Thermal spraying remanufacturing method for damaged end surface of aero-engine accessory gearbox housing

An aero-engine and accessory casing technology, which is applied in coating, fusion spraying, metal material coating technology and other directions, can solve the problems of complex casing structure, damaged area of failure, damage to the end face of the casing, etc., and achieves good results. , Simple operation, the effect of troubleshooting

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The following examples will further illustrate the present invention, but do not limit the present invention thereby.

[0014] The thermal spraying remanufacturing method of the damaged end face of the casing shell of an aero-engine accessory, the process steps are:

[0015] (1) Damage to the boring part:

[0016] Withdraw all the screw piles around the shell to ensure that the threaded holes of the shell are intact; then align the end faces of the shell backed-off piles within 0.01mm, and bore out 0.2~0.4mm of the end faces (Examples 1~3 are 0.2mm, 0.3mm for 4~6).

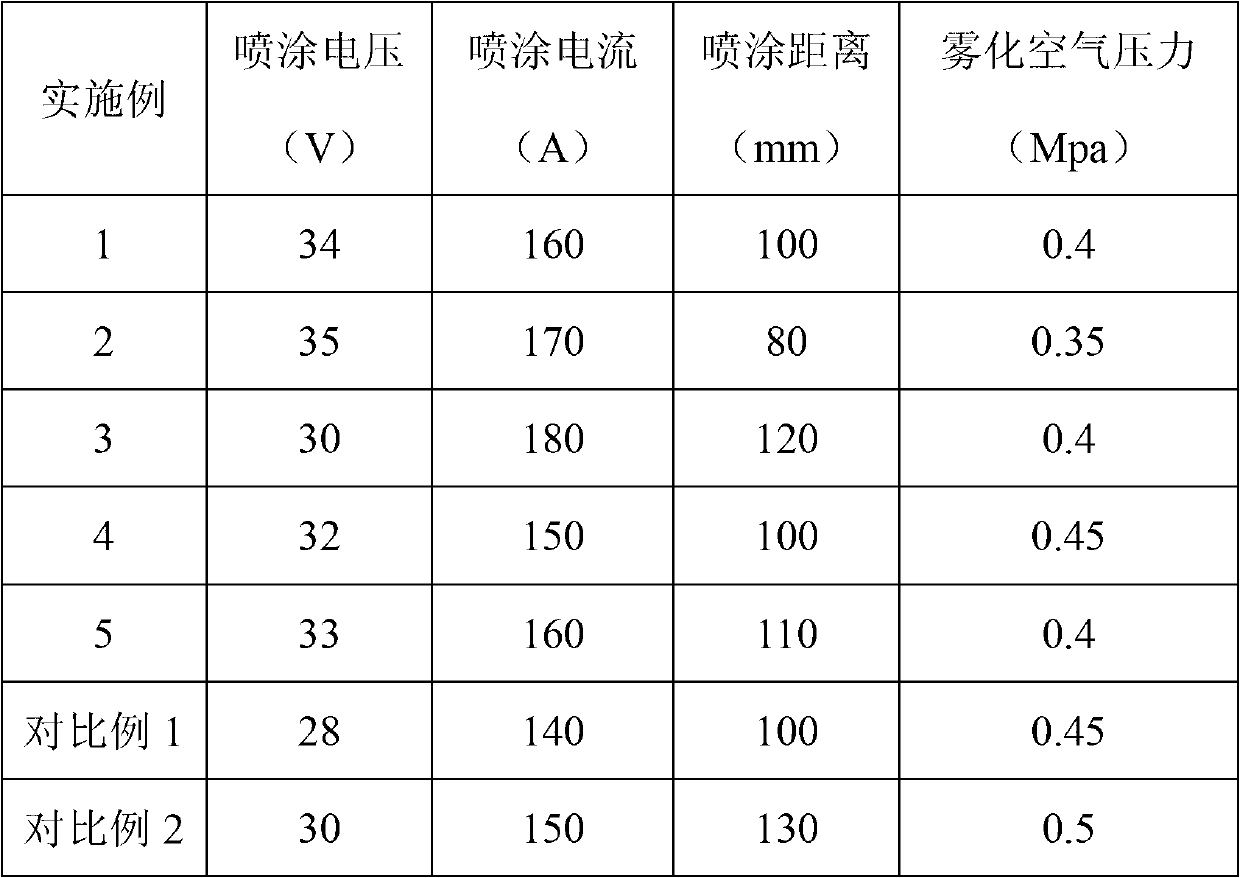

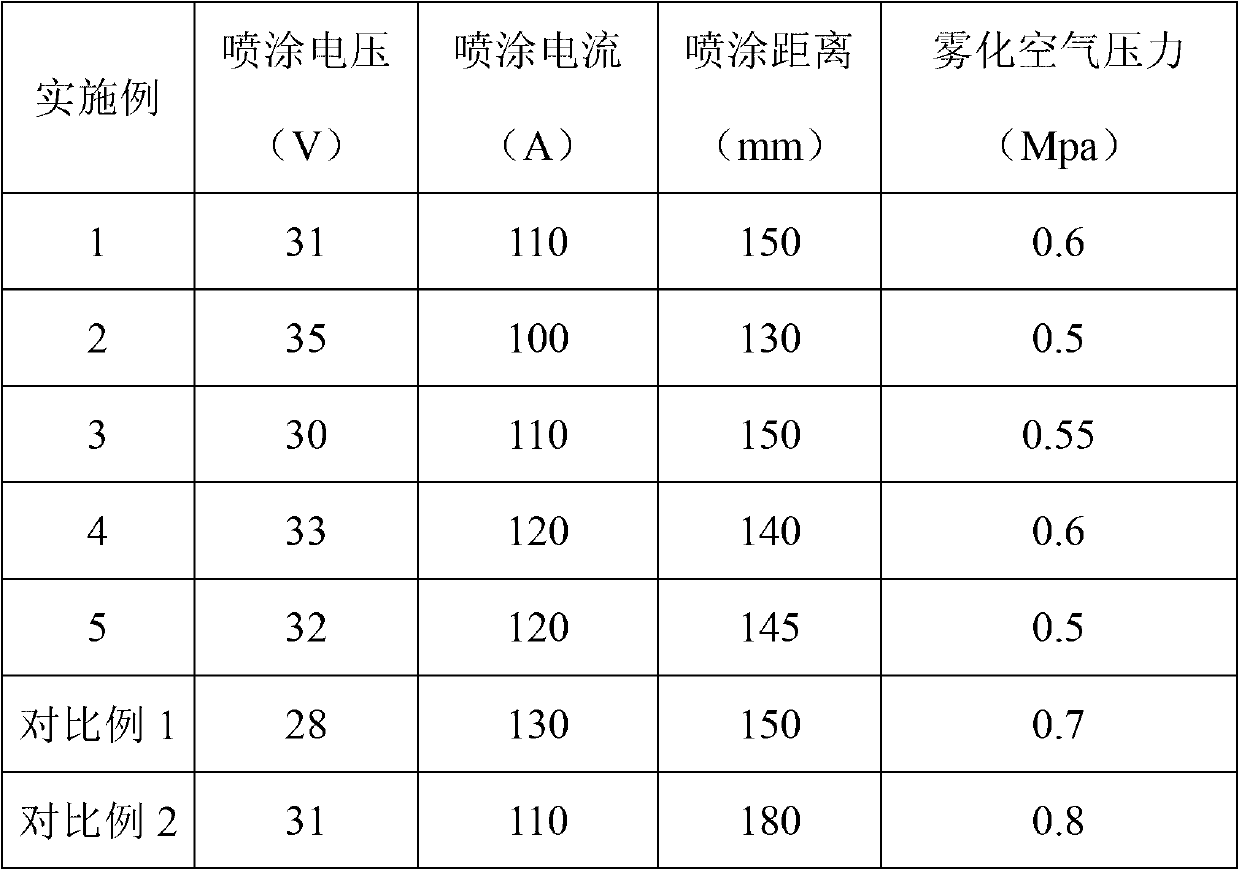

[0017] (2), thermal spray repair damage:

[0018] Scrub the surface of the shell before spraying to completely remove various oil stains;

[0019] Paste the special tape for spraying and shielding on the parts of the casing that do not require spraying for protection, and fill the screw holes that need to be protected with silicone rubber;

[0020] The parts to be sprayed are sandblasted with 20~24 mesh...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com