Method for producing carbon-free and thermosensitive body paper by using large proportion of chemithermomechanical pulp

A chemical-mechanical pulp, large-scale technology, used in chemical and mechanical pulp mixtures, papermaking, paper machines, etc. Thick performance, reduce production cost, ensure delicate effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

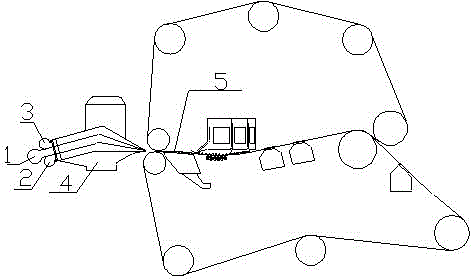

[0011] Embodiment 1: A method of producing carbon-free and heat-sensitive base paper using chemical-mechanical pulp in a large proportion, including sizing, headbox pulping, wire dehydration, press dehydration, pre-drying, coating, post-drying, calendering, In the coiling process, the raw materials used in the sizing process are chemical-mechanical pulp and chemical pulp in a ratio of 5-7:3-5. The chemical-mechanical pulp and chemical pulp in the sizing process are respectively sent to the headbox for the pulping process. In the box, the headbox in the headbox pulping process is a three-layer headbox. The chemical pulp in the sizing process is evenly distributed to the upper and lower pulp distribution systems of the headbox, and the chemical pulp flow is sent to the headbox. The middle-layer pulp distribution system, the three-layer pulp coming out of the headbox is dehydrated through the wire dehydration process, and the wire dehydration process adopts the wire part formed by...

Embodiment 2

[0012] Embodiment 2: The chemical-mechanical pulp and the chemical pulp are flowed to the three-layer headbox 4 through the sizing system according to the ratio of 7:3, wherein the chemical pulp is evenly distributed to the upper layer 3 and the lower layer 2 of the headbox in the slurry distribution system, The chemical-mechanical pulp flow is sent to the middle layer 1 of the headbox. The production of base paper is completed through sandwich forming 5 dehydration, press dehydration, pre-drying, coating, post-drying, calendering, coiling, etc. Carbon-free, heat-sensitive base paper produced according to the above-mentioned method, with a basis weight of 40g / m 2 , Thickness 0.056mm, moisture 7%, smoothness 75.2s / 68.5s, tensile index 78.4 / 34.8, tearing degree 248mN / 268mN, opacity 75%.

[0013] According to the actual needs of production, the proportion of chemical pulp and chemical mechanical pulp can be adjusted, but the proportion of chemical pulp in the proportion of pulp ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| opacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com