High-rigidity and light-weight design method considering uncertainty of slide block mechanism of press machine

A lightweight design, uncertain technology, applied in computing, special data processing applications, instruments, etc., can solve the problems of two-level nested optimization, repeated calls are very time-consuming, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The present invention will be further described below in conjunction with drawings and embodiments.

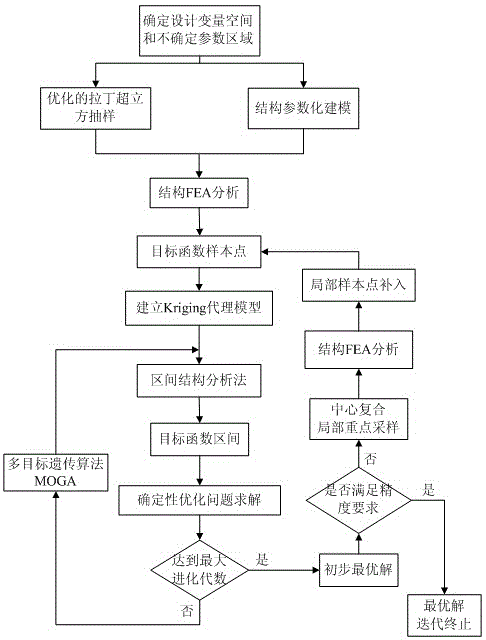

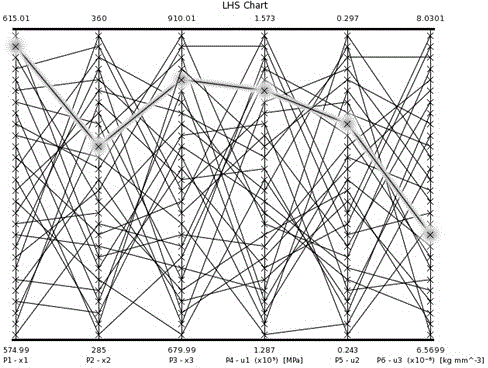

[0058] The information involved in the figure is the actual application data of the present invention in the design of a certain type of wide-table ultra-precision high-speed press. The high-rigidity and lightweight design flow chart of the press slider mechanism considering uncertainty is shown in figure 1 shown.

[0059] 1. Uncertain optimization problem description

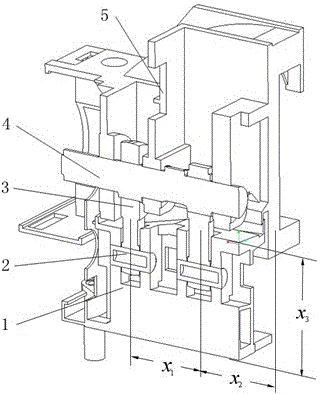

[0060] A 1 / 4 simplified model of a wide-table ultra-precision high-speed press is as follows: figure 2 As shown, it is mainly composed of 1-slider, 2-pin, 3-connecting rod, 4-main shaft and 5-beam. Take connecting rod spacing x 1 , connecting rod spacing x 2 and slider height x 3 is the design variable, according to the actual situation of the press, the value range of each design variable is:

[0061] 575mm≤x 1 ≤615mm

[0062] 285mm≤x 2 ≤360mm

[0063] 680mm≤x 3 ≤910mm

[0064] The modulus ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com