Zinc and nickel impregnation agent pulp washing filtered water recycling device

A recovery device and penetrant technology, which is applied in the field of zinc-nickel penetrant washing slurry filtration water recovery device, can solve problems such as difficulty in washing slurry and water removal, and achieve the effects of increasing filtration area, convenient recovery, and maintaining water filtration function.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

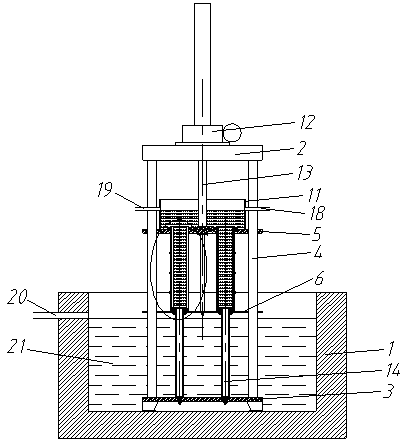

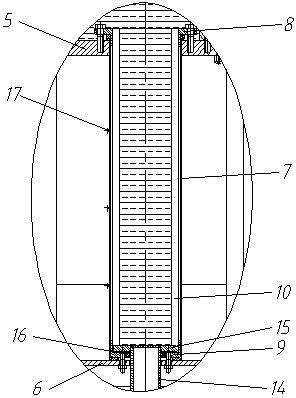

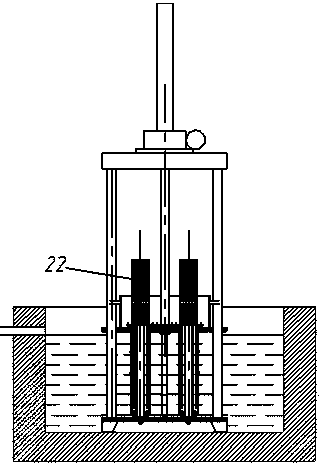

[0026] The present invention will be described in further detail below in conjunction with the accompanying drawings.

[0027] see figure 1 , figure 2 and image 3 , as can be seen from the figure, the zinc-nickel penetrating agent pulp washing filter recovery device of the present invention, it comprises clear water pool 1, is provided with frame in clear water pool 1, and frame consists of upper frame seat 2, lower frame seat 3 and some guide columns 4 constitute, the lower frame seat 3 is installed at the bottom of the clear water pool 1, and the guide column 4 is installed between the upper frame seat 2 and the lower frame seat 3; between the upper frame seat 2 and the lower frame An upper slide 5 and a lower slide 6 are arranged between the seats 3, and the upper slide 5 is located on the lower slide 6, and the upper slide 5 and the lower slide 6 are set on the guide column 4 and can slide up and down along the guide column 4 simultaneously. The upper slide plate 5 an...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com