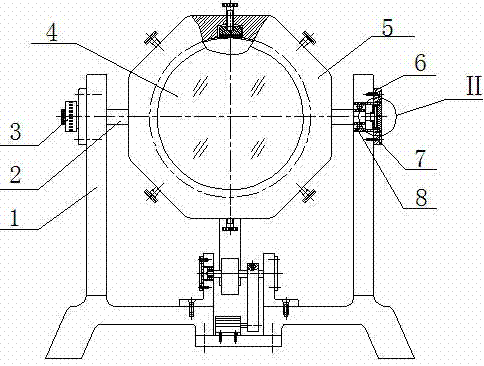

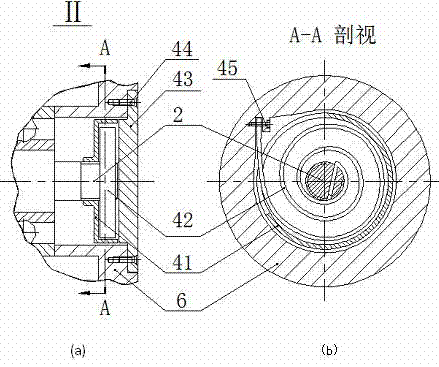

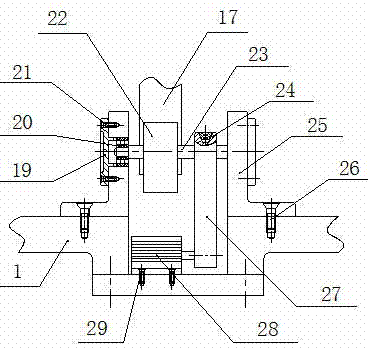

Oscillating mirror mechanism driven by cam

A cam mechanism and cam technology, applied in the direction of optical components, optics, instruments, etc., can solve the problem of high rotation accuracy and dynamic performance requirements of torque motors, difficulty in overcoming the friction and influence of return springs, and affecting the accuracy of yaw angle adjustment, etc. problem, to achieve the effect of simple structure, improved precision and guaranteed stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific example

[0072] Concrete example: take r 0 =30, a=100, b=60, the maximum swing angle of the pendulum φ max =10°, push stroke movement angle ∠1=180°, return stroke movement angle ∠2=180°; the movement law of the pendulum: both the push stroke and the return stroke are quadratic polynomial motion laws. According to the above parameters and formula (1) ~ formula (5), etc., draw the figure through MATLAB programming and finally get as follows Figure 13 The cam profile curve shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com