Punching production line for punching circular tube type workpiece

A round tube-shaped production line technology, applied in the field of stamping production lines, can solve the problems of high labor intensity for operators, inability to process round tube-shaped workpieces in multiple passes, and high risk.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

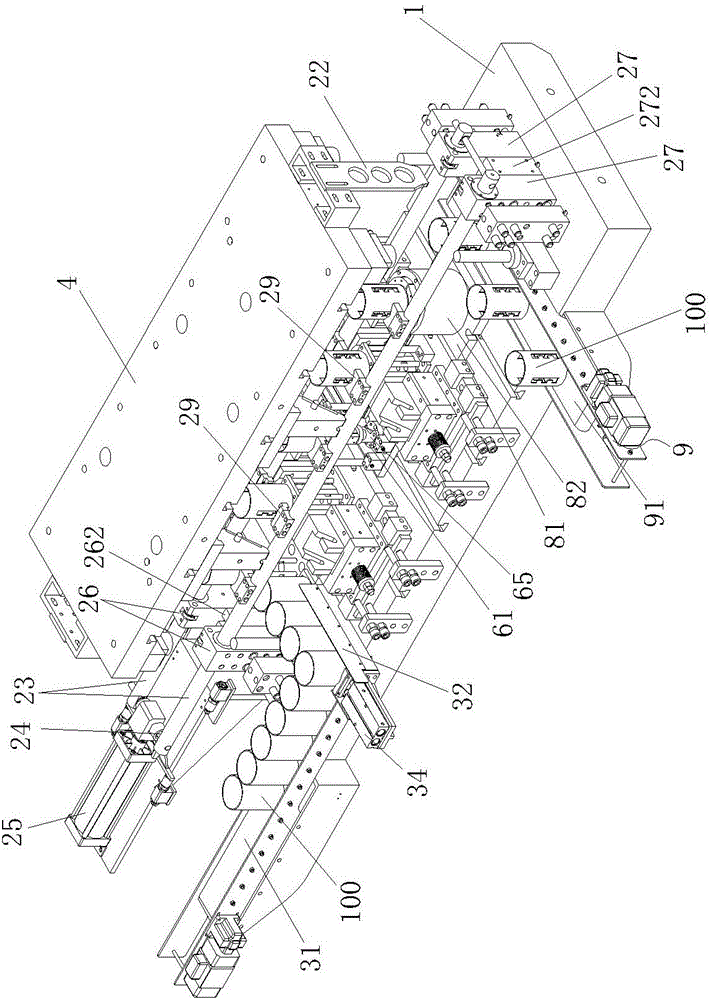

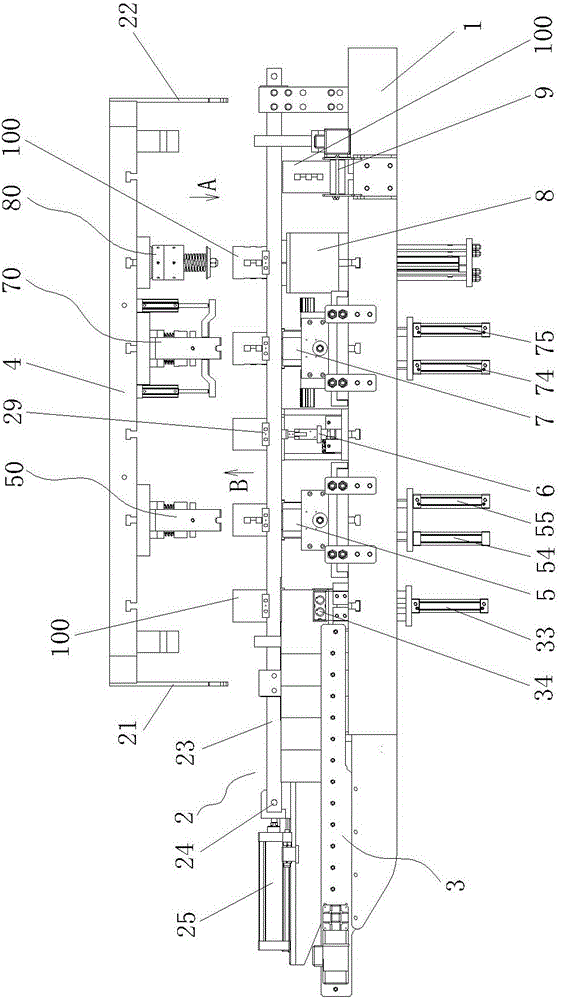

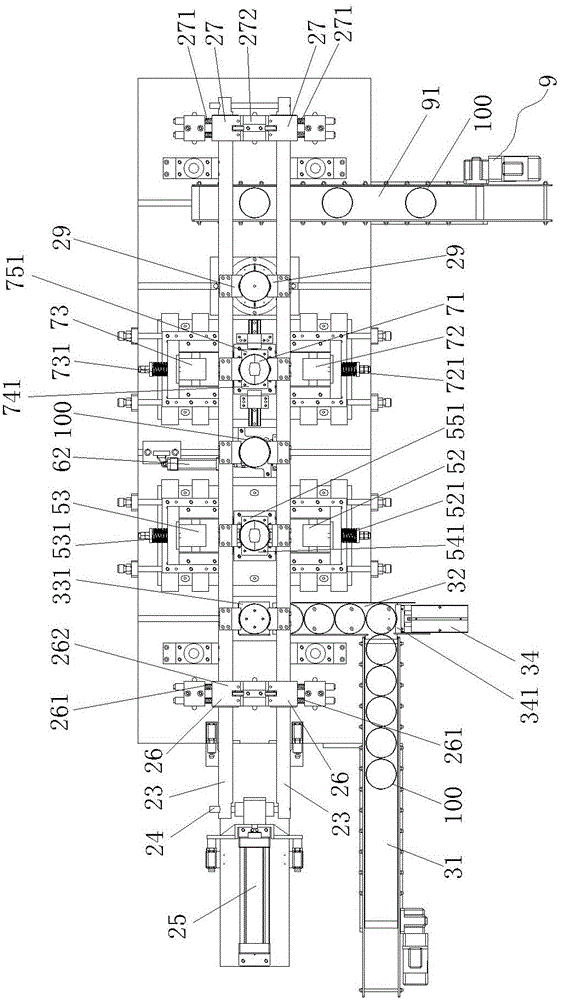

[0028] Figure 1 to Figure 10 As shown, a stamping production line for blanking circular tubular workpieces, including a press (only the workbench and the mounting seat of the slider are shown in the figure), and a circular tubular workpiece is installed on the workbench 1 of the press 100 is sequentially clamped from one station to the next station, the material transfer mechanism 2, the circular tube-shaped workpiece 100 is transported from the outside to the material transfer mechanism 2, and the feeding mechanism 3 is clamped at the initial position, and the slider 4 of the press The front support plate 21 and the rear support plate 22 are installed on the top to cooperate with the material transfer mechanism 2 to perform clamping and loosening actions;

[0029] On the press table 1 below the material shifting mechanism 2, the firs...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com