Flatbread baking machine

A technology for baking machines and dough cakes, applied in the field of baking machines, can solve the problems of high labor intensity of operators, unfavorable market operation, low production efficiency, etc., and achieve the effects of improving production efficiency, reducing labor intensity and increasing taste.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

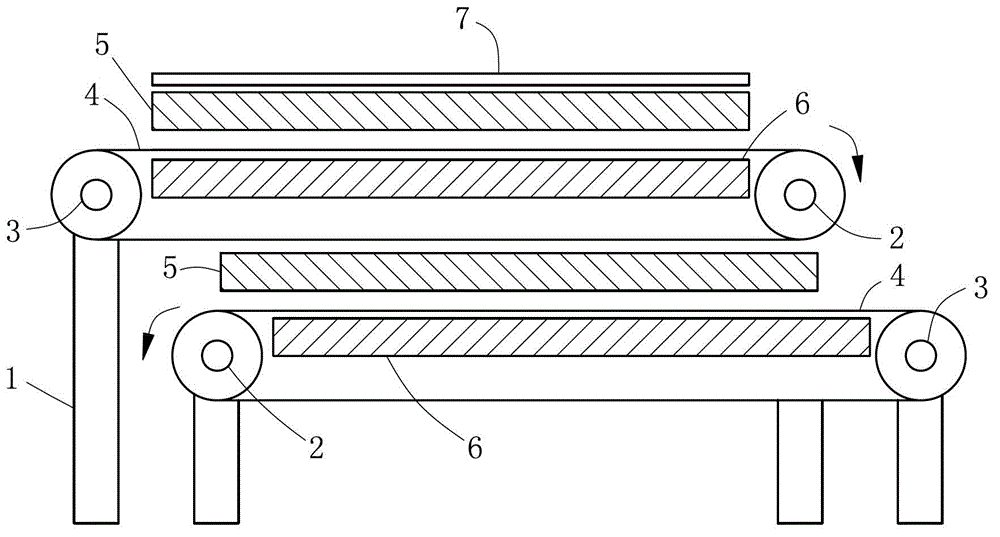

[0018] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0019] As shown in the drawings, a dough cake baking machine includes a mounting frame 1, a belt conveyor is fixedly installed on the mounting frame 1, a heating device is provided above and below the conveyor belt of the belt conveyor, and the heating device is fixedly installed on the on the mounting bracket 1. The heating device is an electric heater, or it can be a gas heater, coal heater or charcoal heater, etc. The specific form depends on the site environment. If the power is insufficient, other heating methods can still be used for baking. The heating device arranged above the conveyor belt is an upper electric heater 5 , and the heating device arranged below the conveyor belt is a lower electric heater 6 . There are at least two belt conveyors arranged up and down. The conveying directions of at least two belt conveying devices are opposite, a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com