Heating duct detecting robot

A pipeline inspection and robot technology, which is applied in the pipeline system, mechanical equipment, gas/liquid distribution and storage, etc., can solve the problems of high difficulty in heating pipeline inspection, complex terrain, and complex structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

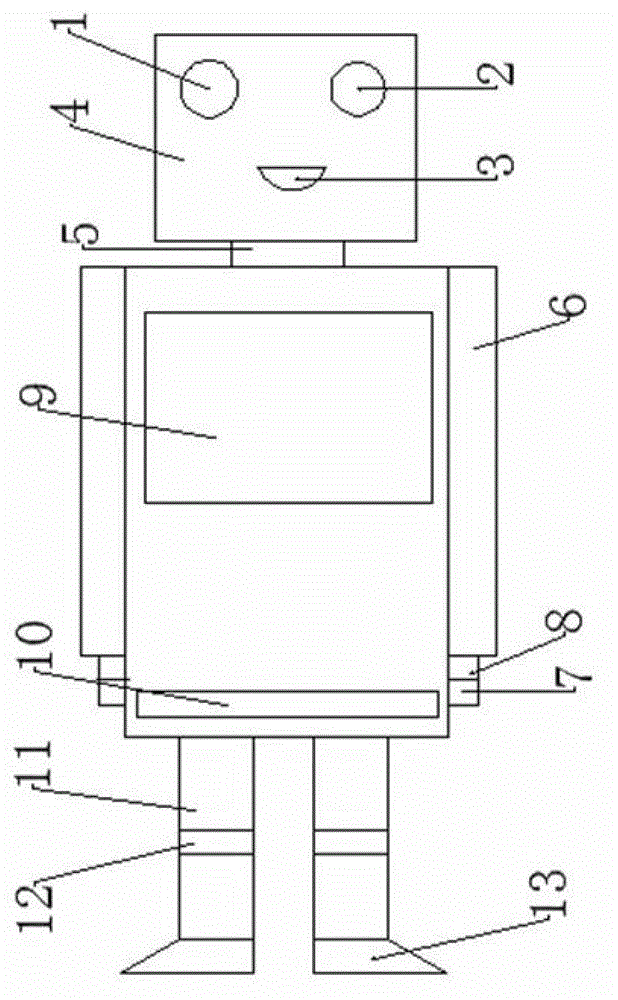

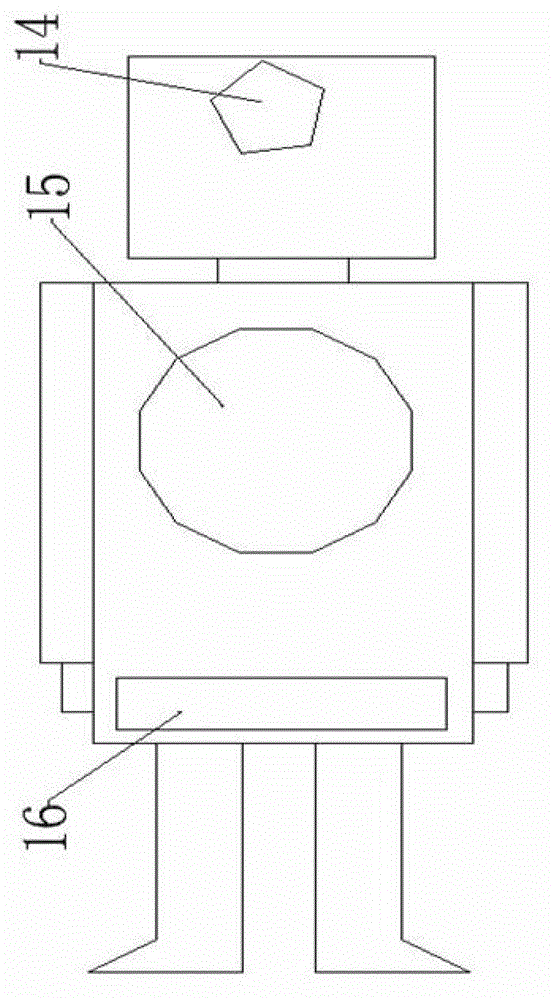

[0014] The shape of this robot is humanoid, is divided into head 4, neck 5, upper limbs 6, chest abdomen, lower limbs 11 five parts. The positions of the two eyes of the head are respectively a camera 1 and a digital temperature sensor 2, a radio transmitting and receiving device 14 is installed inside, and a loudspeaker 3 is installed in the mouth. The neck is equipped with a linkage. The upper limb is equipped with manipulator 7 and ultrasonic transmitter 8. LED display screen 9 is housed outside the chest, and the inside is industrial controller 15. The outside of the abdomen is an ultrasonic receiving device 10 and a charging device 16 . The lower limbs are mobile device 13 and linkage device 12 .

[0015] The working process of the present invention is as follows: the user starts the heating pipe detection robot through the remote contr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com