Shock testing machine and shock testing method

A technology of impact testing machine and impact device, which is applied in the direction of impact testing, machine/structural component testing, measuring devices, etc., and can solve problems affecting work efficiency, a large amount of debugging time, and excessive use of impact testing machines.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

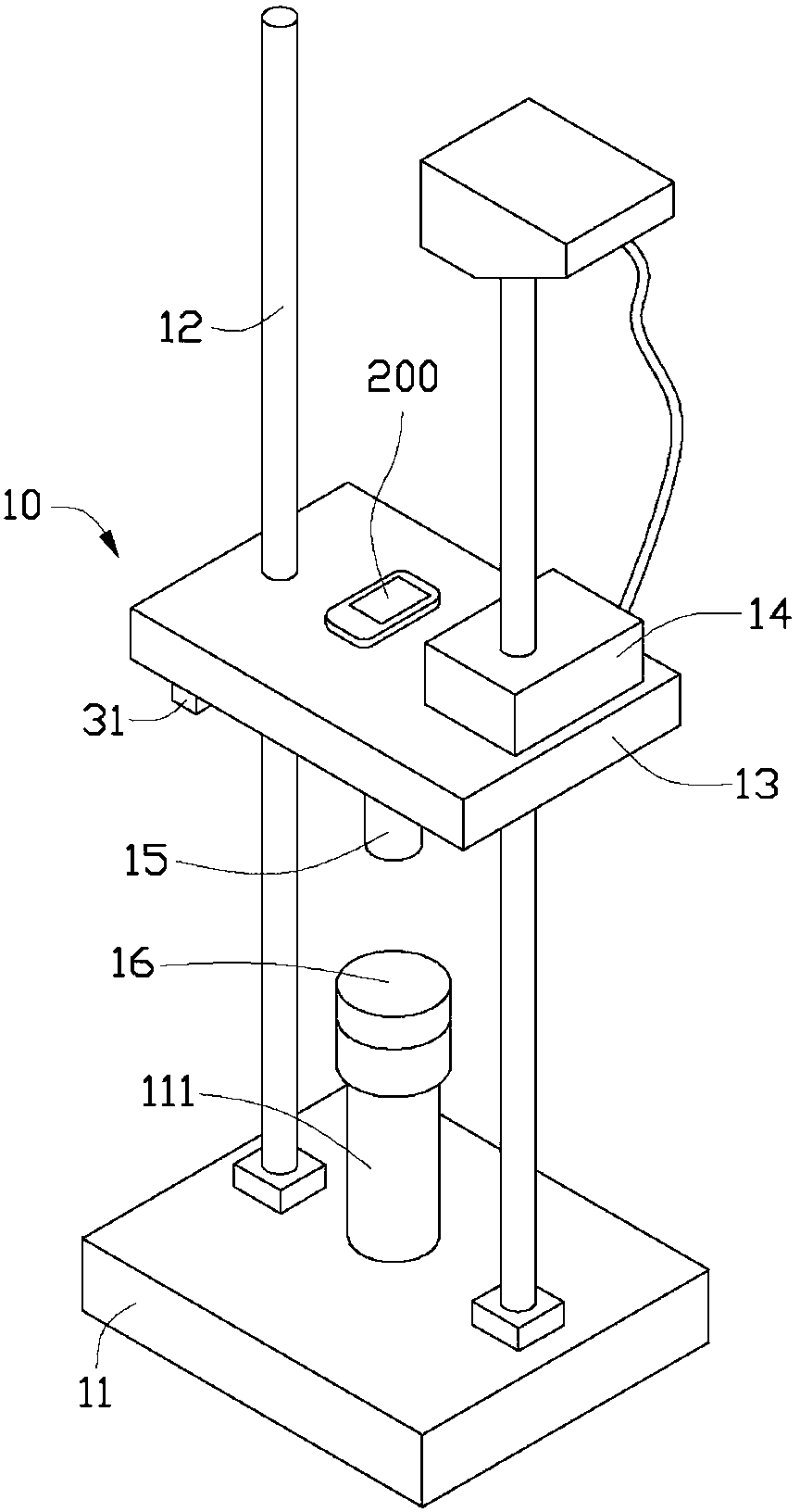

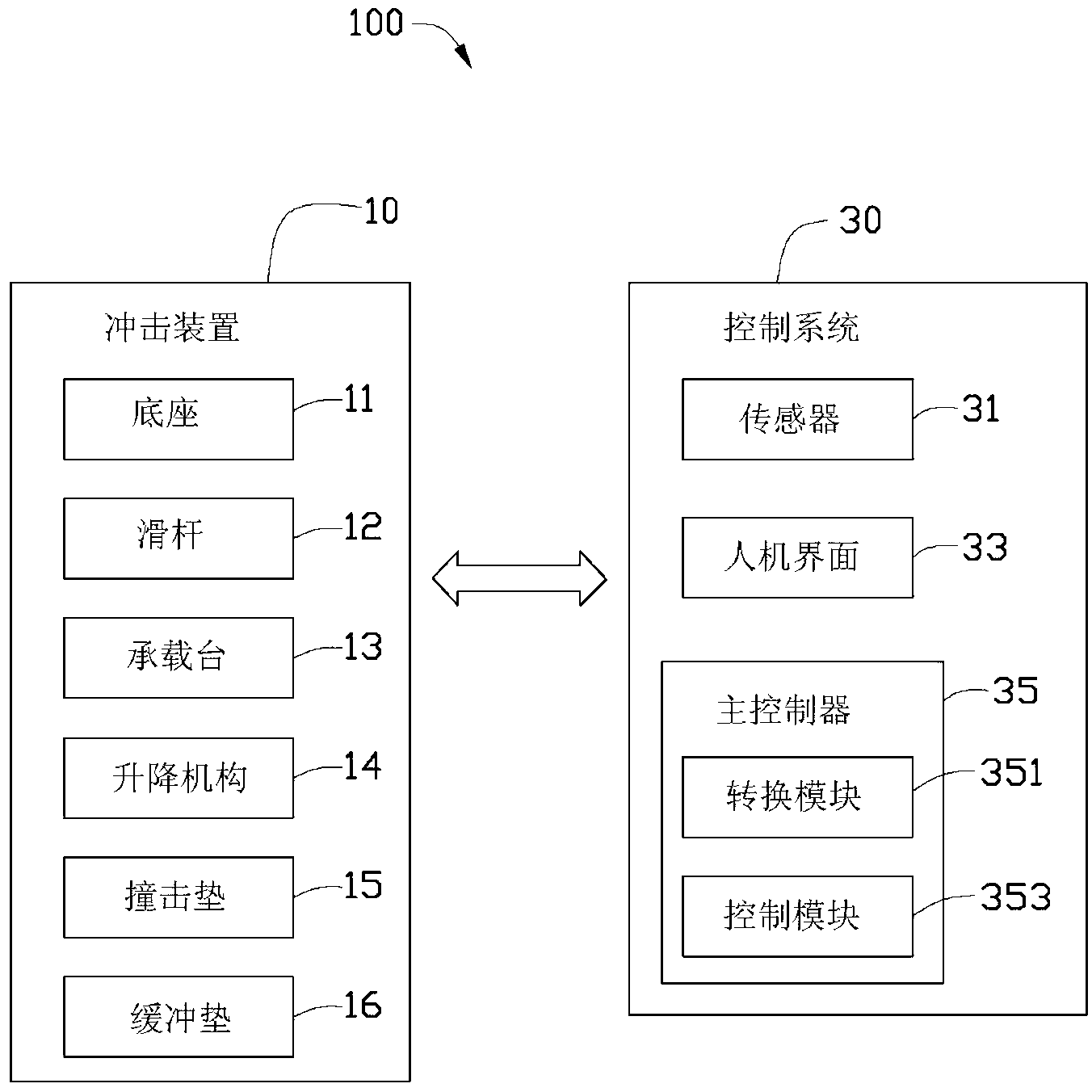

[0015] see figure 1 and figure 2 , the impact testing machine 100 according to the preferred embodiment of the present invention includes an impact device 10 and a control system 30 electrically connected to the impact device 10 .

[0016] The impact device 10 includes a base 11 , a sliding rod 12 , a bearing platform 13 , a lifting mechanism 14 , an impact pad 15 and a buffer pad 16 . A positioning block 111 is disposed on the base 11 for positioning the buffer pad 16 . In this embodiment, the number of the sliding rods 12 is two, and the two sliding rods 12 are vertically installed on the base 11 in parallel. The carrying platform 13 is used for carrying a product 200 to be impact tested, such as an electronic device. The carrying platform 13 passes through the sliding bar 12 and slides along the sliding bar 12 to approach or move away from the base 11 . The lifting mechanism 14 is fixedly connected with the carrying platform 13 for controlling the lifting of the carryi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com