Automobile model switching mechanism of automobile production line

A technology of automobile production line and switching mechanism, which is applied in the direction of welding/cutting auxiliary equipment, auxiliary equipment, auxiliary welding equipment, etc. It can solve the problems of inaccurate fixture positioning, troublesome switching operation, and complicated structure, so as to ensure welding quality and clamping The effect of point stability and cost reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

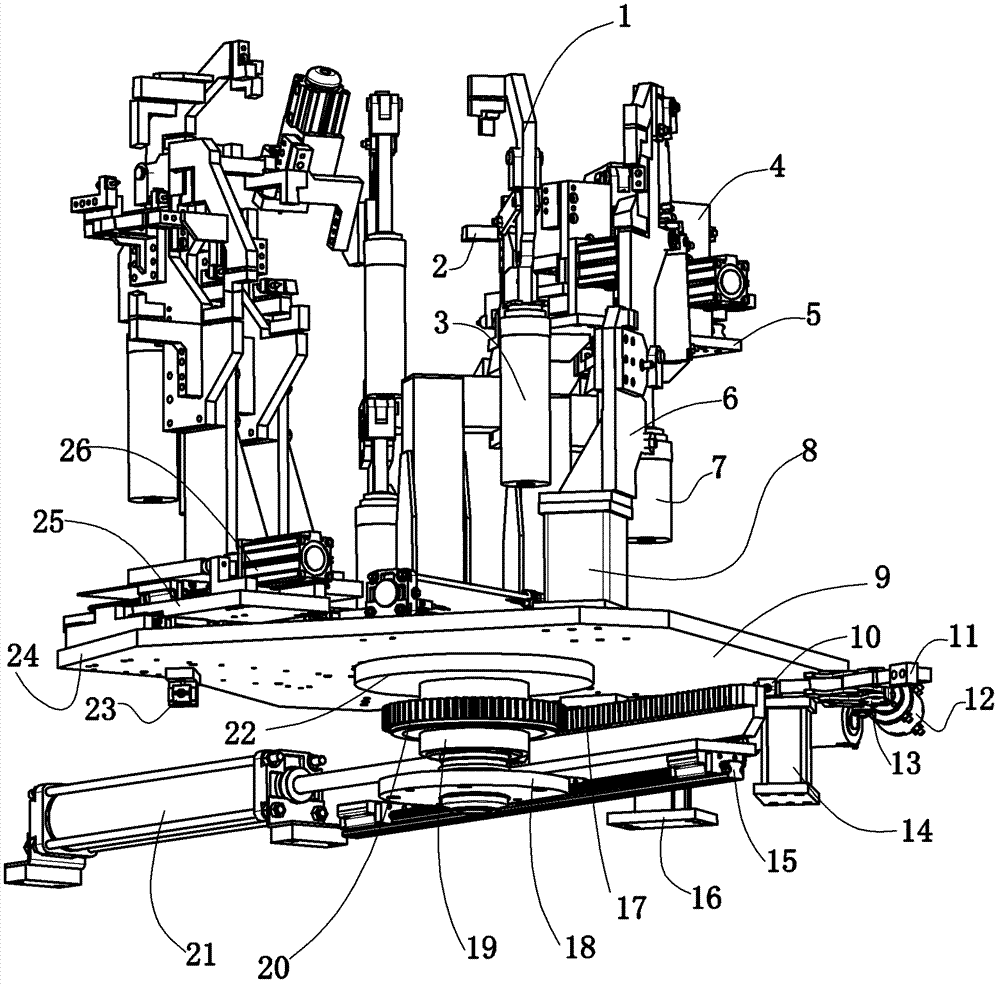

[0023] Embodiment: a kind of vehicle production line model switching mechanism (see attached figure 1 ), is arranged on the conveying track of the automobile production line through the mounting seat, the mounting plate 18 is fixed on the mounting seat, the center of the mounting plate is fixed with a bearing, and the rotating shaft 19 is fixed through the bearing. A rotating connecting plate 22 is fixed on the upper end of the rotating shaft, and the rotating connecting plate is circular, and a rotating platform 9 is fixed on the upper surface of the rotating connecting plate. The middle part of the rotating shaft is fixed with gear 20, and the piston rod end of cylinder 21, cylinder is fixed with cylinder 21, cylinder by fixed seat 16 on the mounting seat, and the tooth surface of tooth rack is meshed with the gear teeth of gear. The side portion of the rack is fixed with a slide rail 15, and the slide rail is fixed on the mounting seat through the holder.

[0024] The rota...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com