Explosive cladding method for stainless steel clad plate

A technology of stainless steel and composite plates, which is applied in the direction of non-electric welding equipment, welding equipment, metal processing equipment, etc., can solve the problems affecting the processing progress, quality and cost of composite plates, reduce the unbonded area, increase the yield, and improve Effect of Explosive Binding Rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0040] The substrate, double board and technical requirements of this example

[0041] Substrate: Q235 in the national standard GB700

[0042] Length 4050mm Width 550mm Thick 90mm

[0043] Double plate: 09Cr18Ni9 stainless steel in the national standard GB4237.

[0044] Length 4100mm, width 600mm, thickness 14 mm

[0045] The method for the explosive combination of the stainless steel clad plate comprises the following steps in sequence:

[0046] Ⅰ、 match

[0047] The Q235 base plate 2 and the 09Cr18Ni9 stainless steel cladding plate 4 that meet the national standards and technical requirements are assembled according to the requirements of the final product.

[0048] Ⅱ polished surface

[0049] Use a grinding wheel or a polishing impeller to remove oxides and impurities on the explosive joint surface of the substrate 2 and the double plate 4, and the surface roughness value of the joint surface of the substrate 2 and the double plate 4 is not greater than R a 6.3μm; t...

Embodiment 2

[0061] The doubler plate of this embodiment is 30408, and the steps of the manufacturing method are the same as that of the first embodiment, and the explosive bonding rate reaches 96%.

Embodiment 3

[0063] The base plate of this embodiment is Q345R, and the doubler plate is 06Cr13Al. The steps of the manufacturing method are the same as those of Embodiment 1, and the explosive bonding rate reaches 96%.

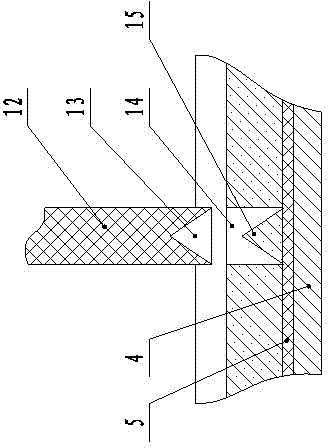

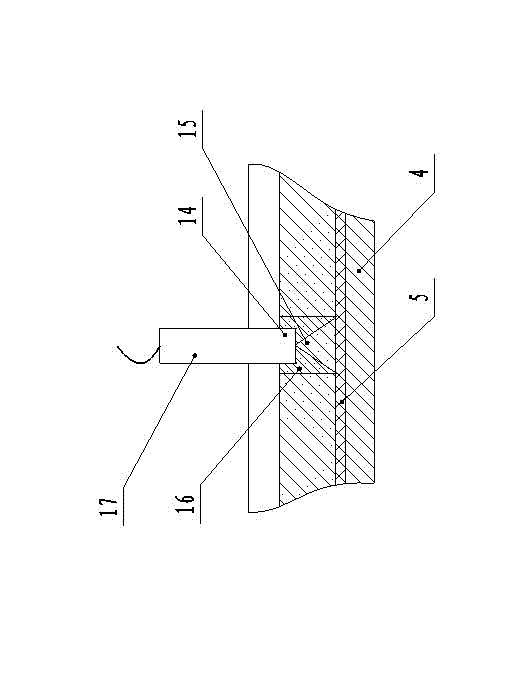

[0064] The present invention utilizes high detonation velocity (RDS) explosive 15 to fill the energy-gathering hole 13 with a cone inside, to ensure that the detonating electric detonator 16 is stable and the density of the main explosive is uniform. Utilize the energy-gathering effect to make the energy charge package, change the detonation method of the stainless steel composite plate, and quickly form a bending angle at the detonation position to realize the welding of the stainless steel and the substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com