Shock testing machine and method for carrying out shock test by same

An impact testing machine and impact testing technology, applied in impact testing, machine/structural component testing, measuring devices, etc., can solve problems such as reducing the service life of impact testing machines and affecting work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

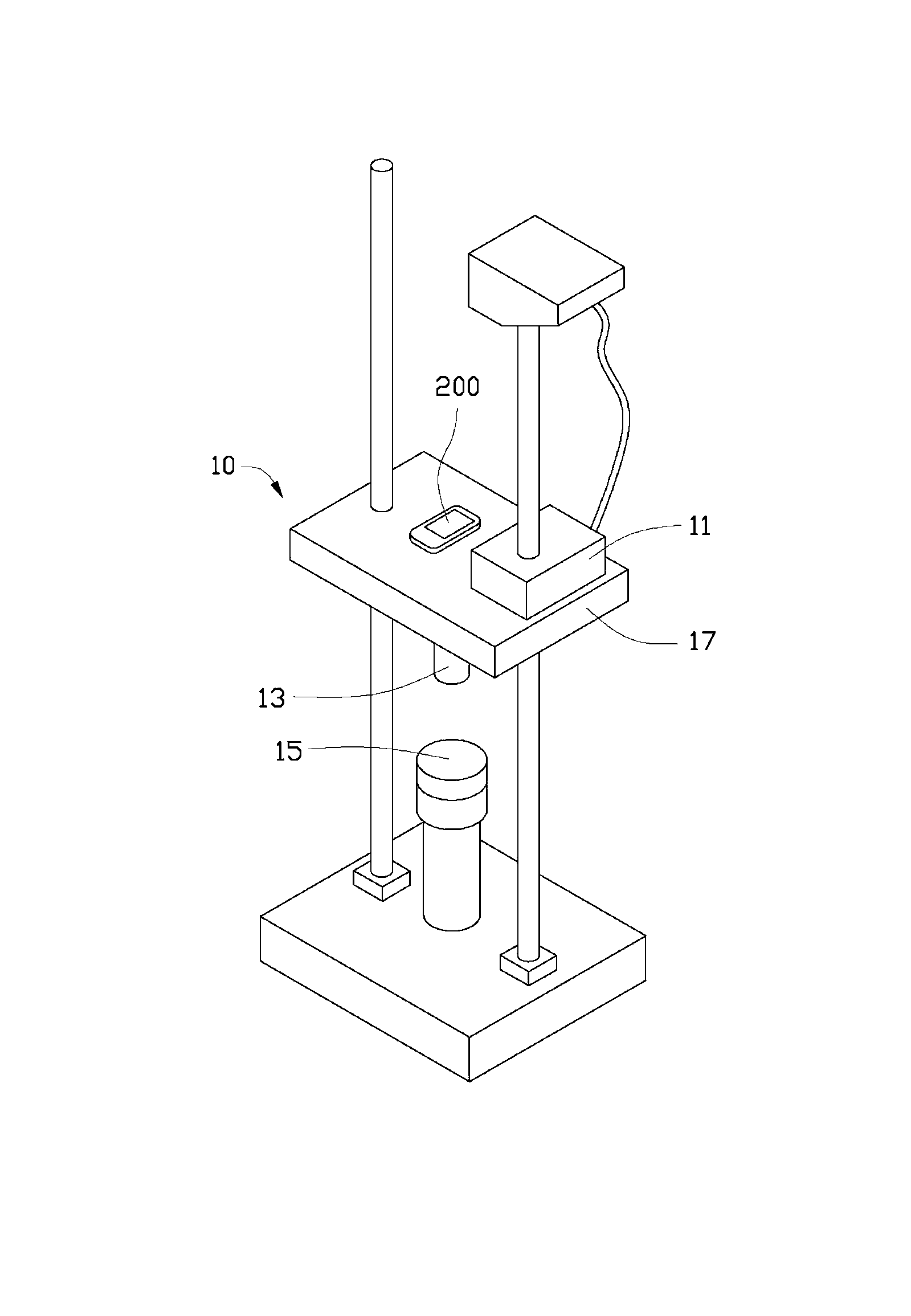

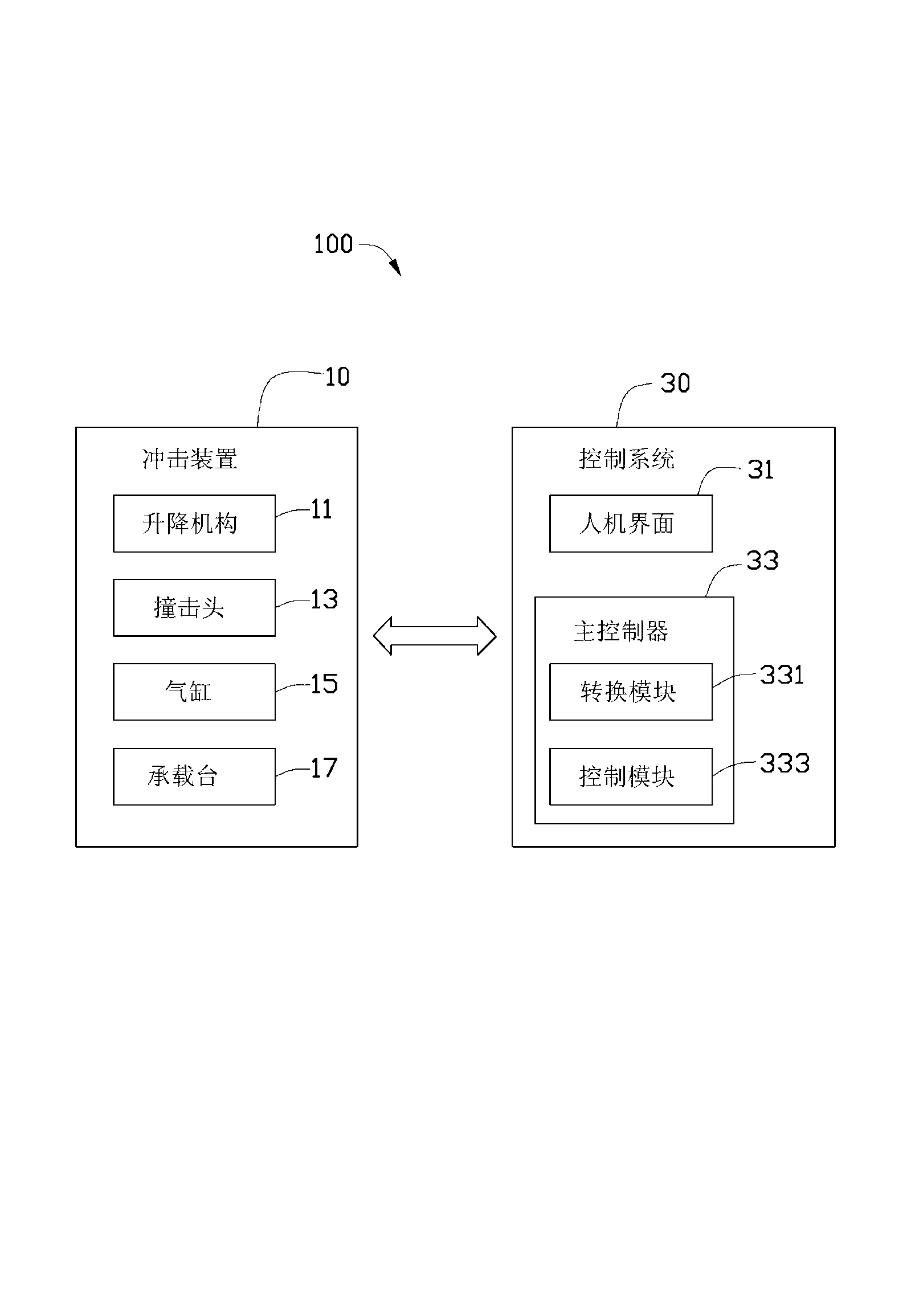

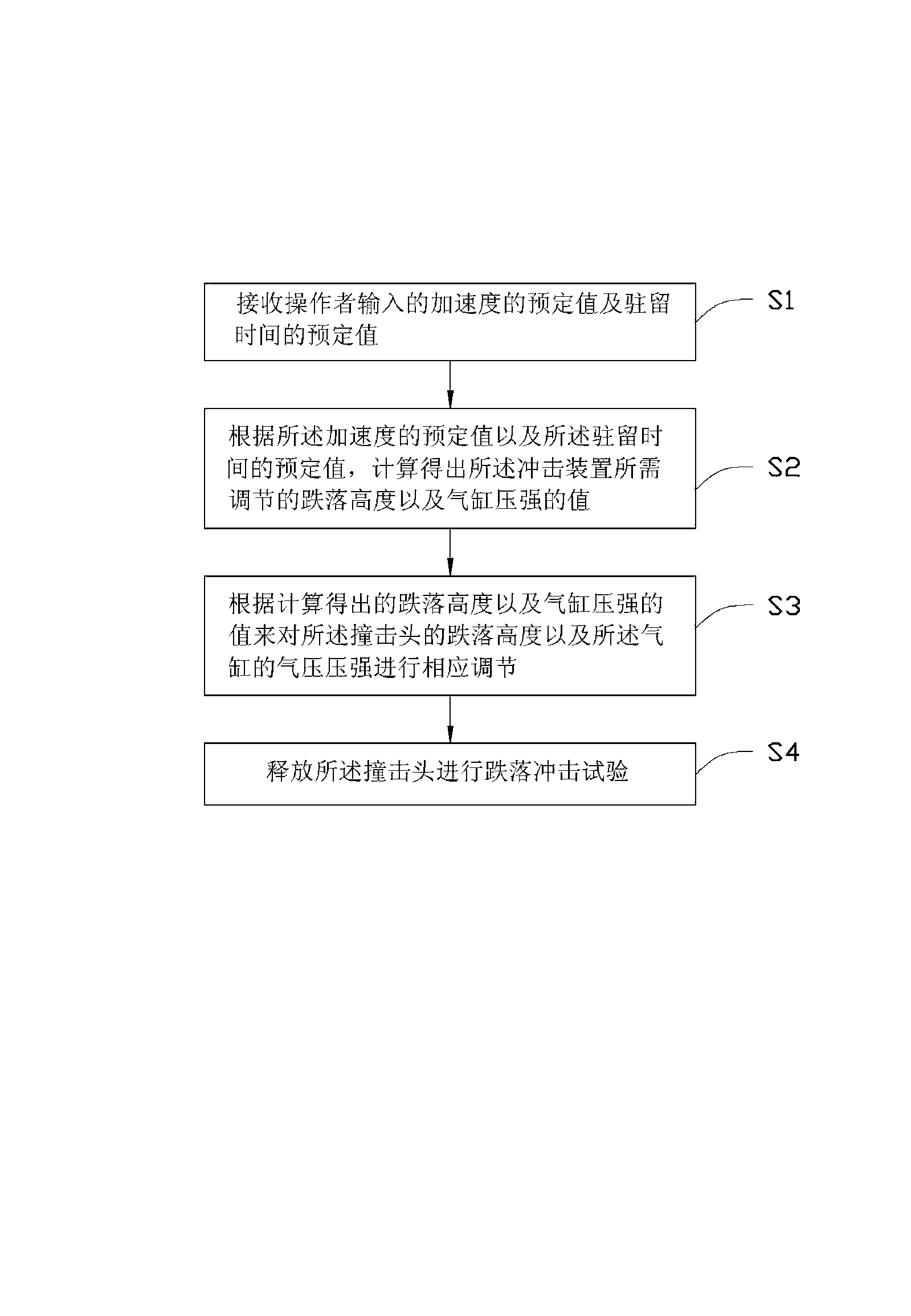

[0020] see figure 1 and figure 2 , the impact testing machine 100 according to the preferred embodiment of the present invention includes an impact device 10 and a control system 30 electrically connected to the impact device 10 .

[0021] The impact device 10 includes a lifting mechanism 11 , an impact head 13 , a cylinder 15 opposite to the impact head 13 , and a bearing platform 17 fixed to the end of the impact head 13 away from the cylinder 15 . The lifting mechanism 11 is connected to the bearing platform 17, and the lifting mechanism 11 automatically adjusts the bearing platform 17 under the control of the control system 30, thereby adjusting the distance between the end surface of the impact head 13 and the surface of the cylinder 15, that is, the drop height of the impact head 13. After the lifting mechanism 11 releases the bearing platform 17, the impact head 13 and the bearing platform 17 do free fall together until impacting the cylinder 15. 15 rebounds. In thi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com