Similar material simulation test system

A simulation test system and similar material technology, applied in the field of test systems for support load and displacement changes, can solve the problem of inability to fully reflect the interaction process between support and surrounding rock, provide reliable reference, inconvenience support adaptability and type selection And other issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

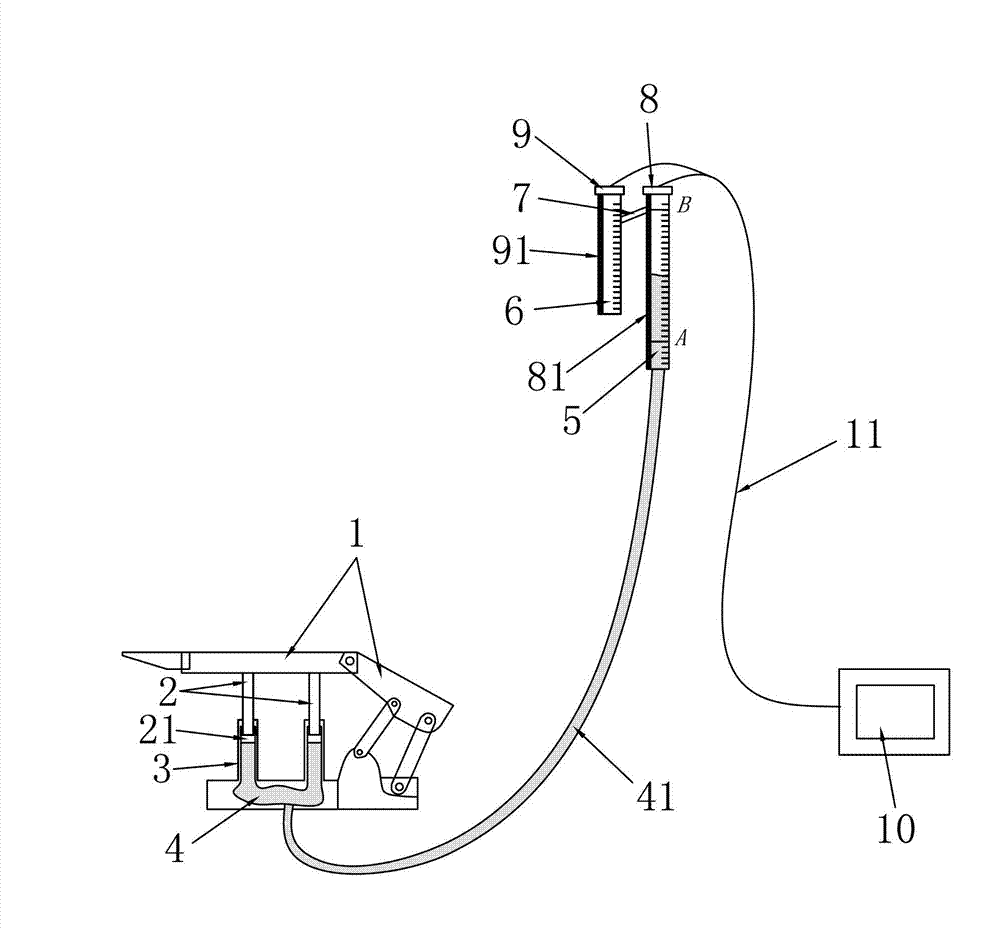

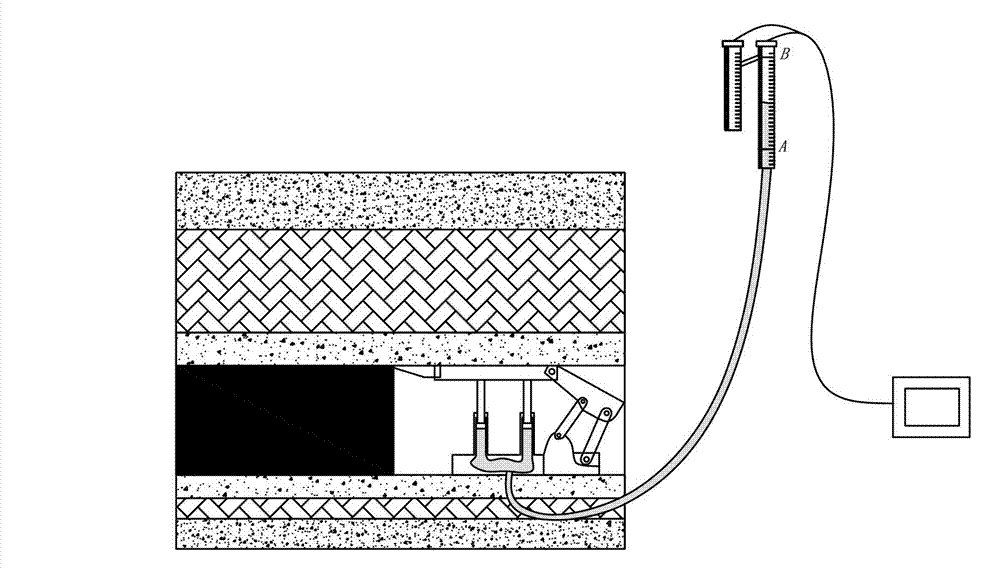

[0013] Such as figure 1 The first embodiment of the similar material simulation test system of the present invention shown includes a model support 1, and the specific structure of the model support 1 corresponds to the structure of the real support to be selected, so it will not be repeated here, and the model support 1 is fixed. There are two movable pillars 2 protruding downwards. The lower end of the movable pillars 2 is provided with a piston 21, and also includes a column 3 corresponding to the number of movable pillars 2. The pistons 21 are correspondingly sealed and slidably connected in the vertical pillars 3. The interior of the vertical pillars 3 is connected to each other to form a Liquid chamber 4, liquid chamber 4 is provided with liquid, when model support 1 moves down like this, can extrude the liquid in liquid chamber 4; Also comprise first measuring cylinder 5 and second measuring cylinder 6, first measuring cylinder 5 and the height of the second measuring c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com